Concrete restrained contraction ring crack resistance test device and test method

A technology for crack resistance test and concrete specimen, applied in the direction of material inspection products, etc., can solve the problem of non-cracking, achieve good restraint, reduce the influence of human factors, and achieve accurate and objective effects of concrete crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

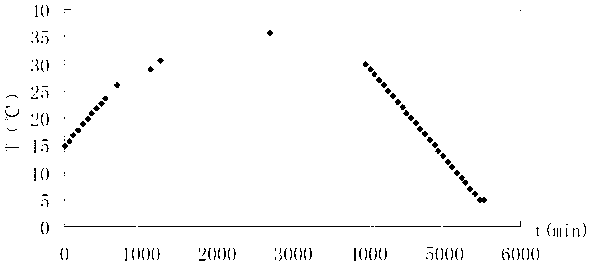

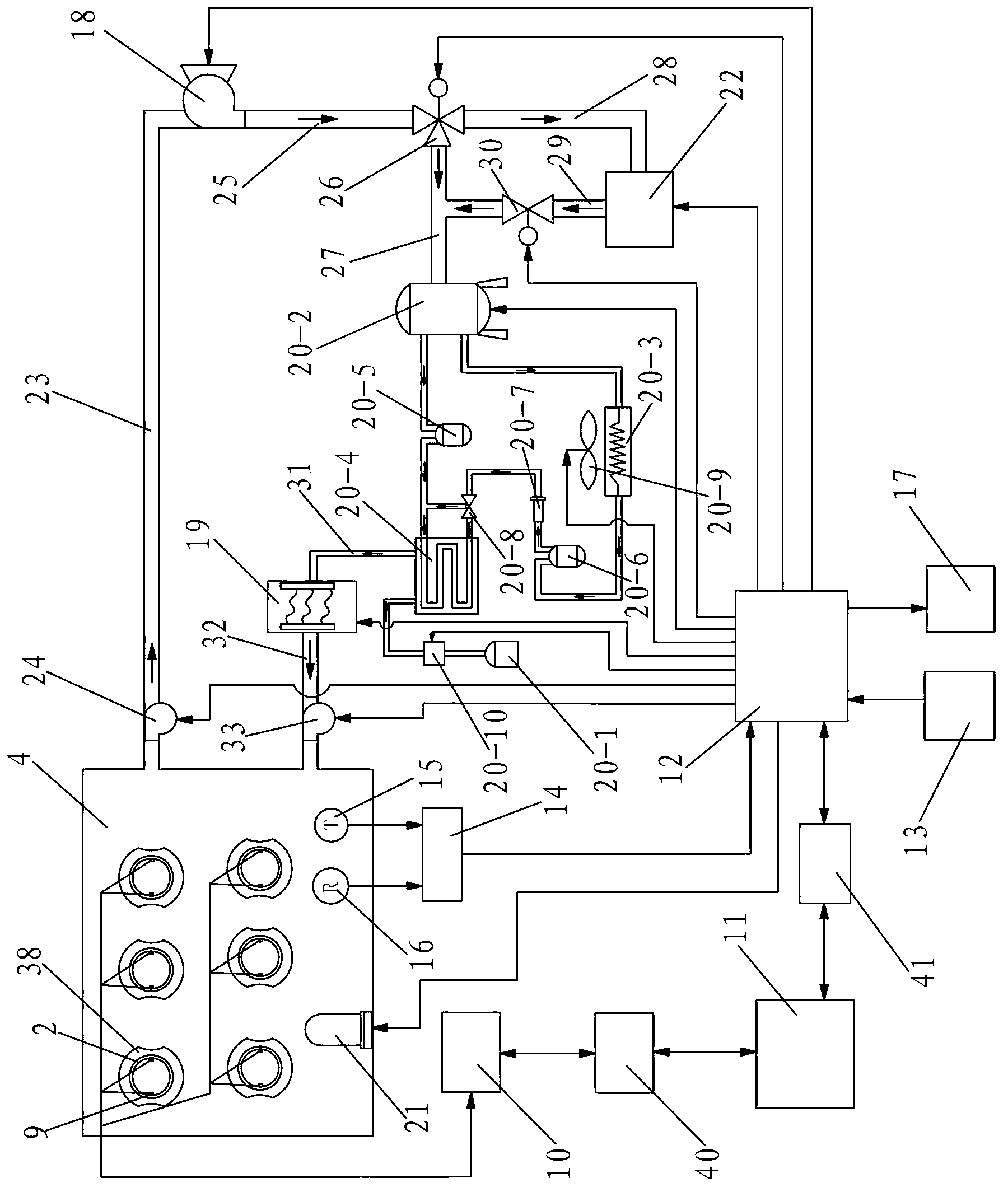

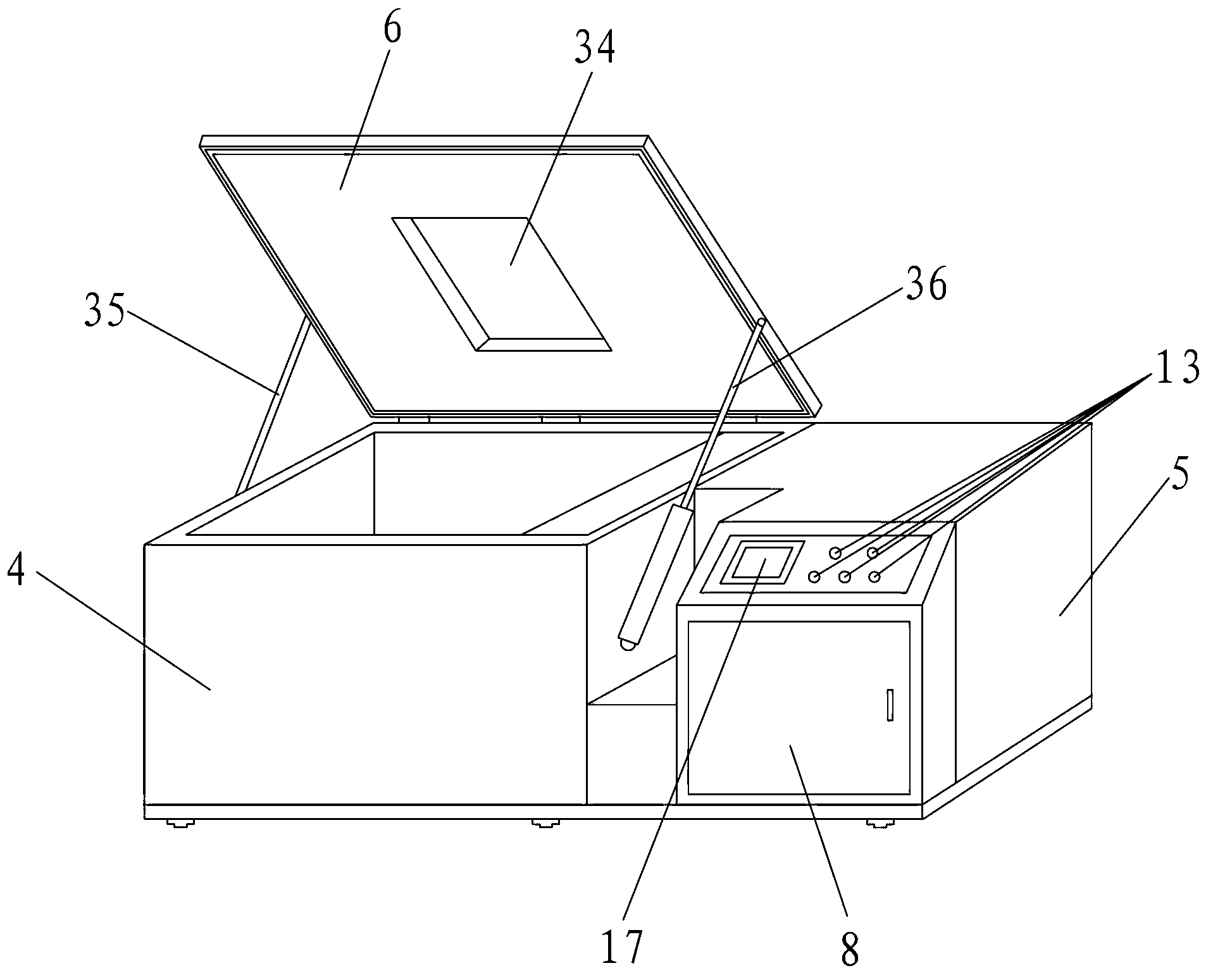

[0071] Such as Figure 1 to Figure 7 As shown, the concrete constrained shrinkage ring crack resistance test device of the present invention includes a constrained shrinkage ring assembly for forming the concrete specimen 38 and an automatic maintenance device for automatically maintaining the concrete specimen 38, and using It is an intelligent measurement and control system for detecting the crack resistance of the concrete specimen 38 and monitoring the automatic maintenance equipment. The ring-shaped outer mold 3 on the periphery of the constraining shrinkage ring 2, the inner side of the outer mold 3 is symmetrically provided with two sections of anti-arc molds 39, and the two ends of each section of the anti-arc mold 39 are connected to the The inner wall of the outer mold 3 is fixedly connected; the automatic maintenance equipment includes a curing box and an automatic temperature and humidity adjustment system for automatically adjusting the temperature and humidity in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com