Method for separating and recycling positive and negative electrode mixed powder of waste ternary lithium ion battery

A lithium-ion battery and mixed powder technology, which is applied in battery recycling, waste collector recycling, solid separation and other directions, can solve problems such as unfavorable large-scale industrial operation, small positive and negative mixed powder particles, large consumption of leaching acid, Alkali preparation and other problems can reduce production dust and waste water, reduce the amount of chemicals added, and reduce material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

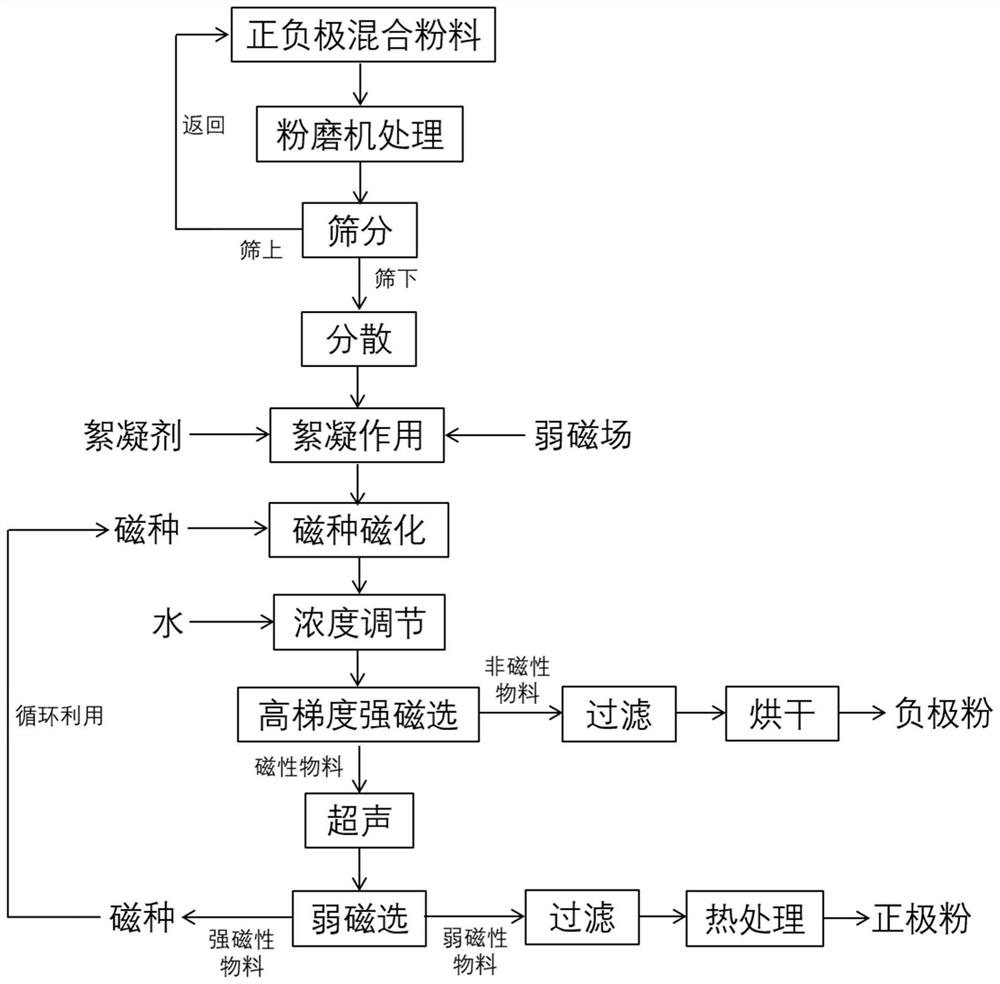

[0056] S1 First, the positive and negative mixed powder of waste ternary lithium batteries containing Ni, Co, and Mn is treated with a pulverizer and then sieved, and the powder with an oversized particle size on the sieve is returned to the pulverizer for further processing, and the granules are obtained under the sieve Positive and negative electrode mixed powder with a diameter ranging from 200 mesh to 300 mesh.

[0057] S2 disperses the positive and negative electrode mixed powder between 200 mesh and 300 mesh under the sieve of step S1 in water under the mechanical stirring condition of 1000r / min at a speed of 1000r / min, the stirring time is 20min, and the pH of the slurry is controlled to be 8 to obtain a solid content of 10% Slurry I.

[0058] S3 Under the conditions of a stirring speed of 500r / min and a magnetic field strength of 0.1T, the flocculant ammonium polyacrylate with a mass concentration of 0.1% prepared within a week was added to the slurry I for bridging fl...

Embodiment 2

[0066] S1 First, the positive and negative mixed powder of waste ternary lithium batteries containing Ni, Co, Mn, and Fe is treated with a pulverizer and then sieved, and the powder with too large particle size on the sieve is returned to the pulverizer to continue processing, The positive and negative electrode mixed powder with a particle size ranging from 300 mesh to 400 mesh is obtained.

[0067] S2 Disperse the positive and negative electrode mixed powder between 300 mesh and 400 mesh under the sieve of step S1 in water under the condition of mechanical stirring at 1300r / min, stirring for 30min, and controlling the pH of the slurry to 11 to obtain the solid content 20% slurry I.

[0068] S3 Under the conditions of a stirring speed of 700r / min and a magnetic field strength of 0.5T, a flocculant non-ionic polyacrylamide with a mass concentration of 0.2% prepared within a week was added to the slurry I for bridging flocculation. The non-ionic polyacrylamide solution account...

Embodiment 3

[0076] S1 First, the positive and negative mixed powder of waste ternary lithium batteries containing Ni, Co, and Mn is treated with a pulverizer and then sieved, and the powder with an oversized particle size on the sieve is returned to the pulverizer for further processing, and the granules are obtained under the sieve Positive and negative electrode mixed powder with a diameter ranging from 100 mesh to 200 mesh.

[0077] S2 Disperse the positive and negative electrode mixed powder between 100 mesh and 200 mesh under the sieve in step S1 in water under the condition of mechanical stirring at 1100r / min, stirring for 15min, and controlling the pH of the slurry to 9 to obtain the solid content 15% slurry I.

[0078] S3 Under the conditions of a stirring speed of 800r / min and a magnetic field strength of 0.3T, a flocculant non-ionic polyacrylamide with a mass concentration of 0.1% prepared within a week was added to the slurry I to carry out bridging flocculation. The non-ionic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com