Polymeric adsorbent for removing formaldehyde and preparation method thereof

A technology for removing formaldehyde and adsorbing resins, applied in chemical instruments and methods, and other chemical processes, can solve the problems of short adsorption period and achieve low overall cost, significant social and environmental benefits, and high formaldehyde adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

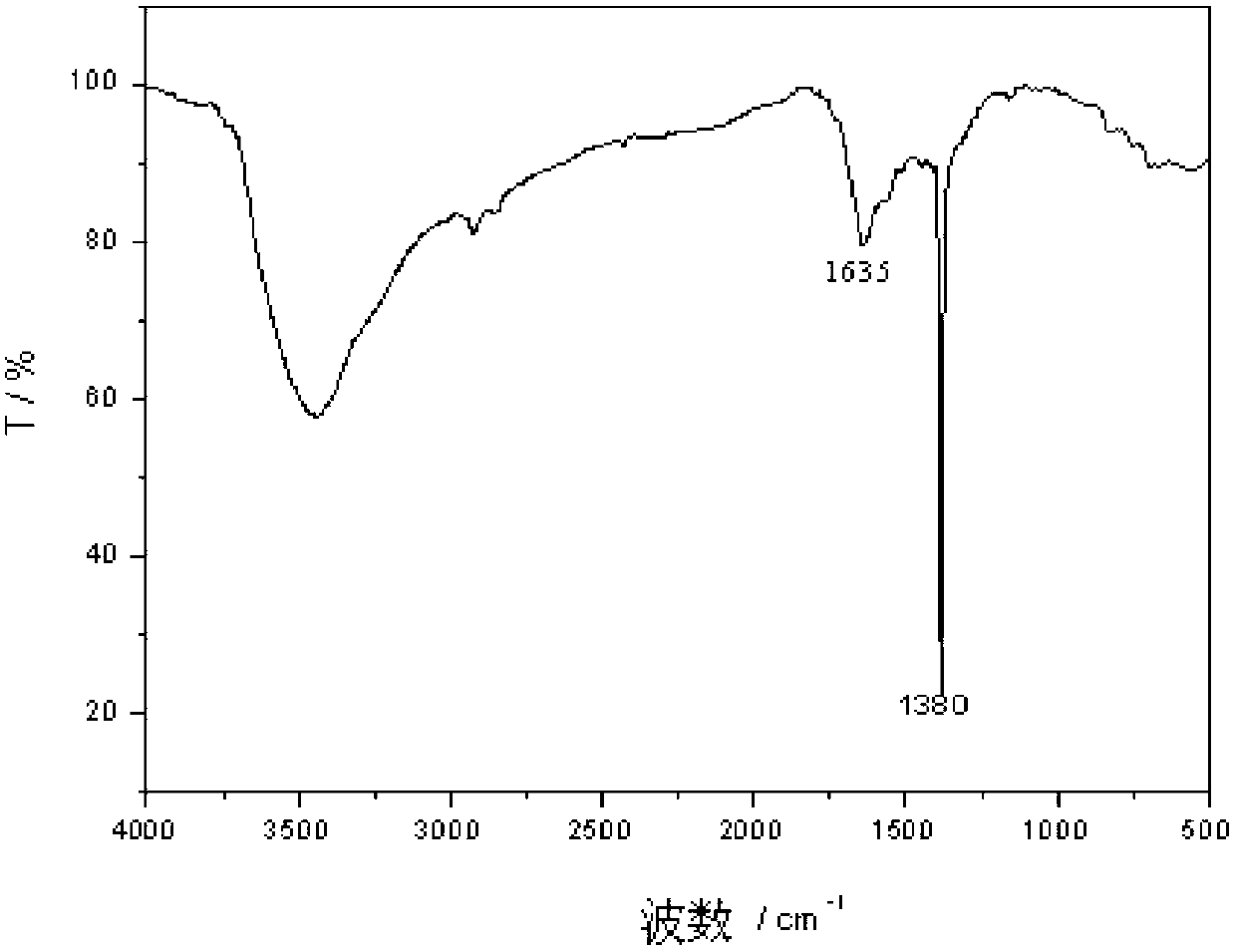

Image

Examples

Embodiment 1

[0046] a. Mix 21g of melamine with 33g of polyacryloyl chloride (molecular weight: about 1000), and control it under 20°C for 0.5 hours of ultrasonic treatment to obtain a uniformly mixed slurry;

[0047] b. React the above-mentioned slurry at 60°C for 3 hours under stirring to obtain a pre-crosslinked thick slurry;

[0048] c. Mix 200mL of o-dichlorobenzene, 120mL of xylene, and 12g of linear polystyrene with a molecular weight of 50,000 as the oil phase, and add 30g of the pre-crosslinked thick slurry obtained in step (b) into the oil phase and mix to control polymerization The temperature was 90°C, the reaction was stirred for 8 hours, suction filtered and soaked in methanol, and then washed with water to obtain 43 g of gel resin beads;

[0049]d. Measure 20 g of the gel resin beads obtained in step (c) and pack into an ion-exchange column, elute with 500 grams of 0.5mol / L hydrochloric acid aqueous solution, and then wash with water until nearly neutral, and formaldehyde is...

Embodiment 2

[0052] a. 28g of melamine was mixed with 12g of tetraethylenepentamine and 65g of phthalic anhydride, and ultrasonically treated for 0.5 hours below 20 degrees to obtain a uniformly mixed slurry;

[0053] b. Control the above-mentioned treated slurry at about 40°C and stir for 4 hours to obtain a pre-crosslinked thick slurry;

[0054] Step (c) is changed to control the polymerization temperature at 70°C, and stir the reaction for 14 hours.

[0055] Step (d) is the same as in Example 1.

Embodiment 3

[0057] Steps b, c, and d are the same as in Example 2; step a is changed to 30 g of melamine and 10 g of triethylenetetramine, the crosslinking agent is 40 g of glutaraldehyde, and 50 mL of N,N-dimethylformamide is added as a solvent at the same time. Others are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com