Preparation method of graphene-based ferroferric oxide nano-composite material

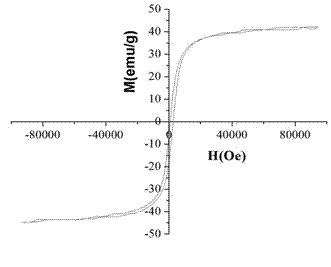

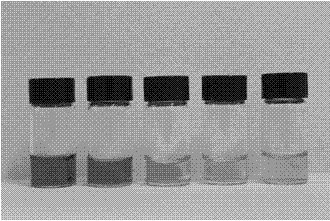

An alkenyl triiron tetroxide and nano-composite material technology, applied in the directions of graphene, iron oxide/iron hydroxide, nano-carbon, etc., can solve the problem that the loading rate cannot be effectively controlled, the particle size distribution of magnetic nanoparticles is uneven, The problem of low saturation magnetization of composite materials can achieve the effect of good dye and heavy metal ion adsorption capacity, large specific surface area, and high saturation magnetic induction intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 0.01 mol of ferric chloride hexahydrate into 100 mL of deionized water, stir and dissolve completely

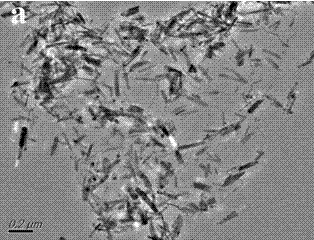

[0034] 10 mg of graphite oxide was added to the aqueous solution of ferric chloride hexahydrate. After ultrasonication for 1 hour, 2.705 g of hydrazine hydrate was added dropwise to the reaction system. Finally, the mixed solution was reacted at 100 °C for 2 hours under stirring. The hydrolyzed product is centrifugally washed several times with deionized water, and after being vacuum-dried, a graphene-based ferric oxide nanocomposite material is obtained.

Embodiment 2

[0036] Add 0.05 mol of ferric nitrate into 100 mL of deionized water, stir and dissolve completely, and add 15 mg of oxygen

[0037] Graphite was added to the aqueous solution of ferric nitrate. After ultrasonication for 1 hour, 12.10 g of hydrazine hydrate was added dropwise to the reaction system. Finally, the mixed solution was reacted at 60 °C for 4 hours under stirring, and the hydrolyzate was centrifuged with deionized water. After cleaning several times and vacuum drying, a graphene-based ferric oxide nanocomposite material is obtained.

Embodiment 3

[0039] Add 0.03 mol of ferric sulfate into 100 mL of deionized water, stir and dissolve 20 mg

[0040] Graphite oxide was added to the aqueous solution of ferric sulfate. After ultrasonication for 1 hour, 12.00 g of hydrazine hydrate was added dropwise to the reaction system. Finally, the mixed solution was reacted at 150 °C for 1 hour under stirring, and the hydrolyzed product was washed with deionized water. After several times of centrifugal cleaning and vacuum drying, a graphene-based ferric oxide nanocomposite material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com