Biphenyl acetylene blue phase liquid crystal composite material and production method

A technology of blue-phase liquid crystal and composite materials, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of increased driving voltage of blue-phase liquid crystal materials, poor polymer stability, and increased manufacturing difficulty, and achieves large optical omnidirectionality. The effect of anisotropy and dielectric anisotropy, good electro-optical properties, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

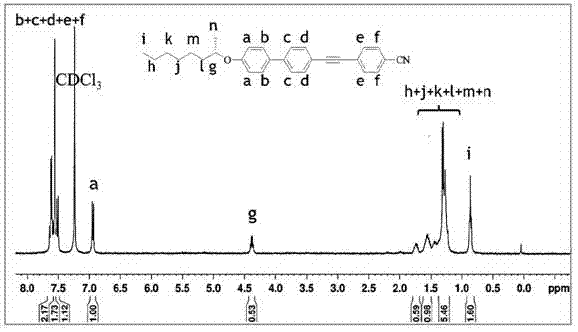

[0030] Embodiment 1 Preparation of at least one biphenyl alkyne liquid crystal compound

[0031] This embodiment is based on R1 * for R 2 for -H,R 3 for -H,R 4 Take -CN as an example to illustrate the synthesis method of biphenyl alkyne liquid crystal compounds.

[0032] Step 1) Phenylacetylation reaction: Dissolve 3.6g of 4-(7-methyl)heptyloxybiphenyl bromide in 30ml of tetrahydrofuran and 30ml of triethylamine mixed solution, place in the reactor under argon protection, and then add 10ml of alkynyl-terminated trimethylsilyl was heated up to 80°C; 140mg of triphenylphosphorous palladium dichloride and 228mg of cuprous iodide were added. Under the protection of argon, the reaction was refluxed for 12 hours. After the reaction was stopped, the solvent was distilled off under reduced pressure, and then purified by column chromatography. The developer was a mixed solvent of n-hexane and dichloromethane with a volume ratio of 4:1. The solvent was removed to obtain 2.5 g of...

Embodiment 2C5

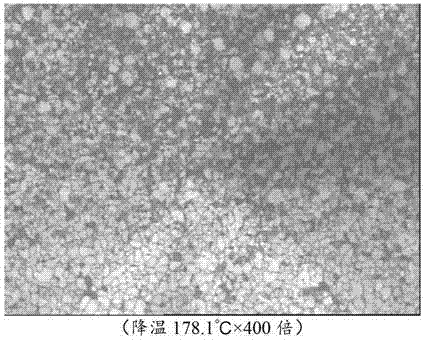

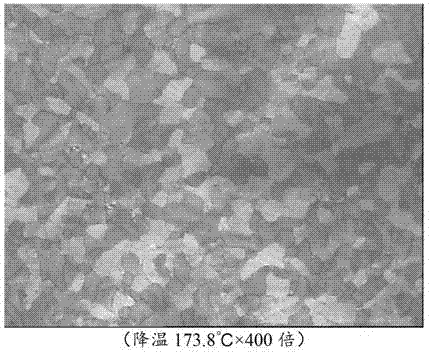

[0036] Embodiment 2C5 series biphenylene blue phase liquid crystal composite material

[0037] This embodiment is to use at least one C5 series biphenyl alkyne liquid crystal compound, which is represented by R 1 * for R 2 -H or -F, R 3 -H or -F, R 4 for -CN. The at least one C5 series biphenylene liquid crystal compound in this embodiment is the following three types:

[0038]

[0039] The preparation of the C5 series biphenyl alkyne blue phase liquid crystal composite material is to select at least one of the C5 series biphenyl alkyne liquid crystal compounds, and add different amounts of chiral compounds therein, such as adding the chiral compound ISO(6OBA) 2 , chiral compound S1011, and at least one of chiral compound S811 are fully mixed uniformly by using, for example, an ultrasonic method. Wherein, in this embodiment, the mass percentage of at least one C5 series biphenyl alkyne liquid crystal compound is 75% to 90%, and the mass percentage of at least one ch...

Embodiment 3

[0042] Example 3 C8 series biphenylene blue phase liquid crystal composite material

[0043] This embodiment is to use at least one C8 series biphenyl alkyne liquid crystal compound, which is represented by R 1 * for R 2 -H or -F, R 3 -H or -F, R 4 for -CN. The at least one C8 series biphenylene liquid crystal compound in this embodiment is the following three types:

[0044]

[0045] The preparation of the C8 series biphenyl alkyne blue phase liquid crystal composite material is to select at least one of the C8 series biphenyl alkyne liquid crystal compounds, and add different amounts of chiral compounds therein, such as the chiral compound ISO(6OBA) 2 , chiral compound S1011, and at least one of chiral compound S811 are fully mixed uniformly by using, for example, an ultrasonic method. Wherein, in this embodiment, the mass percentage of at least one C8 series biphenyl alkyne liquid crystal is 75% to 90%, and the mass percentage of at least one chiral compound P c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com