Floating selection method of nonferrous metal mineral powder

A technology for non-ferrous metals and ore powder, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of high steel consumption, large water consumption, and high power consumption of ball mills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

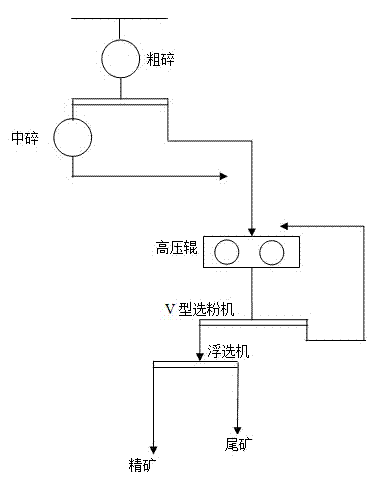

Embodiment 1

[0020] For a molybdenum ore in Henan with a raw ore Mo grade of 0.13%, it is roughly crushed to 250mm by a crusher, screened, and crushed to less than 60mm, and fed into a high-pressure roller mill. The high-pressure roller mill controls the projection pressure to 3.5MPa~5.5MPa , the fan speed is controlled at 45Hz, the rotor powder separator speed is 35Hz, the cyclone product -0.074mm accounted for 60% of the product is fed into the slurry mixer, and then flotation is carried out, after a rough selection, three times of sweeping, and five times of selection A concentrate with a Mo grade of 45% and a Mo grade tailings with a Mo grade of 0.012% are obtained. The bottom coarse material of the V-type separator is returned to the high-pressure roller mill through the hoist for regrinding to form a closed circuit.

Embodiment 2

[0022] For a copper mine in Inner Mongolia with a raw ore grade of 1.5% Cu, it is roughly crushed by a crusher to 200mm, screened, and crushed to less than 40mm, and fed into a high-pressure roller mill. The high-pressure roller mill controls the projection pressure to 3.5MPa~5.5MPa , control the speed of the fan to 40Hz, the speed of the rotor powder separator to 45Hz, and the cyclone product -0.074mm accounts for 80% of the product to be added to the slurry mixer, followed by flotation, after a rough selection, two sweeps, and three fines The concentrated ore with a Cu grade of 20% and the tailings with a Cu grade of 0.11% are obtained. The coarse material at the bottom of the V-type separator is returned to the high-pressure roller mill through the elevator to form a closed circuit.

Embodiment 3

[0024] For a copper mine in Tibet with a raw ore grade of 1.5% Cu, it is roughly crushed by a crusher to 300mm, screened, and crushed to less than 45mm, and fed into a high-pressure roller mill. The high-pressure roller mill controls the projection pressure to 3.5MPa~5.5MPa , control the speed of the fan at 45Hz, the speed of the rotor powder separator at 50Hz, and the cyclone product -0.074mm accounts for 90% of the product to be added to the slurry mixer, and then flotation, after a rough selection, two sweeps, and three fines The concentrated ore with a Cu grade of 18.7% and the tailings with a Cu grade of 0.07% are obtained. The coarse material at the bottom of the V-type separator is returned to the high-pressure roller mill through the elevator to form a closed circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com