Drying unit of nitrogen-source heat pump

A technology of drying unit and source heat pump, which is applied in the direction of local stirring dryer, static material dryer, drying machine, etc., can solve the problems of damaging nutrients, high energy consumption, and reducing material quality, so as to prevent oxidation and consume Low energy, high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further elaborated below in conjunction with specific embodiments.

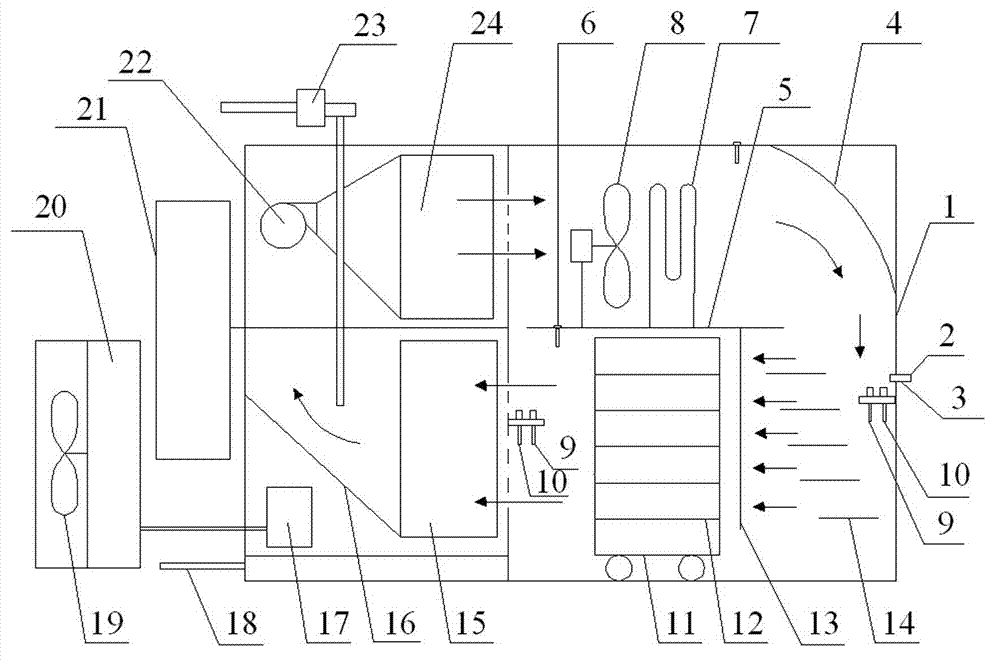

[0041] Such as figure 1 As shown, a nitrogen source heat pump drying unit includes a drying box, a control system 21 and an outdoor condenser 20. The drying box includes a box body 1 and a heat pump room and a drying room arranged in the box body. A small pusher is placed in the drying room. The car 11 and the material tray 12 are characterized in that a horizontal baffle 5 is provided on the side close to the heat pump room in the drying chamber, and the baffle 5 divides the drying chamber into upper and lower air passages, and the material tray 12 is arranged in the lower part On the trolley 11 in the air passage, the upper and lower parts of the heat pump chamber are respectively provided with vents connected with the upper and lower air passages of the drying chamber;

[0042]A condenser 24 is installed on the upper part of the heat pump chamber, and an evaporator 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com