A kind of high-strength self-toughening building cement and its preparation method

A construction cement and self-toughening technology, applied in the field of construction materials, can solve the problems of stimulating cement gel strength, easy shrinkage of high-strength concrete, and easy early cementation, etc., to improve easy shrinkage, improve pumping effect, and improve uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

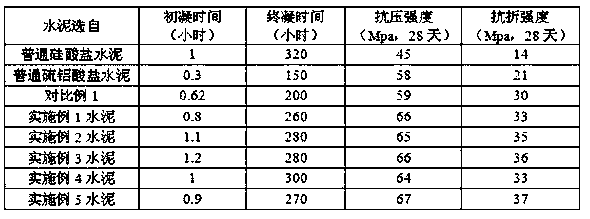

Examples

Embodiment 1

[0031] A kind of high-strength self-toughening building cement, raw materials are calculated by weight, comprising:

[0032] 50 parts of sulphoaluminate cement

[0033] 50 parts of aluminate cement

[0034] Chlorinated paraffin 5 parts

[0035] EVA wax 2 parts

[0036] 30 parts of fly ash

[0037] Tailings 30 parts

[0038] Phosphorus slag 30 parts

[0039] Steel slag 10 parts

[0040] 5 parts wood fiber

[0041] The wood fibers are soaked in calcium chloride solution and dried to obtain wood fibers adsorbing calcium chloride;

[0042] A preparation of high-strength self-toughening building cement, comprising the following steps:

[0043] (1) Use a kneader to disperse and grind sulfoaluminate cement, ferroaluminate cement, chlorinated paraffin, and EVA wax evenly, at a temperature of 100°C, and mix for 2 hours to obtain sulfoaluminum evenly wrapped with chlorinated paraffin and EVA wax Salt cement powder;

[0044] (2) Loosely disperse the wood fibers adsorbed by calc...

Embodiment 2

[0047] A high-strength self-toughening building cement, raw materials by weight, comprising:

[0048] 60 parts of sulphoaluminate cement

[0049] 60 parts of aluminate cement

[0050] Chlorinated paraffin 8 parts

[0051] EVA wax 2 parts

[0052] Fly ash 15 parts

[0053] Tailings 10 parts

[0054] Phosphorus slag 10 parts

[0055] Steel slag 30 parts

[0056] 10 parts wood fiber;

[0057] The wood fibers are soaked in calcium chloride solution and dried to obtain wood fibers adsorbing calcium chloride;

[0058] A preparation of high-strength self-toughening building cement, comprising the following steps:

[0059] (1) Use a heatable agitator to disperse and grind iron-aluminate cement, iron-aluminate cement, chlorinated paraffin, and EVA wax evenly, at a temperature of 100°C, and mix for 24 hours to obtain evenly wrapped chlorinated paraffin and EVA wax Sulphoaluminate cement, ferroaluminate cement powder;

[0060](2) Loosely disperse the wood fibers adsorbed by cal...

Embodiment 3

[0063] A high-strength self-toughening building cement, raw materials by weight, comprising:

[0064] 70 parts of sulphoaluminate cement

[0065] 50 parts of aluminate cement

[0066] Chlorinated paraffin 5 parts

[0067] EVA wax 3 parts

[0068] Tailings 5 parts

[0069] Phosphorus slag 3 parts

[0070] Steel slag 15 parts

[0071] 16 parts of wood fiber;

[0072] The wood fibers are soaked in calcium chloride solution and dried to obtain wood fibers adsorbing calcium chloride;

[0073] A preparation of high-strength self-toughening building cement, comprising the following steps:

[0074] (1) Use a kneader to disperse and grind sulfoaluminate cement, ferroaluminate cement, chlorinated paraffin, and EVA wax evenly, at a temperature of 160°C, and mix for 12 hours to obtain sulfoaluminum evenly wrapped with chlorinated paraffin and EVA wax Salt cement, aluminate cement powder;

[0075] (2) Loosely disperse the wood fibers adsorbed by calcium chloride to obtain loose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com