System and method for monitoring oil consumption of engineering vehicle and engine

A monitoring system and engine technology, which is applied in measuring devices, relative volume flow measurement, liquid/fluid solid measurement, etc., can solve the problem of high sensor installation requirements, and achieve the effect of single type of sensor and simple arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict. The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

[0029] On the one hand, the present invention provides an engine fuel consumption monitoring system, which is combined with the following Figure 1 to Figure 5 Preferred embodiments thereof will be described in detail.

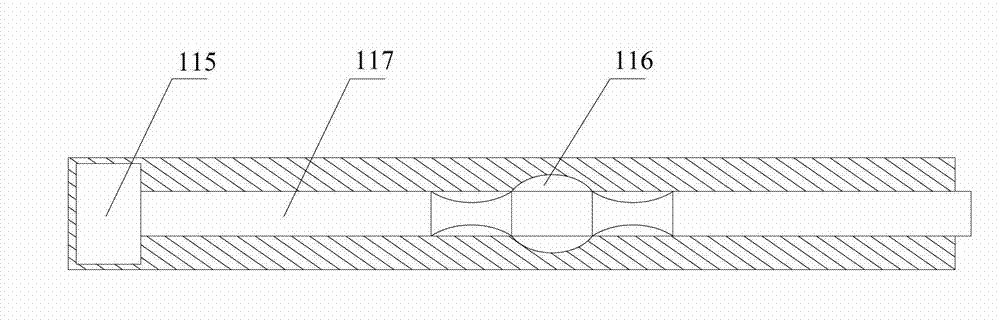

[0030] see figure 1 It can be known from the related art that the engine 3 drives the oil pump 2 to supply oil to the hydraulic pipeline 1 connected to the oil outlet of the oil pump 2 . Wherein, a hydraulic control valve 11 is installed on the hydraulic pipeline 1, and the inlet pipeline 111 of the execution oil circuit of the hydraulic control valve 11 is connected with the oil outlet pipeline 21 of the oil pump 2, and the outlet pipe of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com