A production process of breathable and cashmere-proof fine denier fabric

A production process and fabric technology, applied in the field of weaving and dyeing of textiles, to achieve the effect of improving the anti-down property, the feel of the down-proof fabric, and the good feel of the fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

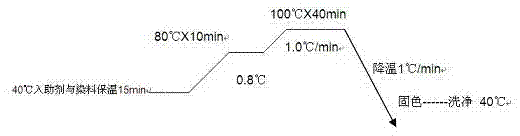

Method used

Image

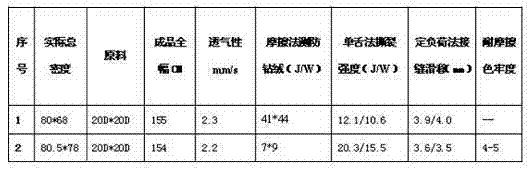

Examples

Embodiment 1

[0025] A production process of air-permeable and cashmere-proof fine denier fabric, which is carried out as follows: gray cloth weaving→cold pile treatment→desizing→dyeing→setting→water washing→calendering, in which: the warp and weft of the gray cloth are all made of 20D nylon matting FDY Filament, warp direction density 78 / cm, weft density 78 / cm.

[0026] Cold-stack treatment is to dip the gray cloth in the cold-stack padding solution in the padding tank of the padding car for padding treatment, then wrap and seal it, and stack the sealed cloth rolls on the cold-stack rack for 24 hours, while keeping the cloth The roll rotates slowly at a speed of 16m / min; the padding liquid in the padding tank is made of H 2 o 2 , NaOH, and refining agent are mixed at a weight ratio of 10:20:2, and an aqueous solution prepared by adding 30 times the total weight of the three deionized water, wherein the refining agent is refining agent TK-1.

[0027] Loose open-width desizing is used for ...

Embodiment 2

[0033] A production process of air-permeable and cashmere-proof fine denier fabric, which is carried out as follows: gray cloth weaving→cold pile treatment→desizing→dyeing→setting→water washing→calendering, in which: the warp and weft of the gray cloth are all made of 20D nylon matting FDY Filament, warp direction density 78 / cm, weft density 78 / cm.

[0034] Cold-stack treatment is to dip the gray cloth in the cold-stack padding solution in the padding tank of the padding car for padding treatment, then wrap and seal it, and stack the sealed cloth rolls on the cold-stack rack for 24 hours, while keeping the cloth The roll rotates slowly at a speed of 17m / min; the padding liquid in the padding tank is made of H 2 o 2 , NaOH, and refining agent are mixed in a weight ratio of 10:20:2, and an aqueous solution prepared by adding 31 times the total weight of the three deionized water is prepared, wherein the refining agent is refining agent TK-1.

[0035] Loose open-width desizing ...

Embodiment 3

[0041] A production process of air-permeable and cashmere-proof fine denier fabric, which is carried out as follows: gray cloth weaving→cold pile treatment→desizing→dyeing→setting→water washing→calendering, in which: the warp and weft of the gray cloth are all made of 20D nylon matting FDY Filament, warp direction density 78 / cm, weft density 78 / cm.

[0042] Cold-stack treatment is to dip the gray cloth in the cold-stack padding solution in the padding tank of the padding car for padding treatment, then wrap and seal it, and stack the sealed cloth rolls on the cold-stack rack for 24 hours, while keeping the cloth The roll rotates slowly at a speed of 16m / min; the padding liquid in the padding tank is made of H 2 o 2 , NaOH, and refining agent in a weight ratio of 10:20:2, and add 33 times the total weight of the three deionized water to prepare an aqueous solution, wherein the refining agent is refining agent TK-1.

[0043] Loose open-width desizing is used for desizing, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com