Method for roasting ultralow-carbon lime in rotary kiln and lime product produced by same

A technology of rotary kiln and limestone, which is applied in the field of ultra-low carbon lime roasting in rotary kiln and lime products produced by it, can solve problems such as inability to meet quality requirements, and achieve the effects of low production cost, good moisture resistance and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

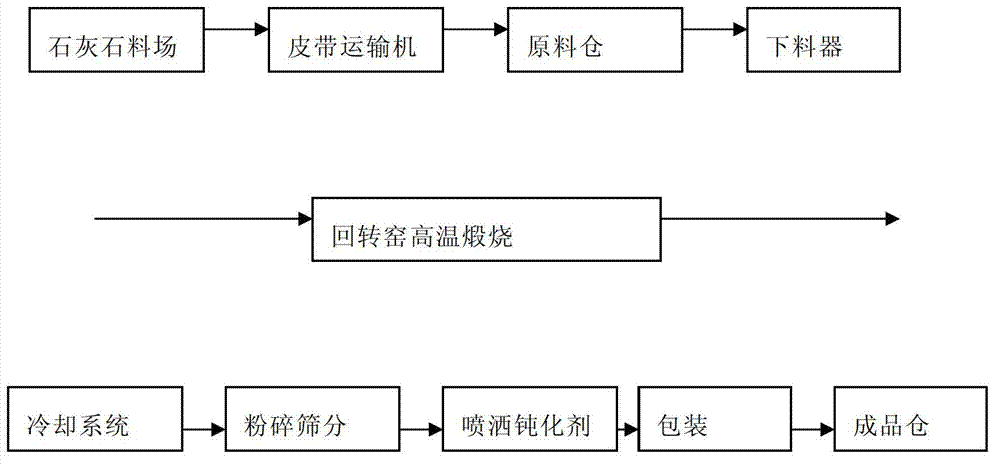

Method used

Image

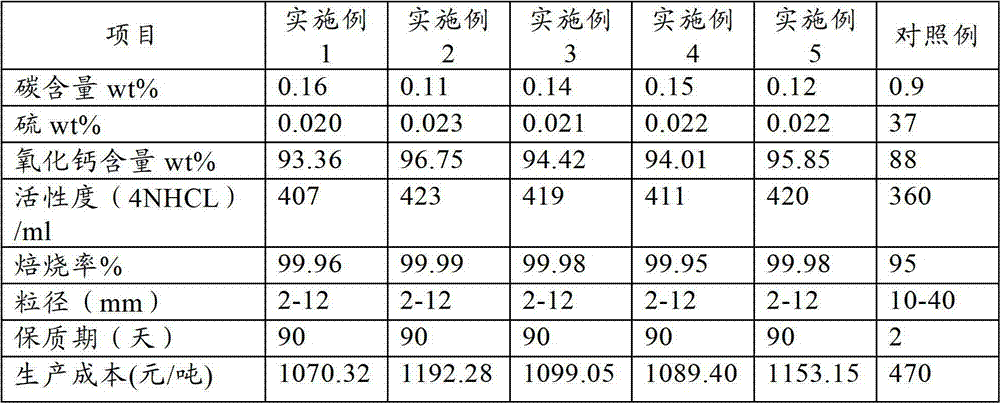

Examples

Embodiment 1

[0047] Before the experiment, 20-40mm limestone was prepared, the particle size exceeded the upper and lower limit by no more than 3%, the S content of the raw material was 0.02wt%, and the CaO content was 52wt%.

[0048] The main parameters of rotary kiln calcination are controlled according to the following standards: speed 0.73 rpm, calcination temperature 1010°C, kiln head temperature 650°C, secondary air volume 53000Nm 3 / hour, the coal injection rate is 6800 kg / hour, and the fuel injection rate is 6L / min.

[0049] Calcined for 1.5 hours, cooled to 100°C, crushed with a PC300×400mm hammer crusher to obtain lime with a particle size of 0-15mm, and passed through a linear vibrating screen with an upper layer of 12mm and a lower layer of 5mm for sieving to obtain a particle size of 2- 12mm of lime, adding calcium chloride for passivation, to obtain lime products.

Embodiment 2

[0051] Before the experiment, 20-40mm limestone was prepared, the particle size exceeded the upper and lower limit by no more than 3%, the S content of the raw material was 0.02wt%, and the CaO content was 52wt%.

[0052] The main parameters of rotary kiln calcination are controlled according to the following standards: speed 0.8 rpm, calcination temperature 1050°C, kiln head temperature 920°C, secondary air volume 55000Nm 3 / hour, the coal injection rate is 7200 kg / hour, and the fuel injection rate is 10L / min.

[0053] Calcined for 2.5 hours, cooled to 150°C, crushed with a PC300×400mm hammer crusher to obtain lime with a particle size of 0-15mm, passed through a linear vibrating screen with an aperture of 12mm in the upper layer and 5mm in the lower layer, and sieved to obtain a particle size of 2- 12mm of lime, adding calcium chloride for passivation, to obtain lime products.

Embodiment 3

[0055] Before the experiment, 20-40mm limestone was prepared, the particle size exceeded the upper and lower limit by no more than 3%, the S content of the raw material was 0.02wt%, and the CaO content was 52wt%.

[0056] The main parameters of rotary kiln calcination are controlled according to the following standards: speed 0.76 rpm, calcination temperature 1030°C, kiln head temperature 785°C, secondary air volume 54000Nm3 / hour, coal volume 7000kg / hour, fuel injection volume 8L / min.

[0057] After calcination for 2 hours, after cooling to 120°C, use a PC300×400mm hammer crusher to crush lime with a particle size of 0-15mm, and pass through a linear vibrating screen with an upper layer of 12mm and a lower layer of 5mm for sieving to obtain a particle size of 2- 12mm of lime, adding calcium chloride for passivation, to obtain lime products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com