Solution and method for chemical machining of ei768 stainless steel workpiece

A technology for chemical processing and stainless steel, which is applied in the field of chemical processing solutions for эи768 stainless steel, which can solve the problems of difficult processing and easy generation of cutting stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

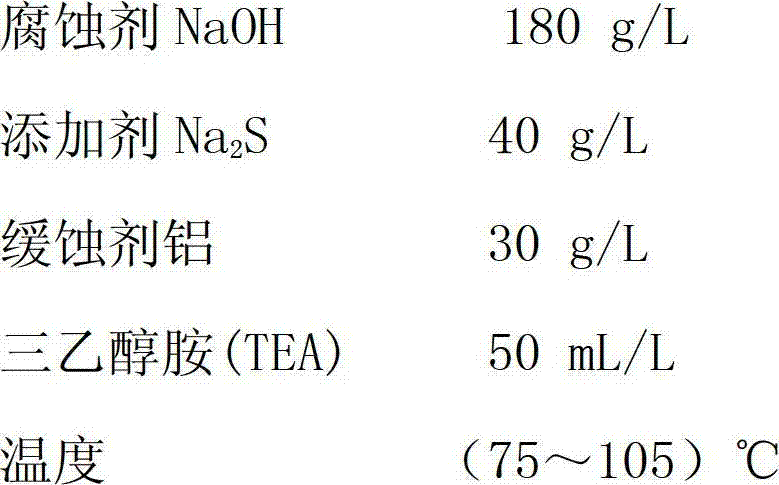

[0033] This embodiment is a solution for chemical processing of эи768 stainless steel workpieces. The solution includes hydrochloric acid, nitric acid, ferric chloride and water, wherein: hydrochloric acid is industrial pure grade, specific gravity d=1.18; nitric acid is industrial pure grade, specific gravity d=1.41; ferric chloride is industrial pure powder . The volume ratio of hydrochloric acid is 132ml / L, the volume ratio of nitric acid is 115ml / L, the weight volume ratio of ferric trichloride is 445g / L, all the other are water.

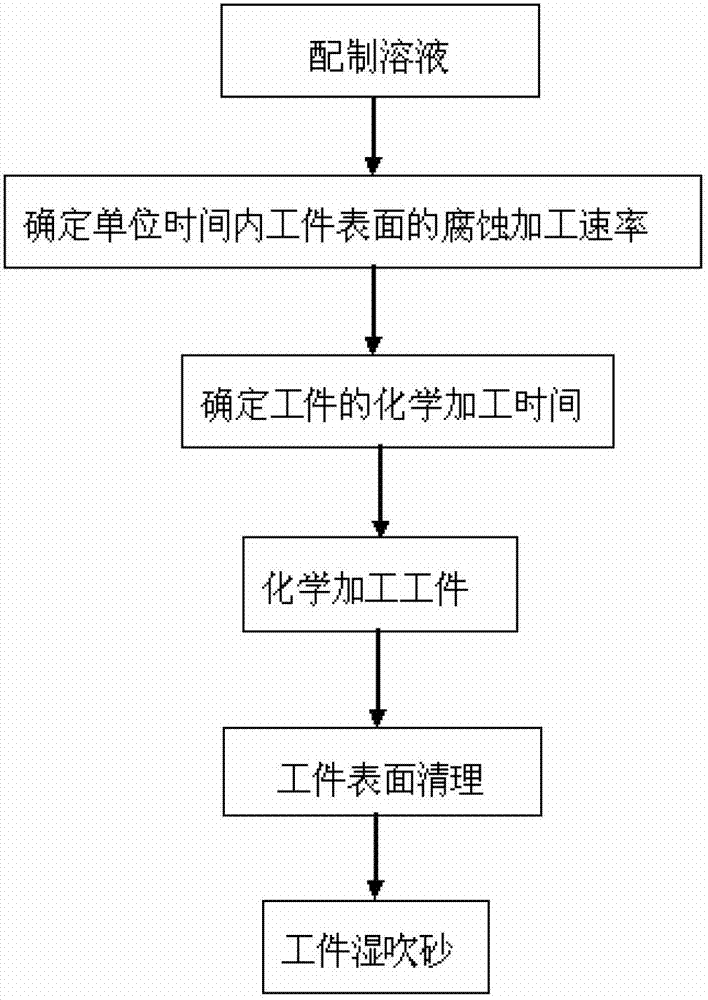

[0034] Present embodiment also proposes a kind of method utilizing the solution processing of described эи768 stainless steel workpiece chemical processing эи768 stainless steel plate-shaped workpiece, and its specific process is:

[0035] Step 1, prepare the solution. Prepare one liter of solution in proportion: wherein hydrochloric acid 132ml / L, nitric acid 115ml / L, iron trichloride 445g / L, balance is water. A prepared solution is obtained....

Embodiment 2

[0047] This embodiment is a solution for chemical processing of эи768 stainless steel workpieces. The solution includes hydrochloric acid, nitric acid, ferric chloride and water, wherein: hydrochloric acid is industrial pure grade, specific gravity d=1.18; nitric acid is industrial pure grade, specific gravity d=1.41; ferric chloride is industrial pure powder . The volume ratio of hydrochloric acid is 135ml / L, the volume ratio of nitric acid is 118ml / L, the weight-volume ratio of ferric chloride is 448g / L, and all the other are water.

[0048] Present embodiment also proposes a kind of method that utilizes the solution processing of described эи768 stainless steel workpiece chemical processing эи768 stainless steel annular workpiece, and its specific process is:

[0049] Step 1, prepare the solution. Prepare one liter of solution in proportion: wherein hydrochloric acid 135ml / L, nitric acid 118ml / L, iron trichloride 448g / L, and balance is water. A prepared solution is obtai...

Embodiment 3

[0061] This embodiment is a solution for chemical processing of эи768 stainless steel workpieces. The solution includes hydrochloric acid, nitric acid, ferric chloride and water, wherein: hydrochloric acid is industrial pure grade, specific gravity d=1.18; nitric acid is industrial pure grade, specific gravity d=1.41; ferric chloride is industrial pure powder . The volume ratio of hydrochloric acid is 138ml / L, the volume ratio of nitric acid is 121ml / L, the weight-volume ratio of ferric chloride is 450g / L, and all the other are water.

[0062] This embodiment also proposes a method for processing the эи768 stainless steel stage 1 compressor blade using the solution of the эи768 stainless steel workpiece chemically processed, and its specific process is:

[0063] Step 1, prepare the solution. Prepare one liter of solution in proportion: wherein hydrochloric acid 138ml / L, nitric acid 121ml / L, ferric chloride 450g / L, and the balance is water. A prepared solution is obtained. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com