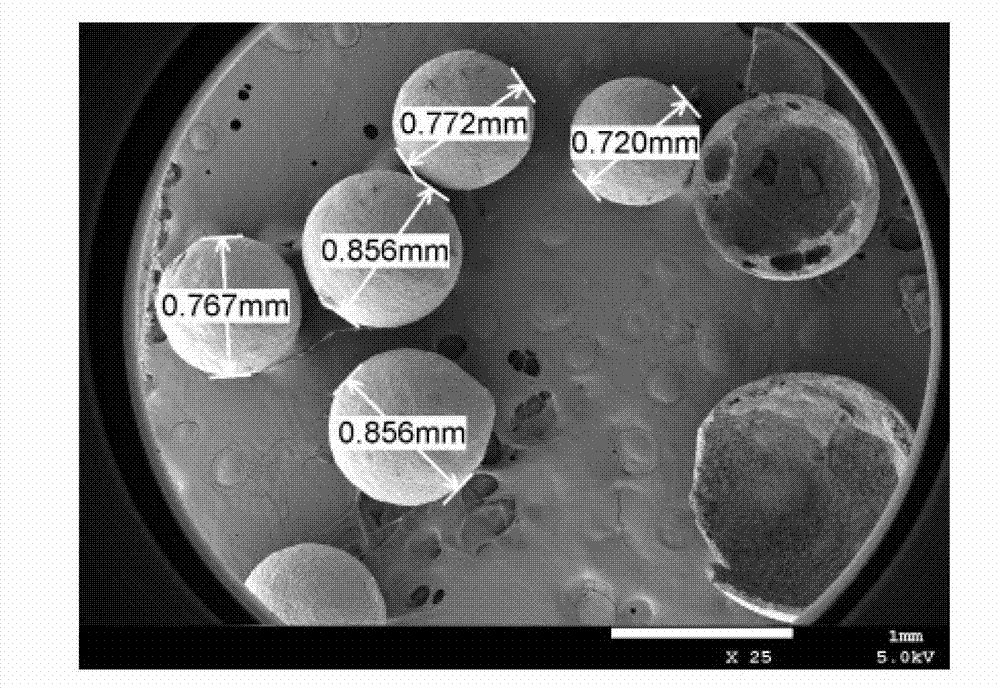

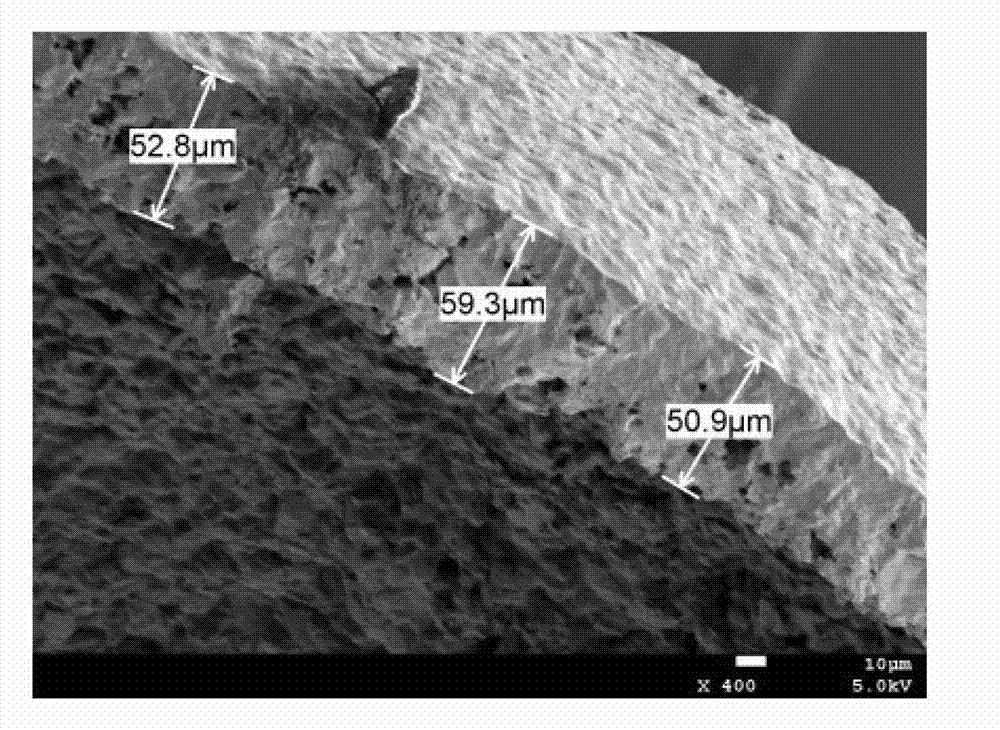

SiO2-Al2O3 hollow ceramic ball and preparation method thereof

A technology of sio2-al2o3 and ceramic balls, which is applied in the field of SiO2-Al2O3 hollow ceramic balls and their preparation, can solve the problems of uneven particle size distribution, high energy consumption, and high ratio of solid balls, and achieve low energy consumption and high sintering temperature Moderate, simple and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

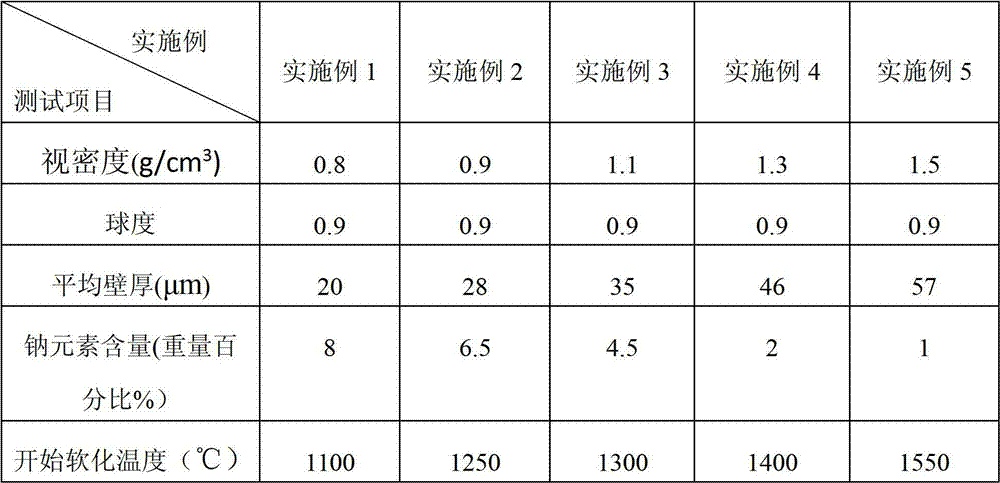

Embodiment 1

[0025] In 25 parts of water glass, add 3 parts of α-Al in sequence 2 o 3 , 1 part of urea, stirred at high speed for 30 minutes until the raw materials are evenly distributed, granulated by spray drying, the pre-calcination temperature is 300-400 ° C, and the holding time is 1 hour, then pickling to remove sodium, pickling solution H + The concentration is 1 mole / liter, the pickling time is 1 hour, and finally sintered at a high temperature of 1300 ° C, and kept for 2 hours to obtain hollow ceramic balls.

Embodiment 2

[0027] In 25 parts of water glass, add 4 parts of pyrophyllite and 1 part of urea in turn, stir at high speed for 30 minutes until the raw materials are evenly distributed, and granulate by spray drying. Wash out sodium, pickling solution H + The concentration is 1 mol / liter, the pickling time is 2 hours, and finally sintered at a high temperature of 1350°C and kept for 2 hours to obtain hollow ceramic balls.

Embodiment 3

[0029] In 25 parts of water glass, sequentially add 4 parts of α-Al 2 o 3 , 1 part of urea, stirred at high speed for 30 minutes until the raw materials are evenly distributed, granulated by spray drying, the pre-calcination temperature is 500-700 ° C, and the holding time is 1 hour, then pickling to remove sodium, pickling solution H + The concentration is 1 mol / liter, the pickling time is 3 hours, and finally sintered at a high temperature of 1400°C and kept for 2 hours to obtain hollow ceramic balls.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com