Photovoltaic grid-connected micro-inverter system

A micro-inverter, photovoltaic technology, applied in photovoltaic power generation, climate change adaptation, single-grid parallel feeding arrangement, etc., can solve problems such as energy waste of solar panel arrays, dangerous high-voltage DC circuits, system failures, etc., to achieve convenient The effect of capacity expansion and maintenance, overcoming weak links, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

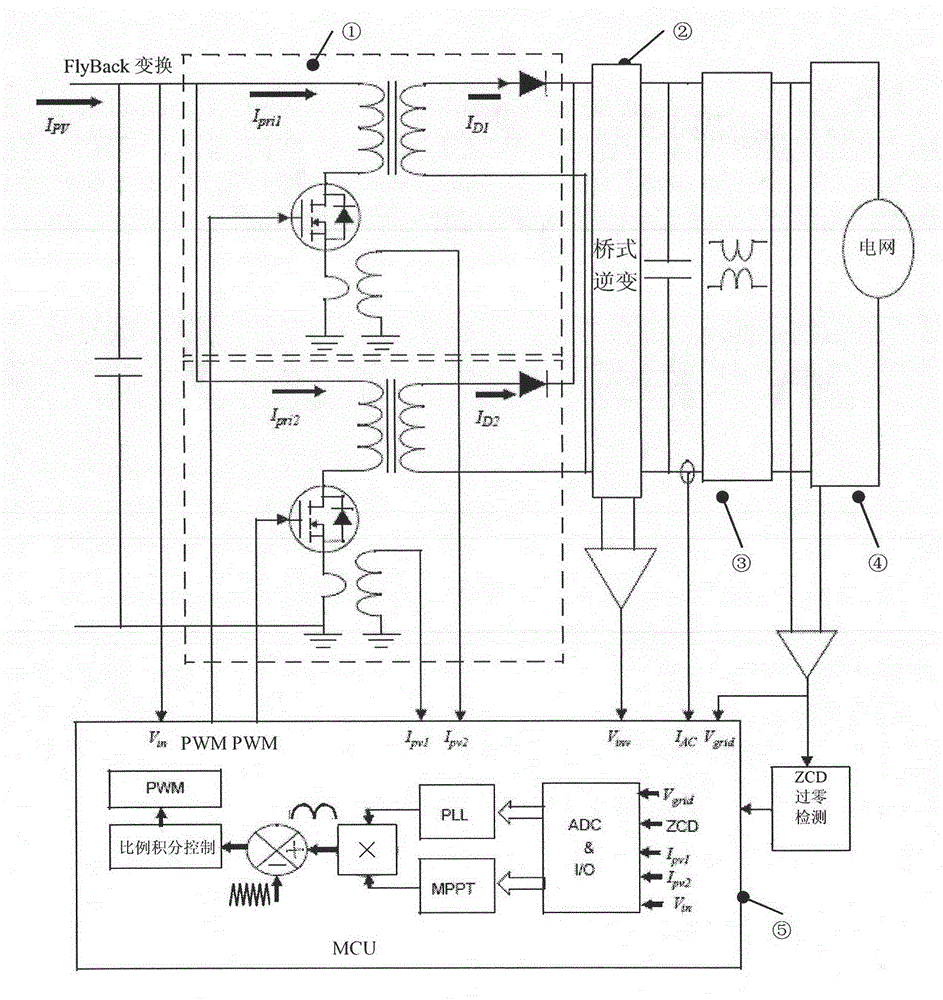

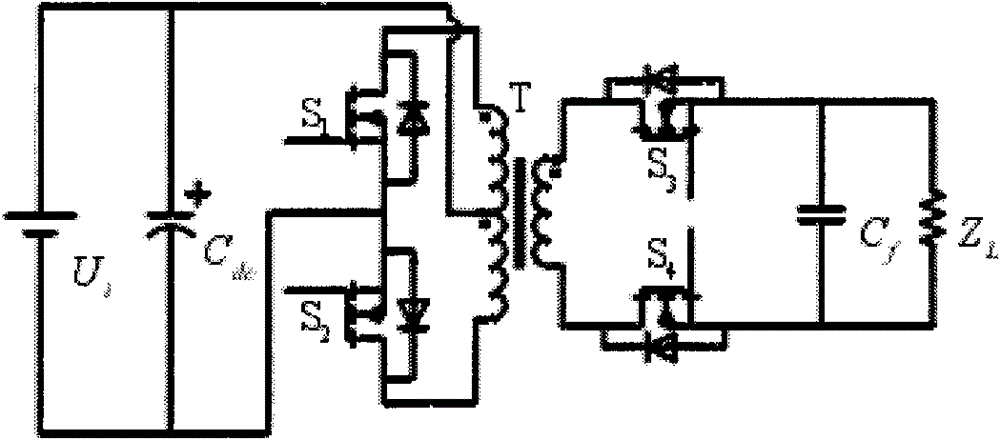

[0022] Such as Figure 1 to Figure 11 As shown, the specific implementation method is: the FlyBack conversion circuit ① uses the structure of the push-pull circuit topology to perform high-frequency conversion of the current source, and the bridge inverter circuit ② performs power frequency inversion. It can be seen that the circuit structure is simple: the primary side of the transformer is two push-pull high-frequency SPWM switching tubes, which perform sinusoidal modulation of the incoming current and MPPT control; the transformer is used for isolation in the middle; the two branches of the secondary side each work half frequency cycle. Among them, each branch has a switch tube controlled by power frequency, and the two switch tubes on the secondary side are complementary to conduct and synchronized with the power grid.

[0023] According to the polarity of the output voltage and the secondary inductor current, the circuit has four operating modes. Each working mode is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com