Deep evaporating method for phenol hydroxylated liquid detarring tower

A technology of phenol hydroxylation solution and detar tower is applied in steam generation method using heat carrier, chemical instrument and method, tar processing by distillation method, etc., to improve product quality stability, improve working environment, and easy to handle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

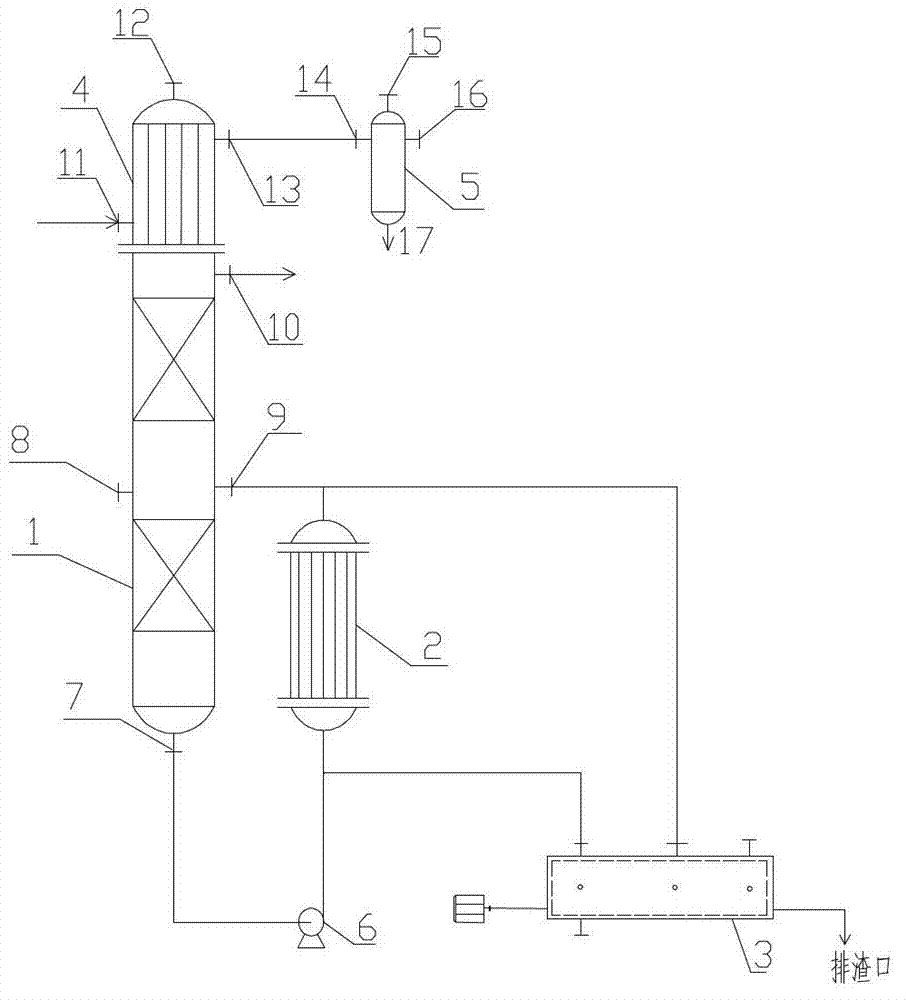

[0017] The distillation condensation process of embodiment 1 feed intake 1.0 kilograms / hour hydroquinone tar

[0018] In the rectification tower 1, the side line liquid phase material inlet 8 is fed with a feed rate of 1.0 kg / h, and the rectification tower tower liquid is injected into the bottom reboiler 2 and the biaxial stirring through the tower bottom material outlet 7 through the circulation pump 6 Reboiler 3, control the flow of heat transfer oil, control the temperature in the bottom reboiler and the twin-shaft stirring reboiler at 210°C, control the internal pressure of the rectification tower and the twin-shaft stirring reboiler to 5KPa, and control the internal pressure of the tower bottom reboiler And after the material in the twin-shaft stirring reboiler is heated, the volatile components become steam and enter the rectification tower through the pipeline through the side line gas phase material inlet, and the evaporation rate is 0.9 kg / hour, and the gas phase at t...

Embodiment 2

[0020] The distillation condensation process of embodiment 2 feeding intake 1.5 kilograms / hour hydroquinone tar

[0021] In the rectifying tower 1, the side line liquid phase material inlet 8 is fed with a feed rate of 1.5 kg / h, and the rectifying tower tower liquid is injected into the bottom reboiler 2 and the twin-shaft stirring through the tower bottom material outlet 7 through the circulation pump 6 Reboiler 3, control the flow of heat transfer oil, control the temperature in the bottom reboiler and the twin-shaft stirring reboiler at 215°C, control the internal pressure of the rectification tower and the twin-shaft stirring reboiler to 7KPa, and control the internal pressure of the bottom reboiler And after the material in the biaxial stirring reboiler is heated, the volatile components become steam and enter the rectification tower through the side line gas phase material inlet through the pipeline, and the evaporation rate is 1.2 kg / hour, and the gas phase at the top of...

Embodiment 3

[0023] The distillation condensation process of embodiment 3 feeding intake 2.0 kilograms / hour hydroquinone tar

[0024] In the rectification tower 1, the side line liquid phase material inlet 8 is fed with a feed rate of 2.0 kg / h, and the rectification tower tower bottom liquid passes through the tower bottom material outlet 7 and enters the tower bottom reboiler 2 and twin-shaft stirring through the circulation pump 6 Reboiler 3, control the flow rate of the heat transfer oil, control the temperature in the bottom reboiler and the twin-shaft stirring reboiler at 220°C, control the pressure in the rectification tower and the twin-shaft stirring reboiler to 10KPa, and the bottom reboiler And after the material in the biaxial stirring reboiler is heated, the volatile components become steam and enter the rectification tower through the side line gas phase material inlet through the pipeline, and the evaporation rate is 1.5 kg / hour, and the gas phase at the top of the rectificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com