Anti-static gasket for stacking beverage and food containers and manufacturing method thereof

A food container, anti-static technology, used in coatings, conductive coatings, layered products, etc., can solve the problems of foreign matter sticking, dust pollution and surface scratching, etc., to facilitate the separation of laminated containers, reduce sliding phenomenon, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

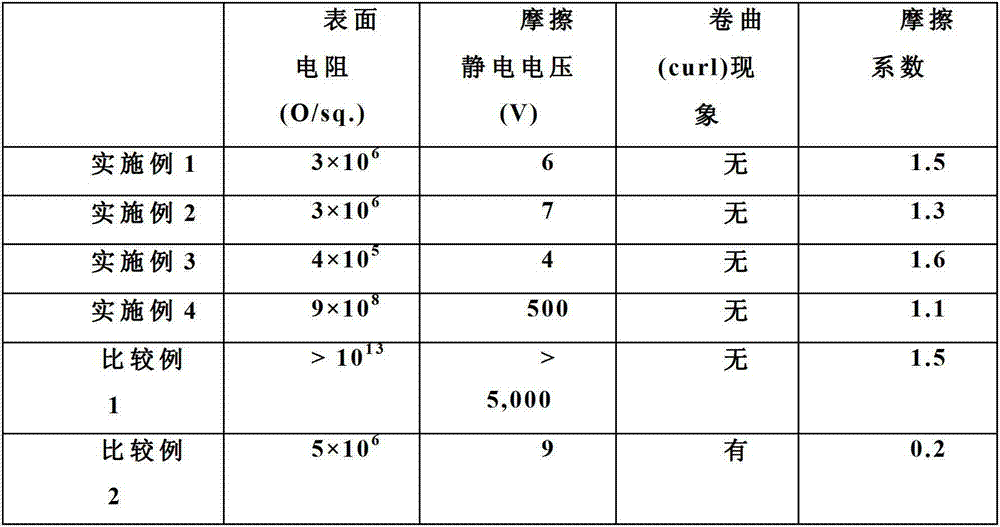

[0063] 1-1. A thermosetting antistatic material was produced by mixing: 10% by weight of polyethylene (3,4-ethylenedioxythiophene) (Baytron, PH), 5% of acrylic-amino Potassium ester polymer (Stahl Asia Pte Ltd., WF-4644), 31.5% water, 50% isopropanol, 3% 1-methyl-2-pyrrolidone and 0.5% slip agent (silicon resin series ).

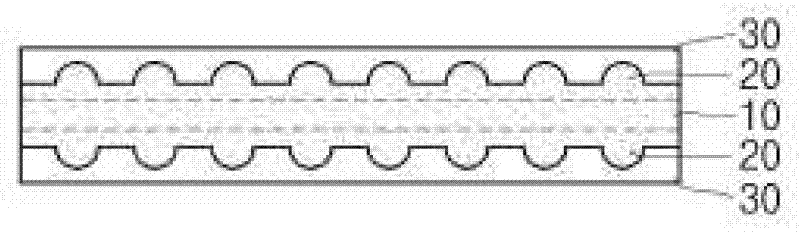

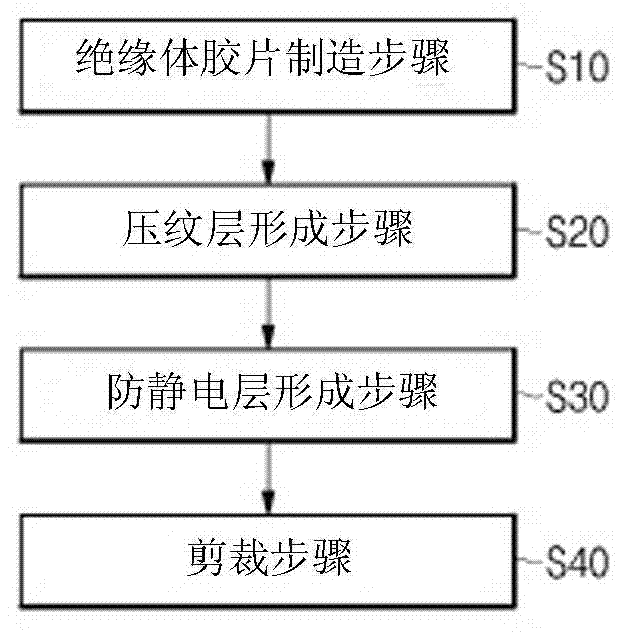

[0064] 1-2. Using an extruder at 170-190°C, and through the T-plate pressing process, the polypropylene resin is extruded, and then passed through an embossing roll, a polishing roll or a cooling roll to produce an embossed Layer 0.5mm thick polypropylene gasket, and then apply the above thermosetting antistatic material with a thickness of 0.1μm (coating film after drying) on one side surface of the above polypropylene gasket by gravure printing coating method, And carry out thermosetting treatment at a temperature of 60-80°C, and apply thermosetting antistatic material and thermosetting treatment on the reverse side in the same way to manufacture antist...

Embodiment 2

[0067] 2-1. A light-hardening nano hardening substance is produced by mixing the following substances: by weight percentage, 50% acrylic unit (20% polydipentaerythritol hexaacrylate, 30% pentaerythritol triacrylate, Korea Miwon business), 10% of the alkyl-alkoxy acrylic unit [poly-dipentaerythritol hexaepoxyacrylate (Dipentaerythritol hexaetoxyacrylate: DPHEA), SATOMER Co.)], 25% of the inorganic oxide---water-dispersed silicon Stone sol (Nalco 2327, NALCO Co.), 5% silane compound [3-methacryloxypropyltrimethoxysilane, (3-methacrylocxa propyl trimethoxy silane), Shin-etsu chemical Co.], 10% A mixture of gum stabilizers (acryloyl morpholine, SATOMERCo.).

[0068]2-2. Add the following substances to produce a light-hardening antistatic material: by weight percentage, 15% of the light-hardening nano-hardening substance produced in the above-mentioned 2-1 step, 10% polyethylene (3,4-B Dioxythiophene) (Baytron PH, Bayer Co.), 1% photoinitiator (Igacure 184, Ciba Geigy Co.), 0.2% s...

Embodiment 3

[0071] 3-1. A thermosetting antistatic material is produced by mixing the following components, 2% of carbon nanotubes (MWCNT, Nanocyl), 5% of acrylic acid-potassium urethane polymer (Stahl Asia Pte Ltd., WF- 4644), 42.5% water, 50% isopropyl alcohol, 0.5% slip agent (silicon resin series).

[0072] 3-2. Except for the method of producing thermosetting antistatic material in the above step 3-1, adopt the same method as the above Example 1 to produce an antistatic gasket for lamination of beverage and food containers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com