A kind of preparation method of sodium bismuth titanate-lead titanate piezoelectric single crystal

A lead titanate piezoelectric, bismuth sodium titanate technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., to achieve the effects of excellent piezoelectric performance, wide operating temperature range, and good electric field stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

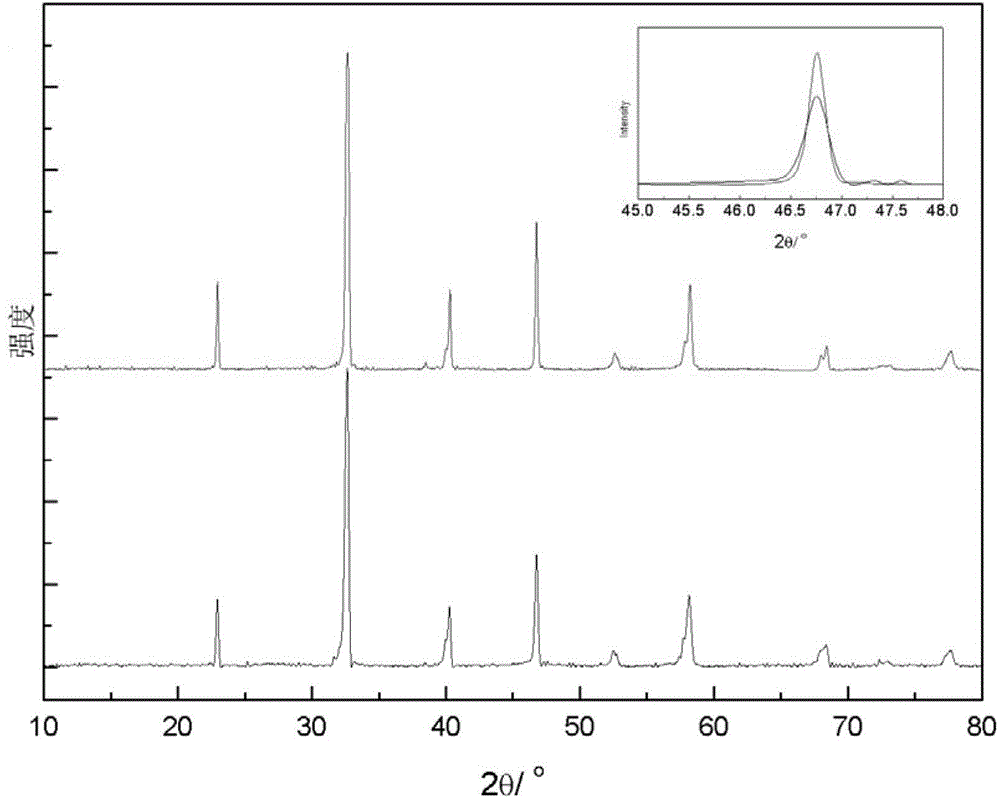

Embodiment 1

[0034] According to the general formula 0.91Na 0.5 Bi 0.5 TiO 3 -0.09PbTiO 3 Accurately weigh the raw materials of sodium carbonate, bismuth oxide, titanium dioxide and lead oxide powders with a stoichiometric purity greater than 99.99% and fully dry, and ball mill them for 24 hours to mix them evenly; then put them into a covered platinum crucible, Sintering at 1000°C for 6 hours; the sintered product is crushed, finely ground, sieved, and cold isostatically pressed into blocks as the starting material for single crystal growth;

[0035]A single-layer Ф20mm×200mm platinum crucible is selected as the growth crucible, and a -oriented NBT-PT single crystal with a size of Ф19.5mm×50mm is used as the seed crystal; the seed crystal and the starting material for single crystal growth are loaded and sealed Crucible, and then placed in the growth furnace (the present invention has no strict restrictions on the growth equipment, as long as the growth furnace device with temperature ...

Embodiment 2

[0042] The difference between this embodiment and embodiment 1 is only:

[0043] The operation of preparing the starting material for single crystal growth is as follows: according to the general formula 0.99Na 0.5 Bi 0.5 TiO 3 -0.01PbTiO 3 Accurately weigh the raw materials of sodium carbonate, bismuth oxide, titanium dioxide and lead oxide powders with a stoichiometric purity greater than 99.99% and fully dry, and ball mill them for 24 hours to make them evenly mixed; After isostatic pressing into blocks, it is used as the starting material for single crystal growth.

[0044] The rest of the content is the same as described in Example 1.

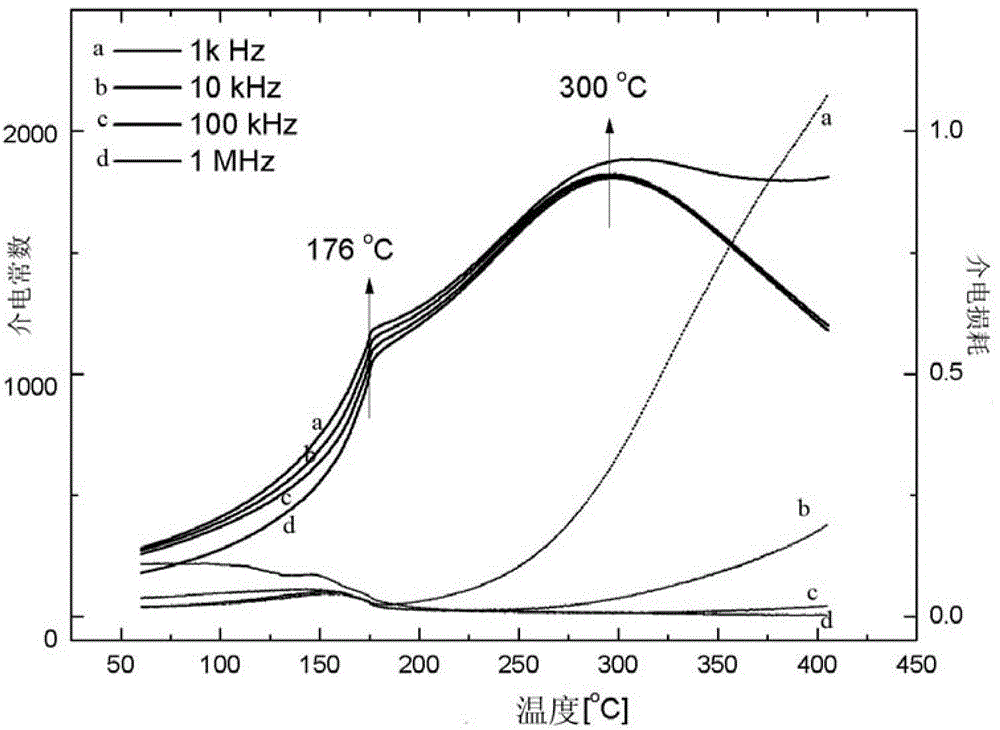

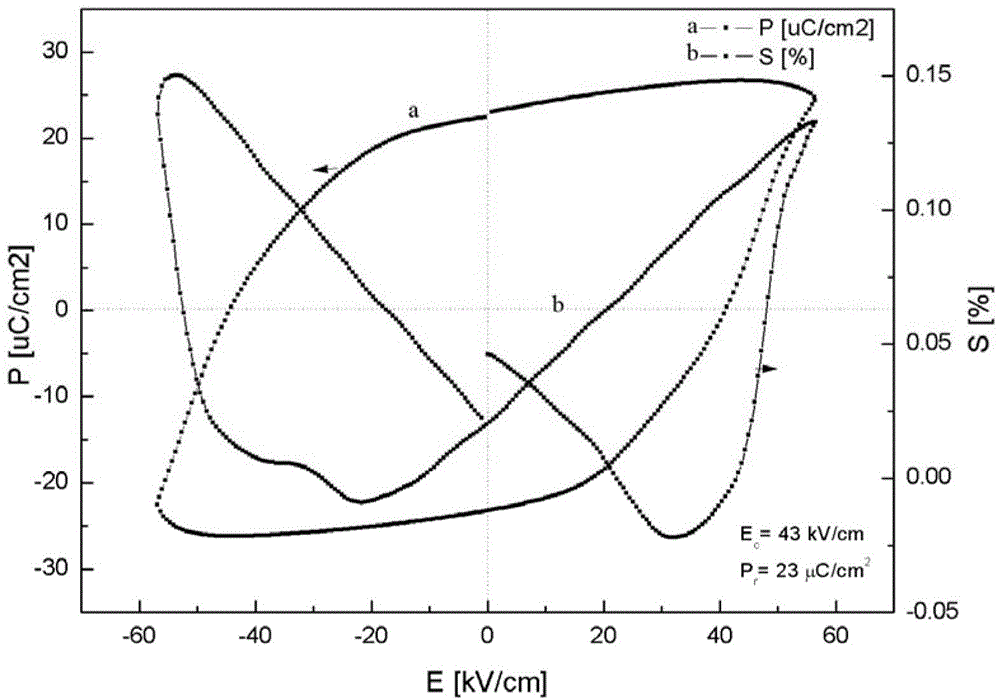

[0045] The experimental results show that in this example, the crystal ingot size can reach Ф20mm×70mm, the Curie temperature is about 300°C, the depolarization temperature is about 176°C, and the piezoelectric constant d 33 Up to 280pC / N, electromechanical coupling coefficient k t Sodium bismuth titanate-lead titanate piezoelectric ...

Embodiment 3

[0047] The difference between this embodiment and embodiment 1 is only:

[0048] The operation of preparing the starting material for single crystal growth is as follows:

[0049] 1) According to the chemical formula Na 0.5 Bi 0.5 TiO 3 Accurately weigh sodium carbonate and bismuth oxide with a stoichiometric ratio of purity greater than 99.99%, ball mill for 24 hours to mix evenly, and then perform a solid-state reaction at 1100°C for 4 hours to sinter into NBT polycrystalline material;

[0050] 2) According to the chemical formula PbTiO 3 Accurately weigh titanium dioxide and lead oxide with a stoichiometric ratio of purity greater than 99.99%, ball mill for 24 hours to mix evenly, and then conduct a solid-state reaction at 1100°C for 4 hours to sinter into a PT polycrystalline material;

[0051] 3) According to the general formula 0.86Na 0.5 Bi 0.5 TiO 3 -0.14PbTiO 3 Accurately weigh the stoichiometric ratio of NBT and PT polycrystalline materials, ball mill for 24 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com