Needle shaped nanometer zeolite material prepared from metakaolin, and method and applications thereof

A nano-zeolite, metakaolin technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of limited types of pollutants, insufficient ability to remove pollutants, and ability to remove organic pollutants. Not strong and other issues, to achieve the effect of obvious social and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

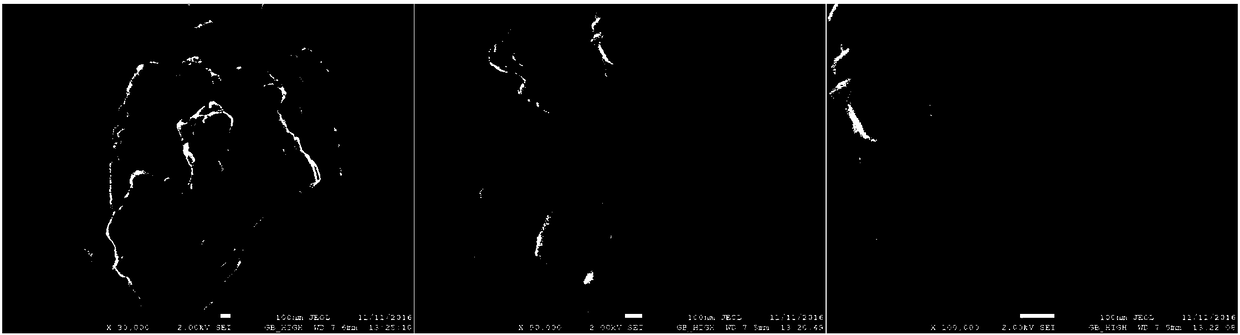

[0027] Weigh 5.0 g of metakaolin powder, mix with 30 mL of 2 mol / L sodium hydroxide solution, stir and react for 30 min to obtain a suspension slurry. The reaction solution was transferred to a stainless steel reactor for sealed storage, and then placed in an oven at 180° C. for hydrothermal reaction for 20 h. After the reaction product is cooled to room temperature, repeat centrifugation washing with deionized water three times. The test conditions of centrifugal washing are: centrifuge at 8000r / min for 5min, and dry the final product in an oven at 105°C for 6h to obtain needle-shaped Nano zeolite material, scanning electron microscope picture as figure 1 and 2 shown. figure 1 The raw material of metakaolin is sheet or layered structure, and after adding sodium hydroxide through hydrothermal reaction, the morphology of the raw material is changed from figure 1 The sheet-like structure in figure 2 needle-like nanostructures in , and the composition is transformed into zeo...

Embodiment 2

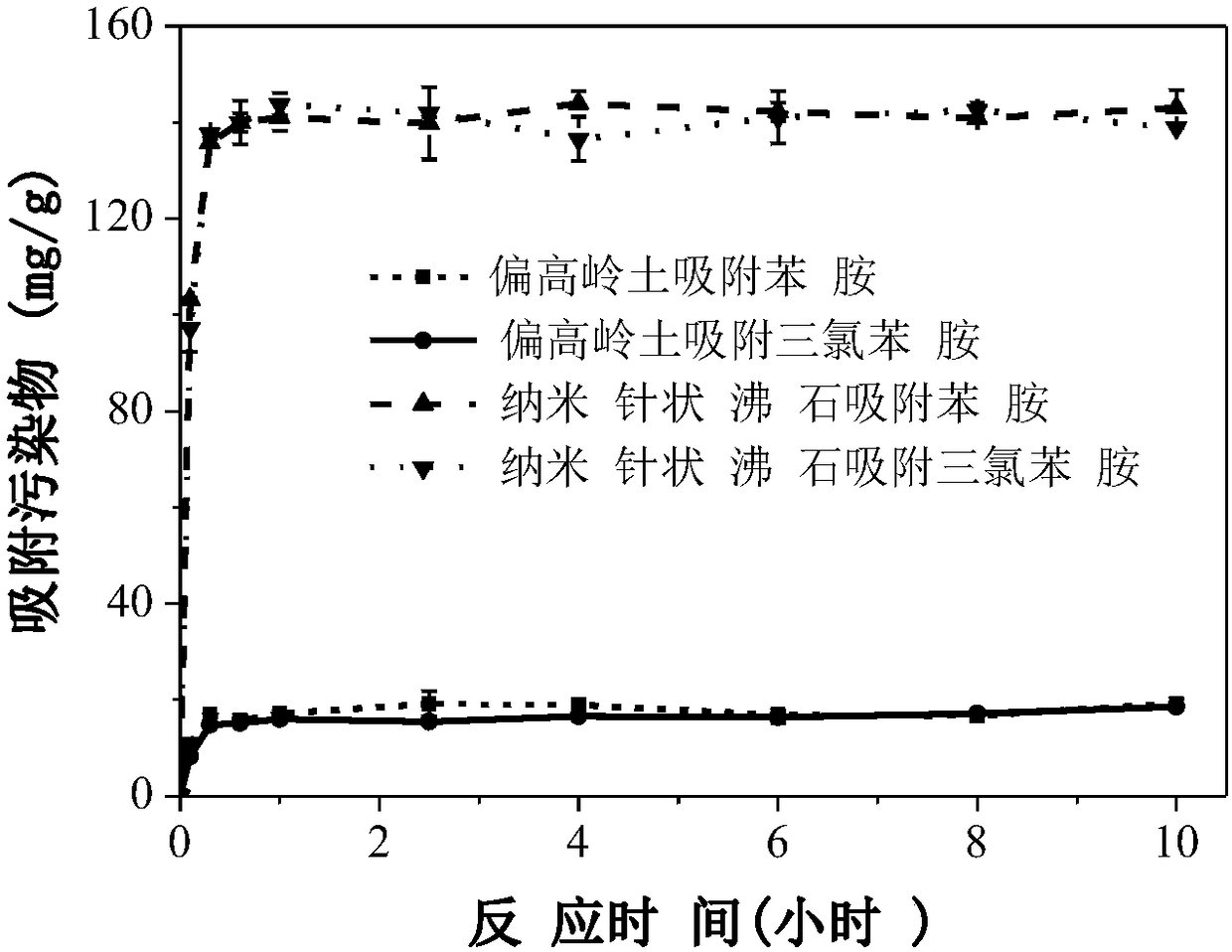

[0029] Treatment of organic pollutant waste water: take by weighing the needle-shaped nano-zeolite material prepared in Example 1 with a weight of 0.1g, add 50mL of aniline solution or trichloroaniline solution with an initial concentration of 400mg / L respectively, at a speed of 200 rpm Equilibrium reaction on a shaker for 10 h, the pH of the reaction solution is 7.2, and the reaction temperature is 25 ° C, the adsorption kinetic curves of acicular nano-zeolite materials for aniline and trichloroaniline are as follows image 3 shown. Depend on image 3 It can be seen that the needle-shaped nano-zeolite material reaches the adsorption equilibrium in about 1 hour, and the maximum adsorption capacities for aniline and trichloroaniline are: 142.95mg / g and 138.93mg / g, respectively.

Embodiment 3

[0031] Treatment of organic pollutant wastewater: weigh 0.1g of metakaolin, add them to 50mL of aniline solution or trichloroaniline solution with an initial concentration of 400mg / L, and equilibrate the reaction on a shaking table with a rotation speed of 200r / min for 10h. The pH of the reaction solution was 7.2, and the reaction temperature was 25° C., and the adsorption kinetic curves of metakaolin to aniline and trichloroaniline were obtained. The maximum adsorption capacities of metakaolin for aniline and trichloroaniline are 19.16mg / g and 18.53mg / g, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com