Porous carbon/sulfur composite material, its preparation method and application

A technology of porous carbon materials and composite materials, which is applied to porous carbon/sulfur composite materials and the fields of their preparation and application, can solve the problems of poor high rate performance and cycle performance, poor experimental repeatability, and complicated operation of sulfur-carbon composite materials. , to achieve the effect of suitable for large-scale production, easy availability of raw materials, and high degree of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, preparation porous carbon / sulfur composite material

[0030] Weigh the mixture of alginic acid and sodium hydroxide, the mass ratio of sodium hydroxide is 50%, add water, stir and mix evenly. The moisture was evaporated, and the mixture was heated at 700°C for 8h under a nitrogen atmosphere. After the reaction is complete, add 50% sulfuric acid aqueous solution, stir at room temperature for 24 hours, centrifuge and wash with water several times until neutral. Vacuum drying at 80°C yielded porous carbon. The mixture of porous carbon and sulfur powder was weighed, and the mass content of sulfur was 50%. After mixing evenly, it was heated at 120°C for 48h under an air atmosphere to obtain a porous carbon / sulfur composite material.

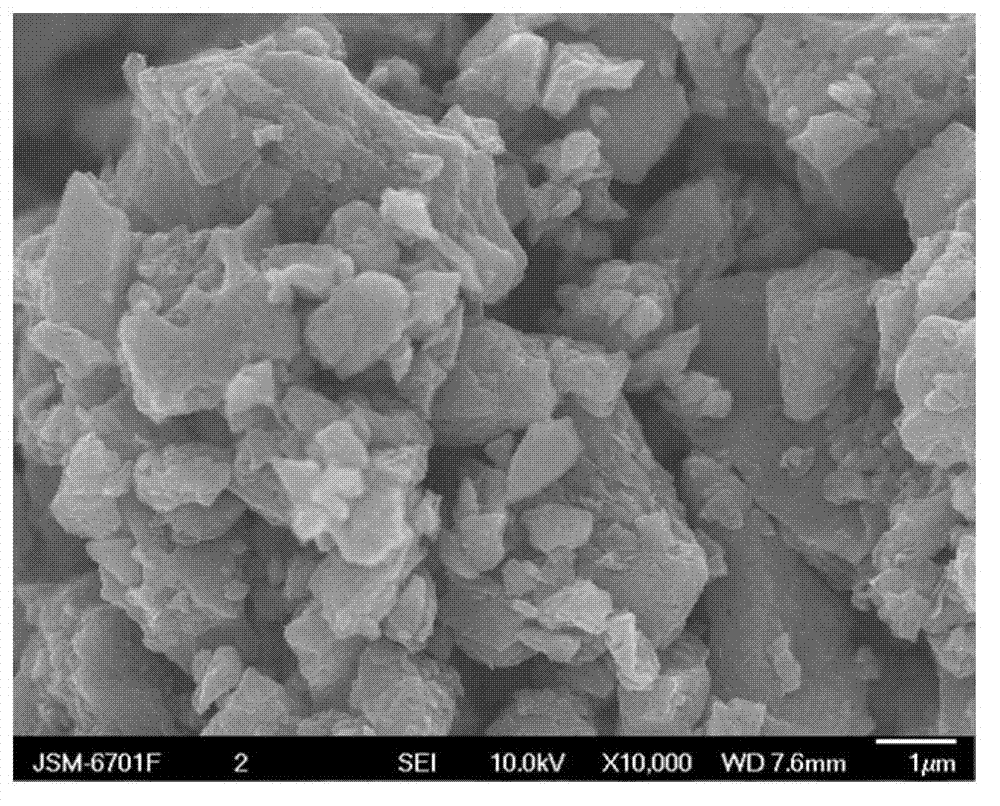

[0031] The scanning electron micrograph of the porous carbon / sulfur composite material prepared in this embodiment is as follows figure 1 shown.

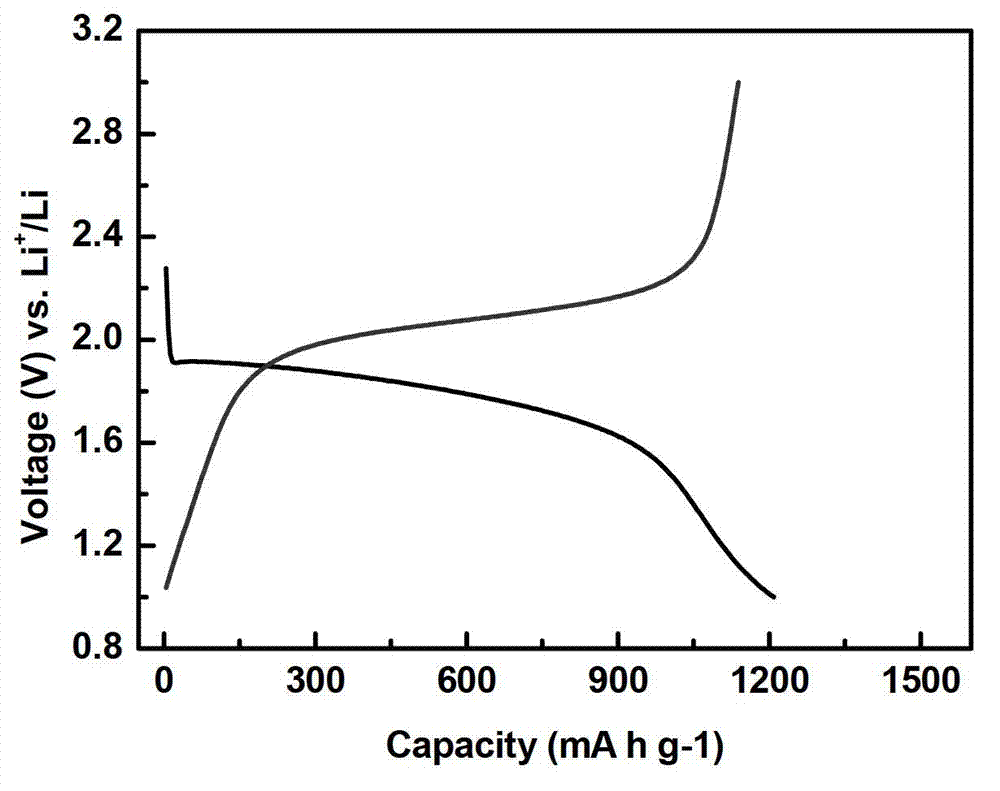

[0032] Electrochemical performance characterization of porous carbon / sulfur com...

Embodiment 2

[0036] Embodiment 2, preparation porous carbon / sulfur composite material

[0037] Weigh the mixture of alginic acid and sodium hydroxide, the mass ratio of sodium hydroxide is 30%, add water, stir and mix evenly. The moisture was evaporated, and the mixture was heated at 850°C for 6h under a nitrogen atmosphere. After the reaction is complete, add 30% sulfuric acid aqueous solution, stir at room temperature for 36 hours, centrifuge and wash with water several times until neutral. Vacuum drying at 100°C yielded porous carbon. Weigh the mixture of porous carbon and sulfur powder, the mass content of sulfur is 45%, after mixing evenly, heat at 250°C for 10h under air atmosphere to obtain porous carbon / sulfur composite material.

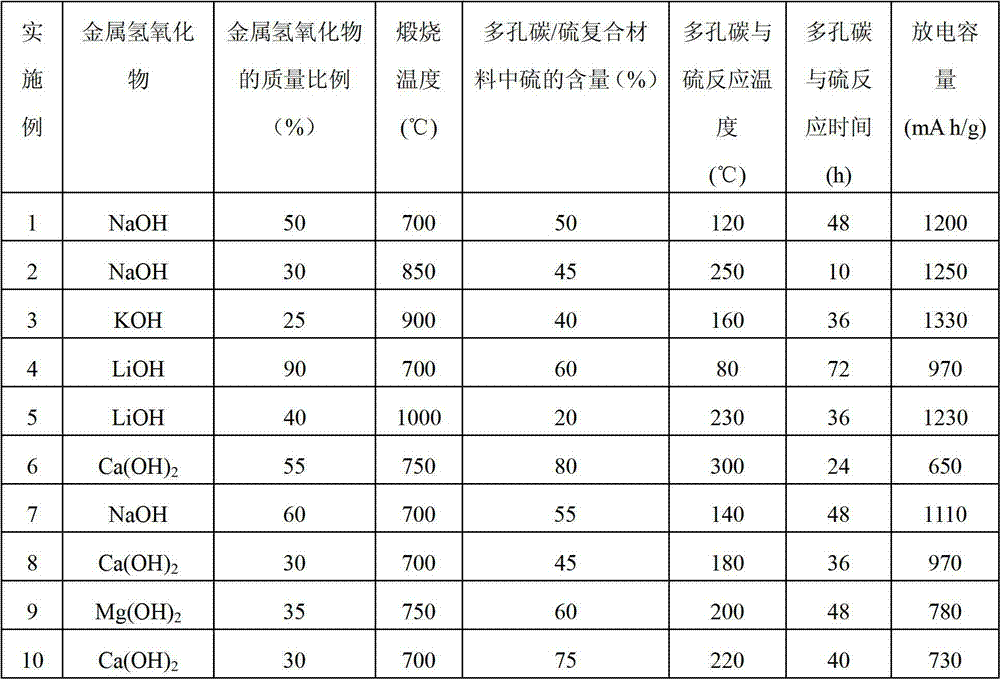

[0038] The electrochemical performance of the obtained porous carbon / sulfur composite material was tested according to the method in Example 1, and the key experimental conditions and simulated battery test results for preparing the porous carbon / sulfu...

Embodiment 3

[0039] Embodiment 3, preparation porous carbon / sulfur composite material

[0040]Weigh the mixture of alginic acid and potassium hydroxide, the mass ratio of potassium hydroxide is 25%, add water, stir and mix evenly. The moisture was evaporated, and the mixture was heated at 900°C for 5h in an argon atmosphere. After the reaction is complete, add 20% aqueous nitric acid solution, stir at room temperature for 24 hours, centrifuge and wash with water several times until neutral. Drying at 150°C in an argon atmosphere yielded porous carbon. The mixture of porous carbon and sulfur powder was weighed, and the mass content of sulfur was 40%. After mixing evenly, it was heated at 160° C. for 36 h under an air atmosphere to obtain a porous carbon / sulfur composite material.

[0041] The electrochemical performance of the obtained porous carbon / sulfur composite material was tested according to the method in Example 1, and the key experimental conditions and simulated battery test res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com