Recycled magnesium alloy, process for producing the same, and magnesium alloy

一种再生镁合金、制造方法的技术,应用在工艺效率的提高、回收利用技术等方向,能够解决制造成本增加、降低环境负担、抑制镁基构件再生性等问题,达到提高再生性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

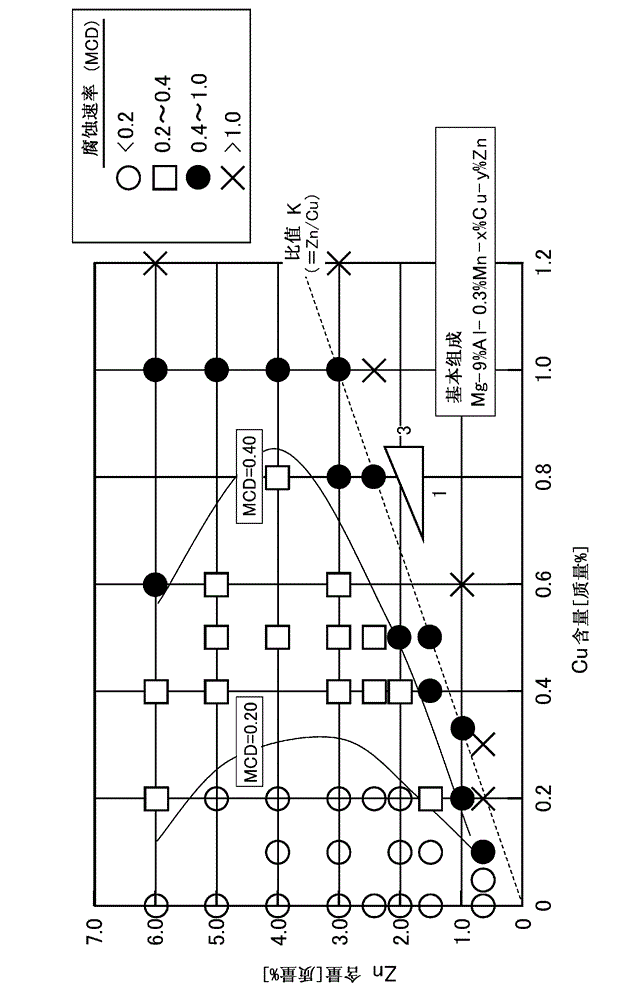

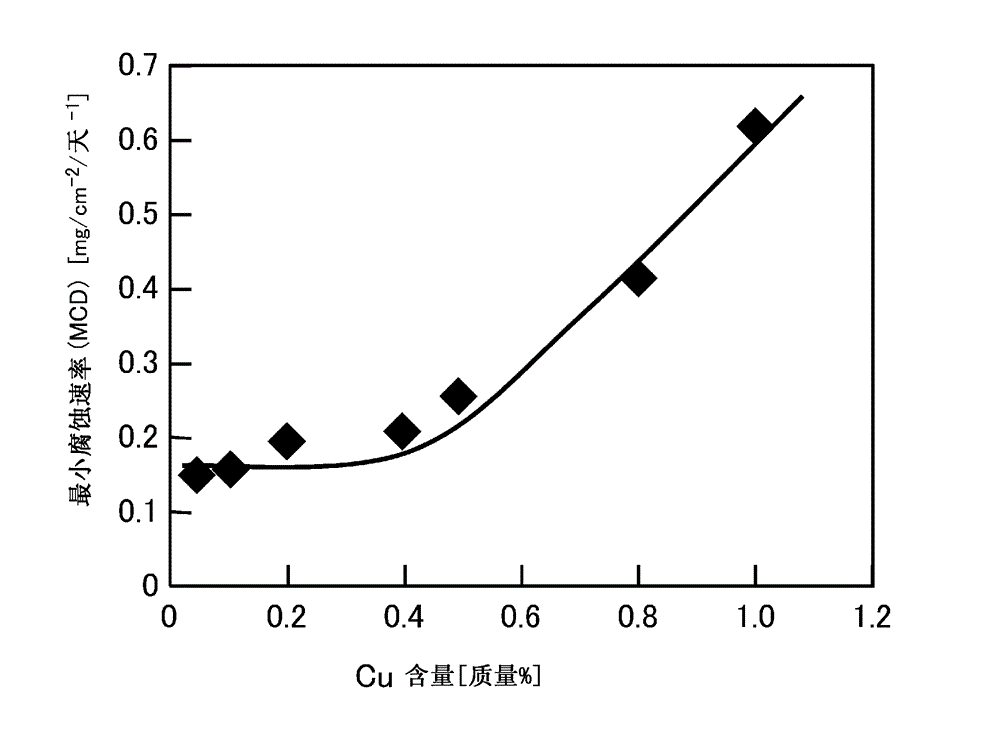

[0115] The present invention will be described more specifically by way of examples.

[0116]

[0117] Samples having the chemical compositions shown in Tables 1 to 7 were prepared by using various commercially available raw materials. The R.E. used was commercially available Mm (Ce: 52%; La: 25%; Nd: 16%; and Pr: 5%).

[0118] Specifically, first, a commercially available raw material containing pure metal was introduced into a crucible formed of high Cr alloy steel (JIS SUS430) and having an inner diameter of 80 mm and a height of 230 mm, and was melted by an electric furnace, thereby obtaining a molten metal (Raw material molten metal) (melting step). The chemical composition of the molten metal was adjusted to various compositions shown in Tables 1 to 7 and kept at 750° C. (adjustment step). The thus-obtained molten metal (adjusted molten metal) was filled in a cavity of a metal mold and rapidly cooled and solidified, whereby samples comprising die-castings having vari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com