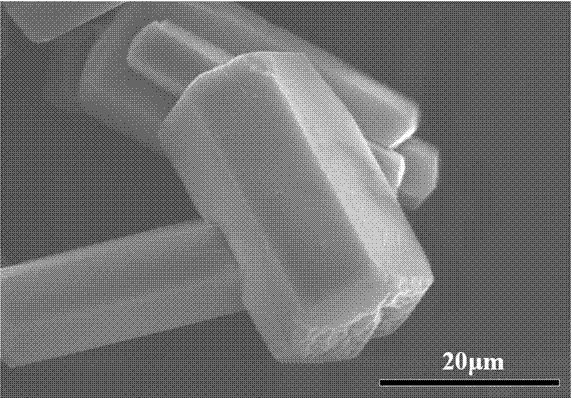

Biomedical alpha-Ca (HPO4) x (SO4)1-x*1/2H2O solid solution particle and preparation method thereof

A technology of HPO42-, 2H2O, applied in chemical instruments and methods, prostheses, medical science, etc., to achieve the effect of simple operation, easy industrialization, improvement of injection performance and biodegradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

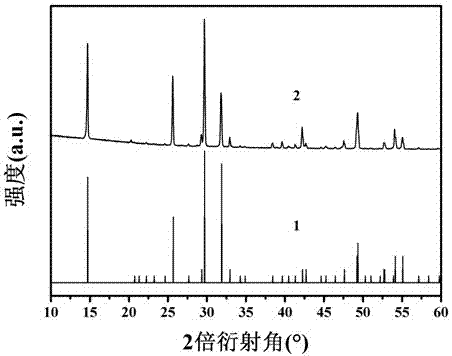

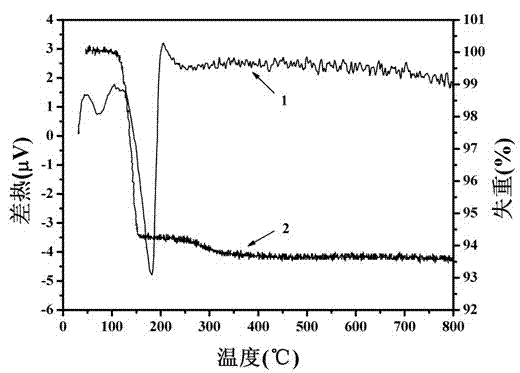

Embodiment 1

[0022] 1) Add CaCl 2 and K 2 SO 4 Dissolved in deionized water, respectively prepared into solutions, mixed at room temperature according to the molar ratio of Ca / S of 1:1, the reaction was carried out under constant stirring, the reaction temperature was room temperature, and the reaction time was 2 hours. After the reaction, use Filter 3 times with deionized water, once with alcohol, and then dry at 60°C to obtain CaSO 4 2H 2 O;

[0023] 2) Dissolve 0.4g of citric acid monohydrate in 400ml of deionized water to make an electrolyte solution;

[0024] 3) 10g of CaSO obtained in step 1) 4 2H 2 0 and the electrolyte solution prepared in step 2) are mixed to obtain a suspension;

[0025] 4) Add 1g of CaHPO 4 2H 2 O and the suspension prepared in step 3) are stirred and mixed, then put into the reaction kettle, so that the molar ratio of P / S in the mixed solution is 0.1, and the reaction is carried out under the hydrothermal condition of 130°C, and the reaction time is 10...

Embodiment 2

[0027] 1) CaNO 3 and K 2 SO 4 Dissolved in deionized water, respectively prepared into solutions, mixed at room temperature according to the molar ratio of Ca / S of 1:1, the reaction was carried out under constant stirring, the reaction temperature was room temperature, and the reaction time was 2 hours. After the reaction, use Filter 3 times with deionized water, once with alcohol, and then dry at 60°C to obtain CaSO 4 2H 2 O;

[0028] 2) Dissolve 0.4g of citric acid monohydrate in 400ml of deionized water to make an electrolyte solution;

[0029] 3) 10g of CaSO obtained in step 1) 4 2H 2 0 and the electrolyte solution prepared in step 2) are mixed to obtain a suspension;

[0030] 4) Add 4.16g of Na 2 HPO 4 12H 2 O and the suspension prepared in step 3) are stirred and mixed, then put into the reaction kettle, so that the molar ratio of P / S in the mixed solution is 0.2, and the reaction is carried out under the hydrothermal condition of 140°C, and the reaction time i...

Embodiment 3

[0036] 1) Add CaCl 2 and Na 2 SO 4 Dissolved in deionized water, respectively prepared into solutions, mixed at room temperature according to the molar ratio of Ca / S of 1:1, the reaction was carried out under constant stirring, the reaction temperature was room temperature, and the reaction time was 2 hours. After the reaction, use Filter 3 times with deionized water, once with alcohol, and then dry at 60°C to obtain CaSO 4 2H 2 O;

[0037] 2) Dissolve 0.4g of citric acid monohydrate in 400ml of deionized water to make an electrolyte solution;

[0038] 3) 10g of CaSO obtained in step 1) 4 2H 2 0 and the electrolyte solution prepared in step 2) are mixed to obtain a suspension;

[0039] 4) Add 2.37g of KH 2 PO 4 Stir and mix the suspension prepared in step 3) and put it into the reaction kettle so that the molar ratio of P / S in the mixture is 0.3. The reaction is carried out under hydrothermal conditions at 150°C, and the reaction time is 6 hours. The reacted sample w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com