Catalyst for producing propane and high octane number gasoline by using butane, and preparation method thereof

A high-octane gasoline and catalyst technology, which is applied in the non-hydrogenation conversion of alkanes into small molecular alkanes and gasoline components, can solve the problems of low propane content, not very good ethylene cracking raw materials, and high butane content, and achieve dry Low gas yield, reduced olefin content, good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

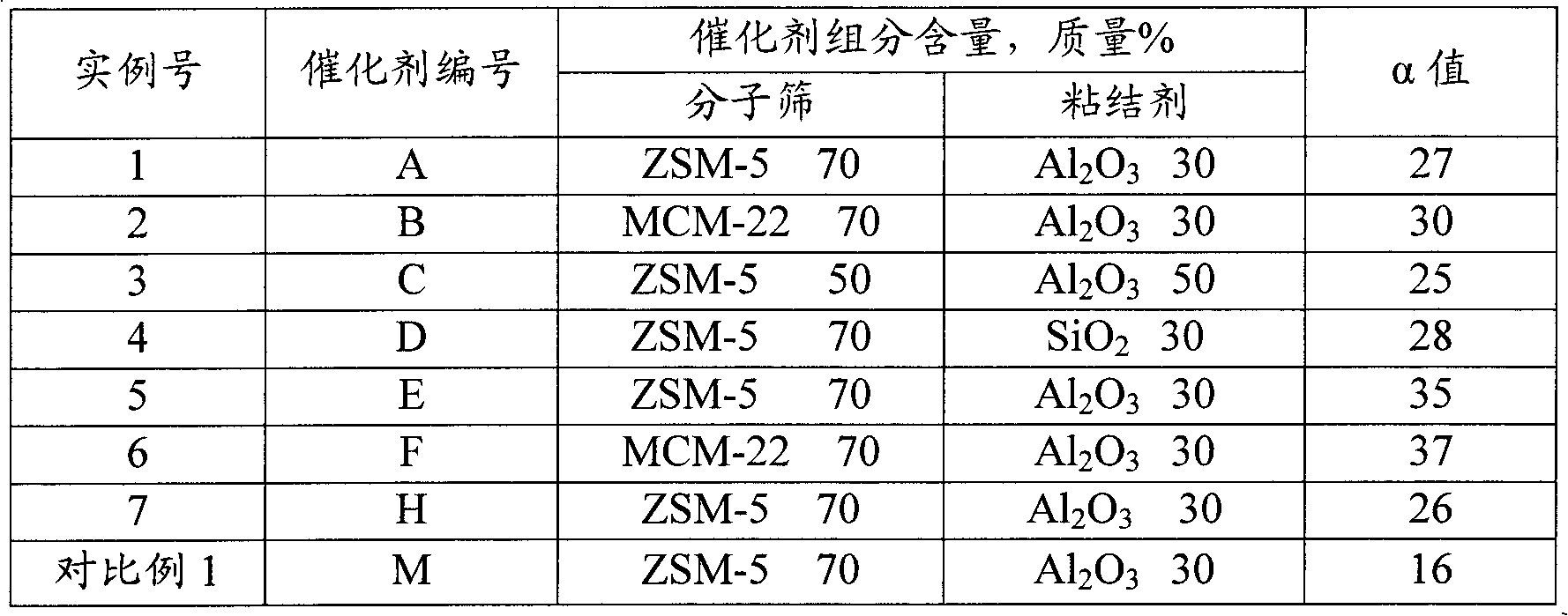

[0018] The preparation method of the catalyst provided by the present invention comprises mixing the mesoporous silica-alumina zeolite and the precursor of the binder, extruding into rods, drying, roasting, and treating with steam at 430-570°C. The mass ratio of the catalyst is 0.5-5.0, so that the α value of the catalyst after steam treatment is 25-50, preferably 25-40.

[0019] In the above method, the mesoporous silica-alumina zeolite is selected from one of ZSM-5, ZSM-11, ZSM-12, ZSM-35, MCM-22 and MCM-41 zeolites or any two or more of them The form in which the zeolite exists is preferably the hydrogen form. The binder precursor is preferably pseudo-boehmite, boehmite or silica sol.

[0020] The molding method of the catalyst of the present invention is: mixing the mesoporous silica-alumina zeolite and the precursor of the binder, adding an appropriate amount of water and a peptizer to knead and extrude into a strip. The peptizer is selected from nitric acid, hydrochlori...

example 1

[0029] The following examples prepare catalysts of the invention.

[0030] Get 130 gram of silicon oxide / alumina mol ratios and be 56 HZSM-5 zeolite powder (build factory molecular sieve factory production), 70 gram aluminum hydroxide powders (Qilu Catalyst Factory production, dry basis alumina content 75 mass %), add 90 Milliliters of water and 4 milliliters of nitric acid solution with a concentration of 1% by mass were kneaded, extruded, dried at 110° C. for 4 hours, and calcined at 550° C. for 4 hours. Then put it into a tubular reactor, raise the temperature to 550° C. in an air stream under normal pressure, and pass in steam for 4 hours, with a total water intake of 300 grams. The composition and α value of the prepared catalyst A are shown in Table 1.

example 2

[0032] Getting 130 grams of silicon oxide / alumina mol ratio is the hydrogen type MCM-22 zeolite powder (production of molecular sieve factory) of 30, 70 grams of aluminum hydroxide powder (production of Qilu Catalyst Factory, dry base alumina content 75 mass %), Add 90 milliliters of water and 4 milliliters of nitric acid solution with a concentration of 1% by mass, knead, extrude, dry at 110° C. for 4 hours, and roast at 550° C. for 4 hours. Then put it into a tubular reactor, raise the temperature to 550° C. in an air stream under normal pressure, and pass in steam for 4 hours, with a total water intake of 300 grams. The composition and α value of the prepared catalyst B are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com