Method for measuring content of trace chlorine in high pure, ultra pure ammonia

A technology of ultra-pure ammonia and chlorine content, which is applied in the direction of chemical analysis by titration, which can solve the problems of cumbersome operation and poor repeatability, and achieve the effects of high measurement accuracy, fast analysis speed and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] 1. Reagents

[0015] (1) Primary distilled water or high-purity water;

[0016] (2) Glacial acetic acid;

[0019] (5) Iodine: Use 20-40 mesh particles to prepare reference electrodes;

[0020] (6) Isooctane (chlorine-free);

[0021] (7) Dimethyl dichloroether (for preparing standard samples);

[0022] (8) Electrolyte: Dissolve 0.5g of potassium iodide and 0.6g of sodium azide in 1000ml of 0.5% acetic acid aqueous solution, put it in a brown bottle, and put it in a dark and ventilated place for later use; the validity period is two weeks.

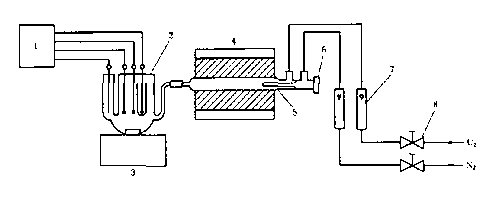

[0023] 2. Instruments and equipment

[0024] RPA-200A Micro Coulomb Analyzer Jiangsu Jianghuan Analytical Instrument Co., Ltd.

[0025] 3. Fundamentals

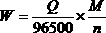

[0026] The sample is injected into the cracking tube, mixed with oxygen and burned, and the organic chlorine in the sample is converted into chloride ion, which is carried into the titration cell by the carrier gas and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com