Factory formula and technology of pineapple essence

A technology for pineapple essence and raw materials, applied in the field of daily chemical industry, can solve the problems of insufficient market demand for pineapple essence development, lack of natural taste of pineapple essence, etc., and achieves the effects of convenient operation, reduction of harmful chemical components, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

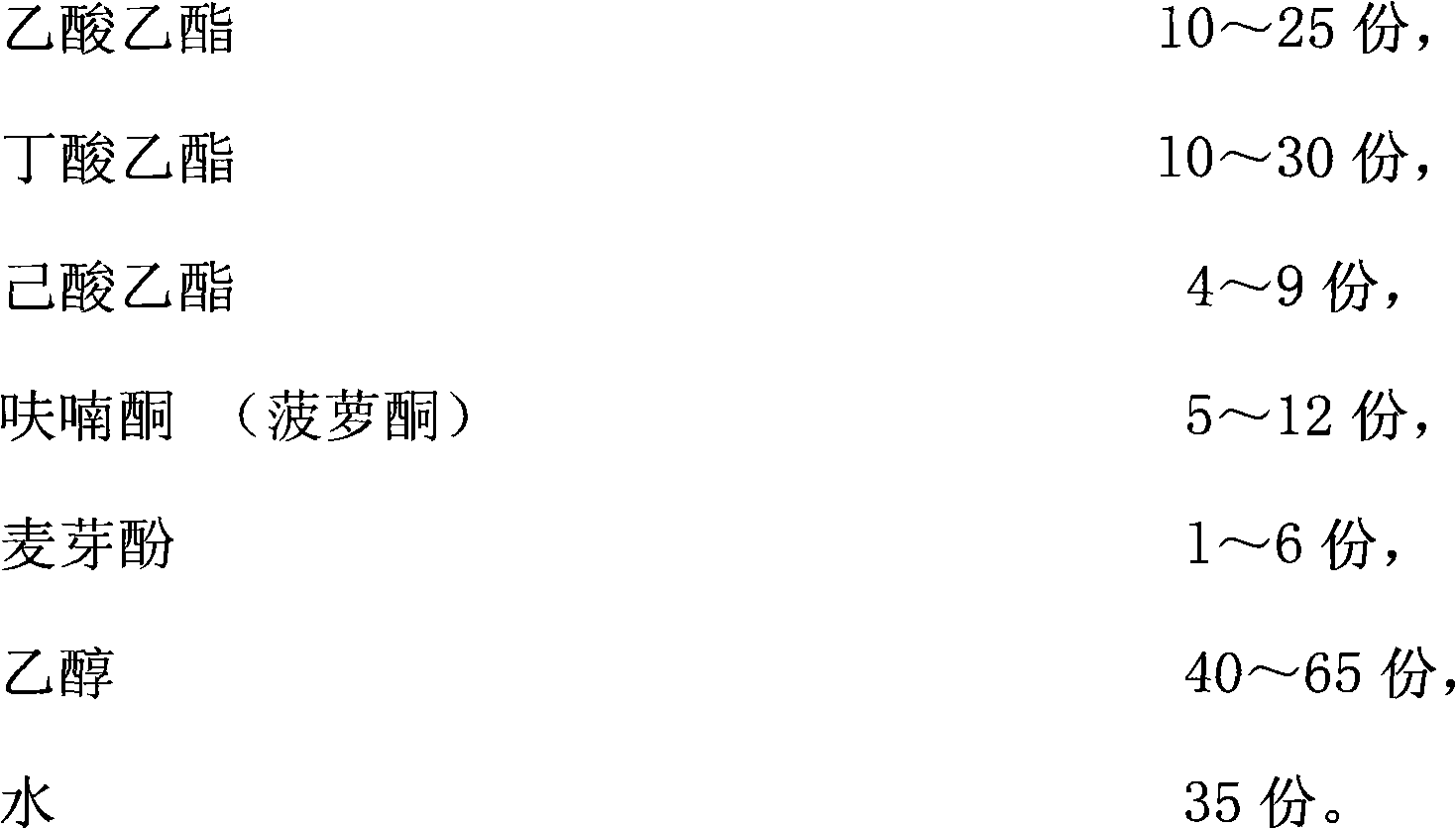

Method used

Image

Examples

Embodiment 1

[0018] Take the production of 100 grams of pineapple essence as an example: take by weighing 1.5 grams of methyl caprylate, 0.5 grams of ethylene glycol, 15 grams of ethyl acetate, 20 grams of ethyl butyrate, 5 grams of ethyl caproate, and 7 grams of furanone (pineapple ketone). grams, 3 grams of maltol, 40 milliliters of ethanol, and 35 milliliters of water.

[0019] Then proceed as follows:

[0020] (1) Furanone, maltol, and ethyl butyrate were dissolved in ethanol respectively, then methyl caprylate and ethyl acetate were added, mixed and stirred for 30 minutes, and the organic mixture was evenly mixed and transferred into the reaction kettle;

[0021] (2) After adding ethylene glycol, under the condition that the temperature of the reactor is controlled at 75-90°C, apply high pressure to carry out repeated emulsification, evaporate the alcohol and oil, stop the reaction when the particles are obtained, cancel the high pressure, and cool to 20 ℃;

[0022] (3) The granules...

Embodiment 2

[0025] Take the production of 100 grams of pineapple essence as an example: take by weighing 3 grams of methyl octanoate, 0.7 grams of ethylene glycol, 18 grams of ethyl acetate, 25 grams of ethyl butyrate, 7 grams of ethyl caproate, and 9 grams of furanone (pineapple ketone). grams, 4 grams of maltol, 70 milliliters of ethanol, and 35 milliliters of water.

[0026] Then proceed as follows:

[0027] (1) Furanone, maltol, and ethyl butyrate were dissolved in ethanol respectively, then methyl caprylate and ethyl acetate were added, mixed and stirred for 30 minutes, and the organic mixture was evenly mixed and transferred into the reaction kettle;

[0028] (2) After adding ethylene glycol, under the condition that the temperature of the reactor is controlled at 75-90°C, apply high pressure to carry out repeated emulsification, evaporate the alcohol and oil, stop the reaction when the particles are obtained, cancel the high pressure, and cool to 20 ℃;

[0029] (3) The granules o...

Embodiment 3

[0032] Take the production of 100 grams of pineapple flavor as an example: Take the production of 100 grams of pineapple flavor as an example: Weigh 3 grams of methyl octanoate, 0.7 grams of ethylene glycol, 20 grams of ethyl acetate, 30 grams of ethyl butyrate, and 9 grams of ethyl caproate gram, 9 grams of furanone (pineapple ketone), 6 grams of maltol, 60 milliliters of ethanol, and 35 milliliters of water.

[0033] Production technology is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com