Low-grade-energy drive CO2 absorption refrigeration system

An absorption refrigeration, low-grade technology, applied in refrigerators, adsorption machines, refrigeration and liquefaction, etc., can solve the problems of high heat source temperature requirements, difficulty in continuous and stable operation, and low efficiency, so as to simplify peripheral equipment and improve reliability Sexuality and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

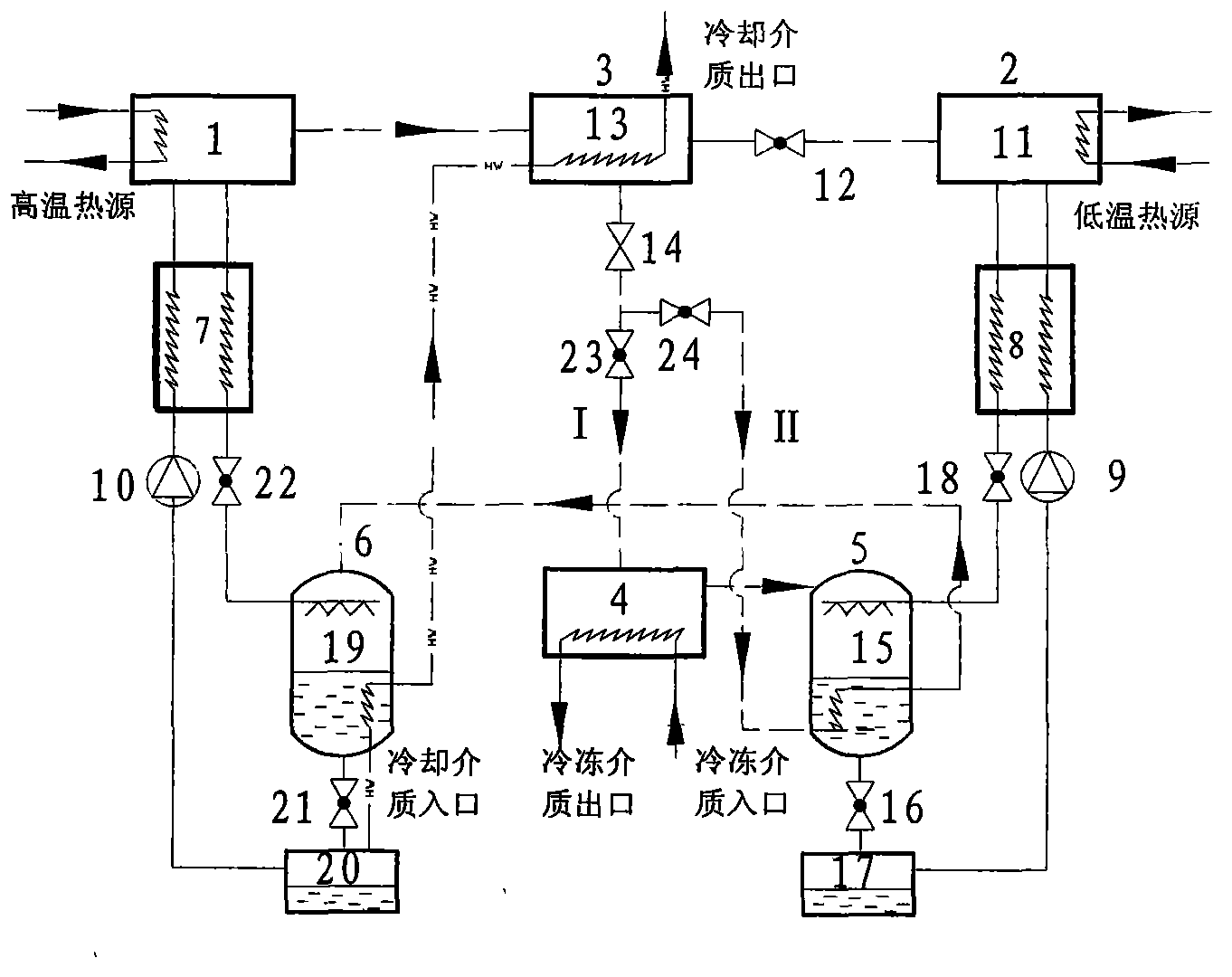

[0027] figure 1 It is embodiment 1 of the present invention, that is, CO driven by low-grade dual heat sources 2 Schematic diagram of the basic structure of an absorption refrigeration system. Such as figure 1 As shown, it includes a high-temperature generator 1, a low-temperature generating module 2, a condensation module 3, an evaporator 4, an absorption evaporation module 5, an absorption module 6, a first regenerator 7, a second regenerator 8, and a second solution pump 9 , the first solution pump 10, the decompression device 14, the refrigerant outlet of the high-temperature generator 1, the outlet of the refrigerant of the low-temperature generation module 2 are respectively connected with the inlet of the condensation module 3, and the first outlet 1 of the refrigerant of the condensation module 3 is refrigerated with the evaporator 4 The refrigerant inlet is connected, the refrigerant outlet of the evaporator 4 is connected to the refrigerant inlet of the absorption ...

Embodiment 2

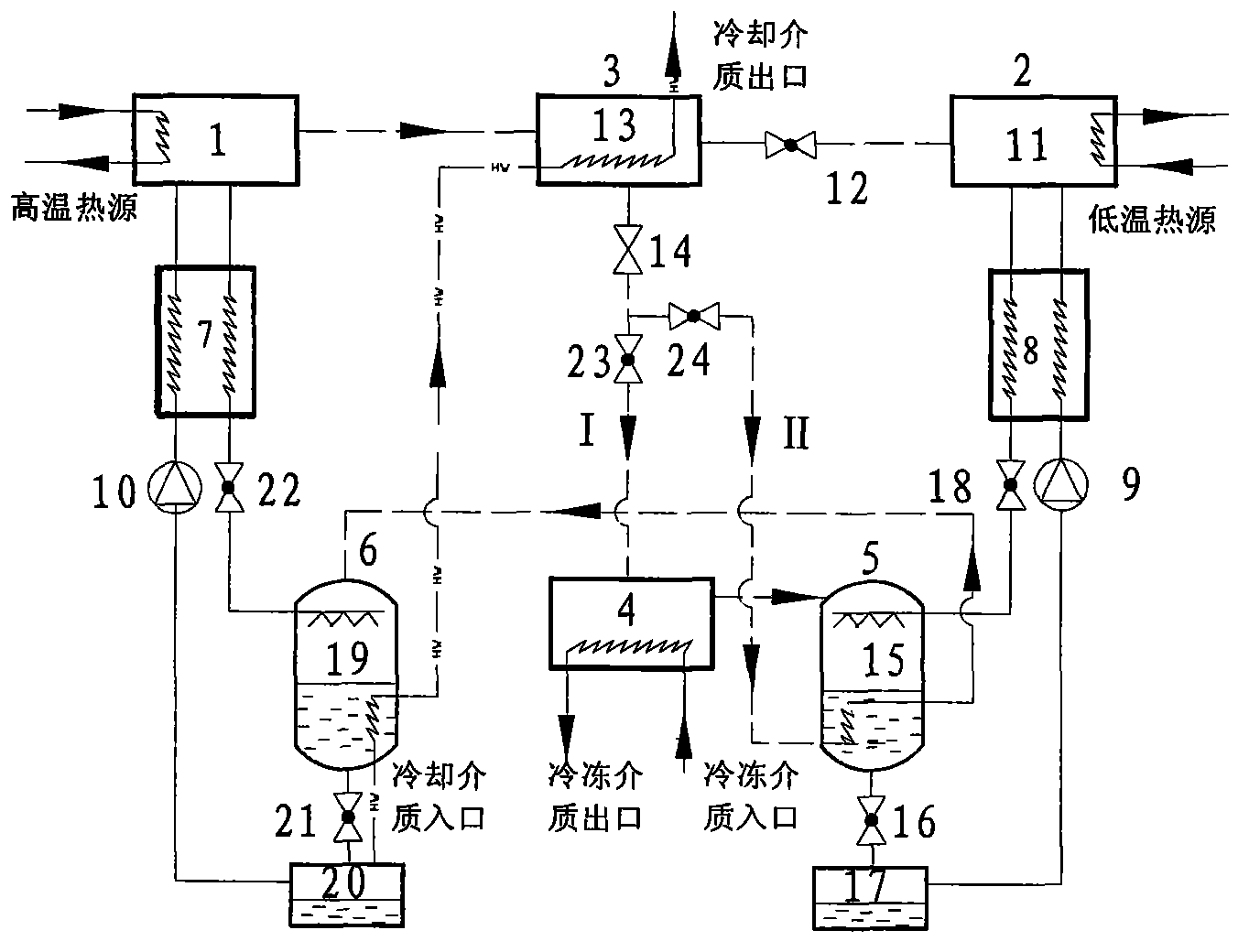

[0042] figure 2 It is Example 2 of the present invention. In order to solve the shortage of high-temperature heat source supply, CO 2 The problem of insufficient gas generation, this embodiment will come from the CO with higher outlet temperature of the low-temperature generation module 2 2 One of the refrigerant gas is used as a supplementary steam source for the cycle, and the other one enters the absorption module 6 together with the higher temperature refrigerant gas from the absorption evaporation module 5 to be absorbed, so as to ensure the stable operation of the system, reduce the cycle rate, and improve the system efficiency. COP.

[0043] Such as figure 2 As shown, it includes a high-temperature generator 1, a low-temperature generating module 2, a condensation module 3, an evaporator 4, an absorption evaporation module 5, an absorption module 6, a first regenerator 7, a second regenerator 8, and a second solution pump 9 , the first solution pump 10, the refrig...

Embodiment 3

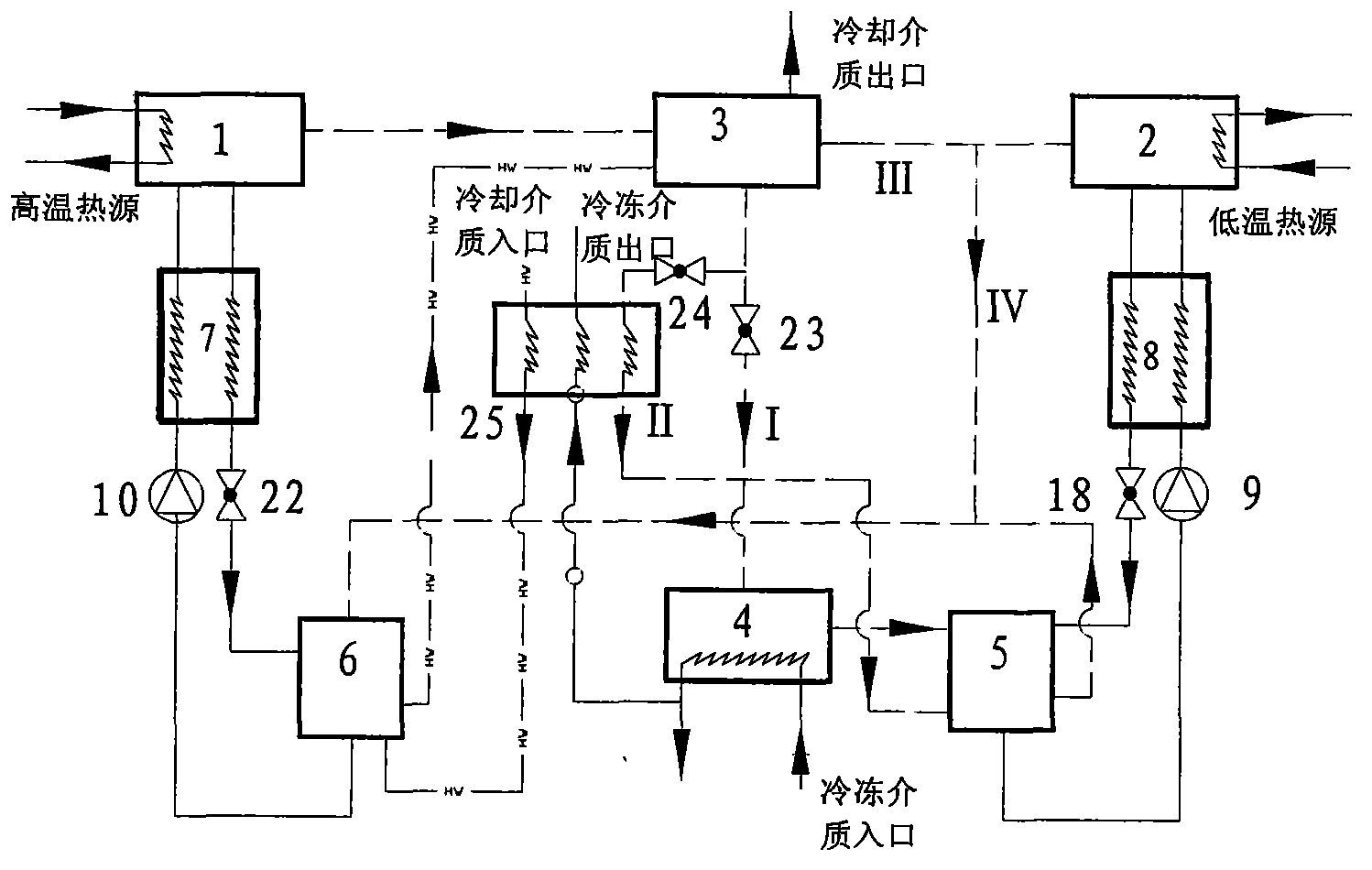

[0050] image 3 It is Example 3 of the present invention. In order to effectively reduce the refrigerant CO leaving the condensing module 3 2 Therefore, the energy recovery heat exchanger 25 is added at the second outlet II of the refrigerant of the condensing module 3, the outlet of the brine, and the inlet of the cooling medium to recover the cooling capacity of the brine and the cooling medium, so as to more effectively reduce the cycle rate and The temperature of the solution at the outlet of the absorber further increases the COP of the system.

[0051] Such as image 3 As shown, it includes a high-temperature generator 1, a low-temperature generating module 2, a condensation module 3, an evaporator 4, an absorption evaporation module 5, an absorption module 6, a first regenerator 7, a second regenerator 8, and a second solution pump 9 , the first solution pump 10, the energy recovery heat exchanger 25, the refrigerant outlet of the high-temperature generator 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com