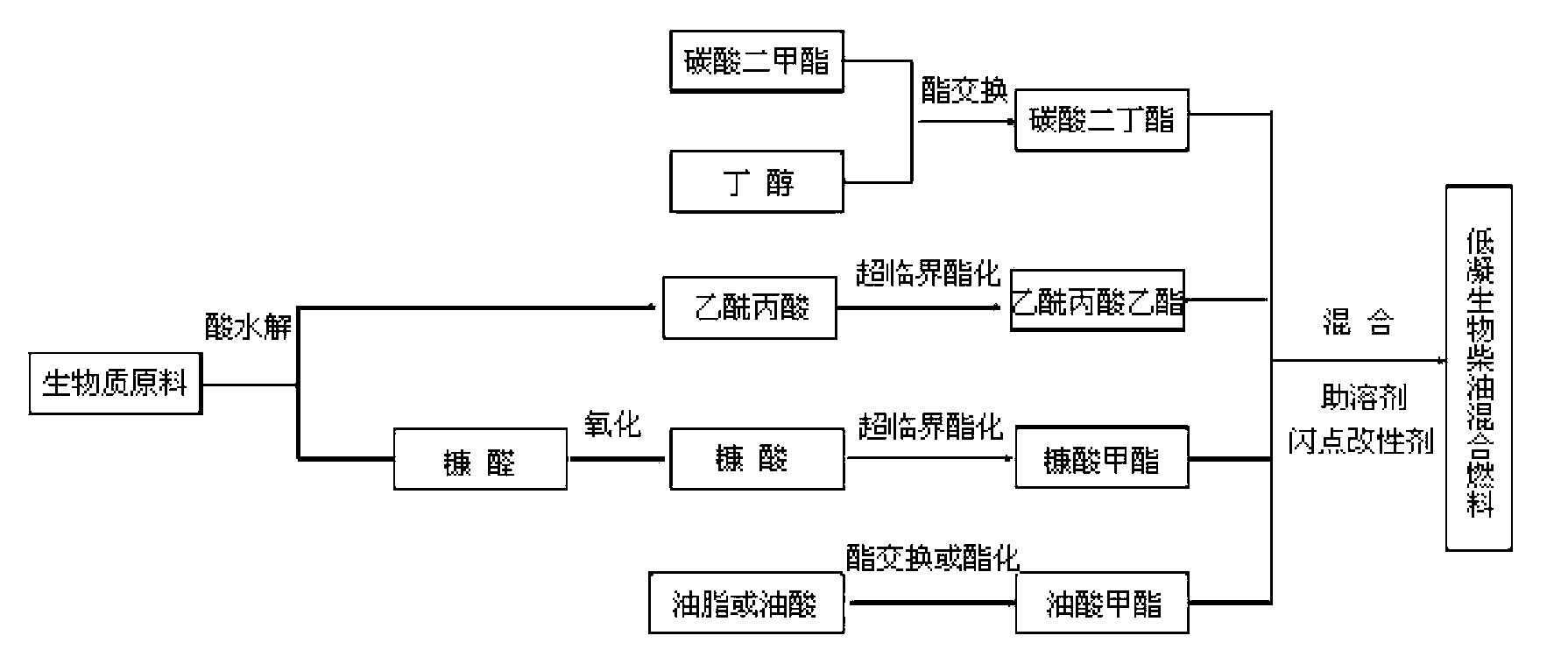

Low-freezing biodiesel combined fuel and preparation method thereof

A biodiesel and mixed fuel technology, applied in the fields of biofuels, fuels, fuel additives, etc., can solve the problems of unfavorable resource saving, renewable production of biodiesel, high cost, etc., to save crops and other mineral resources, short reaction time, The effect of stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Preparation of furfural and levulinic acid

[0044] 1. Raw material pretreatment:

[0045] After pulverizing Salix salix stubble with a moisture content of 15-20% into small particles of 0.5-1 cm, adding tap water and stirring to obtain a biomass slurry with a moisture content of 65%;

[0046] 2. The first step acid hydrolysis reaction:

[0047] Put the above-mentioned biomass slurry into the premixing tank, add formic acid solution with a mass percentage concentration of 8% into the tank, mix evenly, and send the slurry formic acid mixture into the first reactor with a plunger type high-pressure pump. The bottom of the reactor is fed with high-temperature and high-pressure steam to increase the temperature and pressure in the first reactor, and carry out the first step of acid hydrolysis reaction to obtain the first step to acid hydrolysis mixture, wherein the weight ratio of biomass slurry to formic acid solution 100:5, the temperature of the first step acid hydr...

Embodiment 2

[0082] 1. Preparation of furfural and levulinic acid

[0083] 1. Raw material pretreatment:

[0084] After pulverizing the caragana stubble with a moisture content of 15-20% into small particles of 0.5-1 cm, adding tap water and stirring to mix evenly to obtain a biomass slurry with a moisture content of 60%;

[0085] 2. The first step acid hydrolysis reaction:

[0086] Put the above-mentioned biomass slurry into the premixing tank, add formic acid solution with a mass percentage concentration of 4% into the tank, mix well, and send the slurry formic acid mixture into the first reactor with a plunger type high-pressure pump. The bottom of the reactor is fed with high-temperature and high-pressure steam to increase the temperature and pressure in the first reactor, and carry out the first step of acid hydrolysis reaction to obtain the first step to acid hydrolysis mixture, wherein the weight ratio of biomass slurry to formic acid solution 100:2, the temperature of the first s...

Embodiment 3

[0121] 1. Preparation of furfural and levulinic acid

[0122] 1. Raw material pretreatment:

[0123] After pulverizing Salix salix stubble with a moisture content of 15-20% into small particles of 0.5-1 cm, adding tap water and stirring to obtain a biomass slurry with a moisture content of 65%;

[0124] 2. The first step acid hydrolysis reaction:

[0125] Put the above biomass slurry into the premixing tank, add formic acid solution with a mass percentage concentration of 10% into the tank, mix evenly, and send the slurry formic acid mixture into the first reactor with a plunger type high-pressure pump. The bottom of the reactor is fed with high-temperature and high-pressure steam to increase the temperature and pressure in the first reactor, and carry out the first step of acid hydrolysis reaction to obtain the first step to acid hydrolysis mixture, wherein the weight ratio of biomass slurry to formic acid solution 100:8, the temperature of the first step acid hydrolysis re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com