Method for preparing high-quality bio-oil based on microwave activation and pyrolysis gas recycling

A technology of microwave activation and pyrolysis gas, which is applied in the petroleum industry and the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of uneven heating of raw materials, intensified coking reaction of lignin, easy deactivation of catalysts, etc., and achieves unstable bio-oil. Effects of low component content, faster molecular free movement, and increased amorphous properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

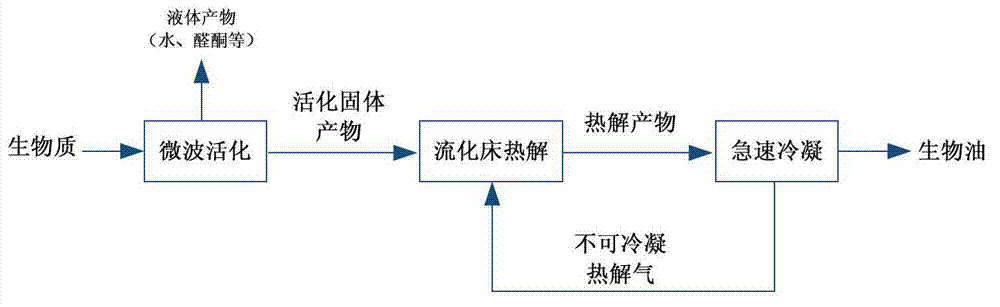

Method used

Image

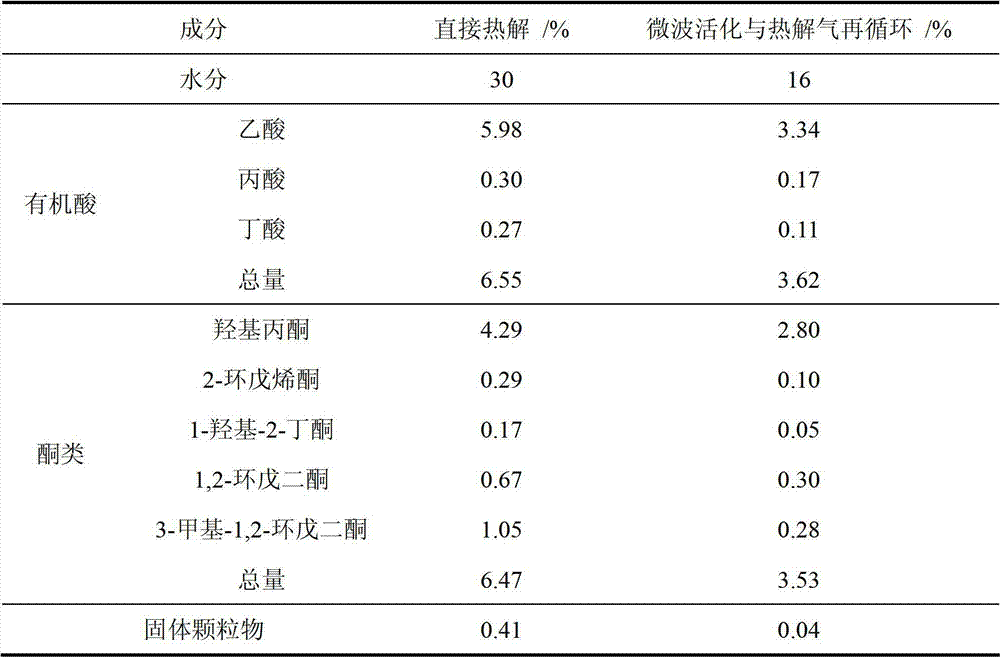

Examples

Embodiment Construction

[0018] The present invention will be further described in detail through specific embodiments below.

[0019] This embodiment takes the following steps:

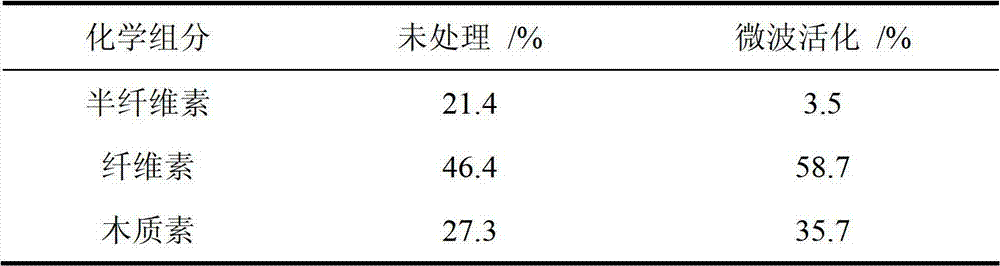

[0020] (1) Microwave activation pretreatment: Dry and crush the pine wood raw material and put it into the microwave pyrolysis reactor for microwave activation pretreatment at 180°C. The residence time of the pine wood raw material in the microwave pyrolysis reactor is 1min to maximize the decomposition Remove hemicellulose in pine wood while reducing pyrolysis reactions of other components. The chemical composition comparison of pine wood before and after microwave activation is shown in Table 1:

[0021] Table 1 Analysis of chemical components of pine raw materials before and after microwave activation

[0022]

[0023] In this embodiment, pine wood is used as raw material, but other straw and woody biomasses are used. According to the different raw materials, the microwave pyrolysis reactor is controlled at 150-200°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com