Demulsification method by soybean grease microbe extraction through aqueous enzymatic method

A technology of soybean oil and water enzymatic method, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., and can solve the problems of low demulsification rate and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Screening test for optimal compound ratio of mixed demulsifiers

[0028] 1 Materials and methods

[0029] 1.1 Test raw materials

[0030] Dehulled Soybean Flakes Harbin Jiusan Oil Group protex-6L alkaline endoprotease Danish novo company Bacillus mohewei Key Laboratory of Northeast Agricultural University Bacillus subtilis Key Laboratory of Northeast Agricultural University Nocardia sludge Key Laboratory of Northeast Agricultural University MMSM inorganic salt liquid medium NH 4 NO 3 4.0g, K 2 HPO 4 4.0g, KH 2 PO 4 6.0g, MgSO 4 ·H 2 O 0.2g, trace element solution 1mL, liquid paraffin 4% (v / v), yeast extract 1.0g, glucose 10.0g, deionized water 1000mL. Sterilize at 121°C for 15 minutes.

[0031] 1.2 Test instruments and equipment

[0032] instrument Manufacturer CX-500 Ultrasonic Cleaning Machine Beijing Second Medical Equipment Factory Autoclave Tianjin Test Instr...

Embodiment 2

[0062] Embodiment 2: the screening experiment of the optimal parameter of the fermentation of mixed demulsifier demulsification

[0063] Based on the optimal compound ratio of the compound biological demulsifier determined in Example 1, the fermentation test of the single-factor compound biological demulsifier was carried out to determine the fermentation process parameters (shaking table speed, inoculum size, culture temperature, culture time) range. Taking the demulsification rate as an investigation index, a response surface design experiment with 4 factors and 5 levels was carried out.

[0064] 1 Materials and methods

[0065] 1.1 Materials and reagents

[0066] Dehulled Soybean Flakes Harbin Jiusan Oil Group protex-6L alkaline endoprotease Danish novo company Bacillus mohewei Key Laboratory of Northeast Agricultural University Bacillus subtilis Key Laboratory of Northeast Agricultural University Nocardia sludge Key Laboratory of N...

Embodiment 3

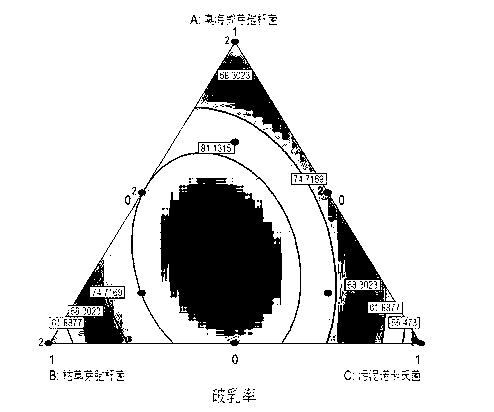

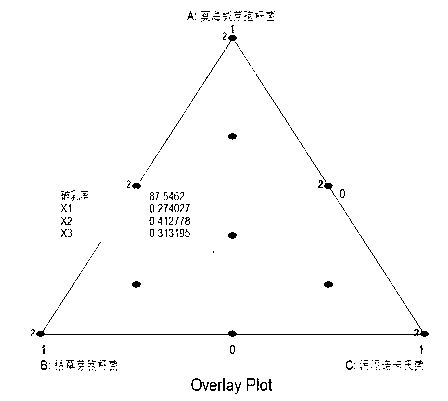

[0097] Example 3 The screening experiment of the optimal parameters of mixed demulsifier demulsification

[0098] 1.1 Materials and reagents

[0099] Dehulled Soybean Flakes Harbin Jiusan Oil Group protex-6L alkaline endoprotease Danish novo company Bacillus mohewei Key Laboratory of Northeast Agricultural University Bacillus subtilis Key Laboratory of Northeast Agricultural University Nocardia sludge Key Laboratory of Northeast Agricultural University MMSM inorganic salt liquid medium NH 4 NO 3 4.0g, K 2 HPO 4 4.0g, KH 2 PO 4 6.0g, MgSO 4 ·H 2 O 0.2g, trace element solution 1mL, liquid paraffin 4% (v / v), yeast extract 1.0g, glucose 10.0g, deionized water 1000mL. Sterilize at 121°C for 15 minutes.

[0100] 1.2 Main instruments and equipment

[0101] pHS-25 acidity meter Shanghai Weiye Instrument Factory electronic analytical balance Merlot-Toledo Instruments (Shanghai) Co., Ltd. centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com