Efficient and comprehensive utilization method and device of filter mud for sugar making

A sugar-making filter mud, high-efficiency technology, applied in pyrolysis treatment of sludge, food industry wastewater treatment, calcium/strontium/barium oxide/hydroxide, etc. It can solve problems such as large quantities and achieve the effect of solving difficult problems, simple steps and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

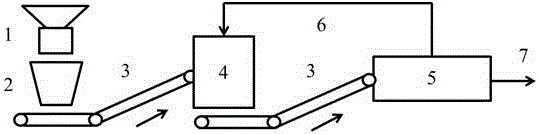

[0022] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes the filter mud outlet 1 connected to the plate and frame filter press device, the filter mud outlet 1 is connected to the crushing device 2, and the bottom outlet of the crushing device 2 is connected to the inlet of the fluidized bed drying device 4 through the conveying device 3, and the fluidized bed is dried The outlet at the bottom of the device 4 is connected to the inlet of the calcination device 5 through the conveying device 3 ; the calcination device 5 is connected to the fluidized bed drying device 4 through the waste heat recovery device 6 .

[0023] A crushing device 2 is added at the filter mud outlet 1 of the sugar workshop to crush the filter mud after the plate and frame filter press into large pieces, which facilitates the evaporation of water in the filter mud and reduces the energy consumption in the later calcination process; after crushing The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com