Coal tar whole-fraction hydrogenation method

A technology for coal tar and full distillate, applied in the field of coal chemical industry, can solve the problems of high operation cost, complex process, long process, etc., and achieve the effects of safe and stable operation, simple process and high product conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

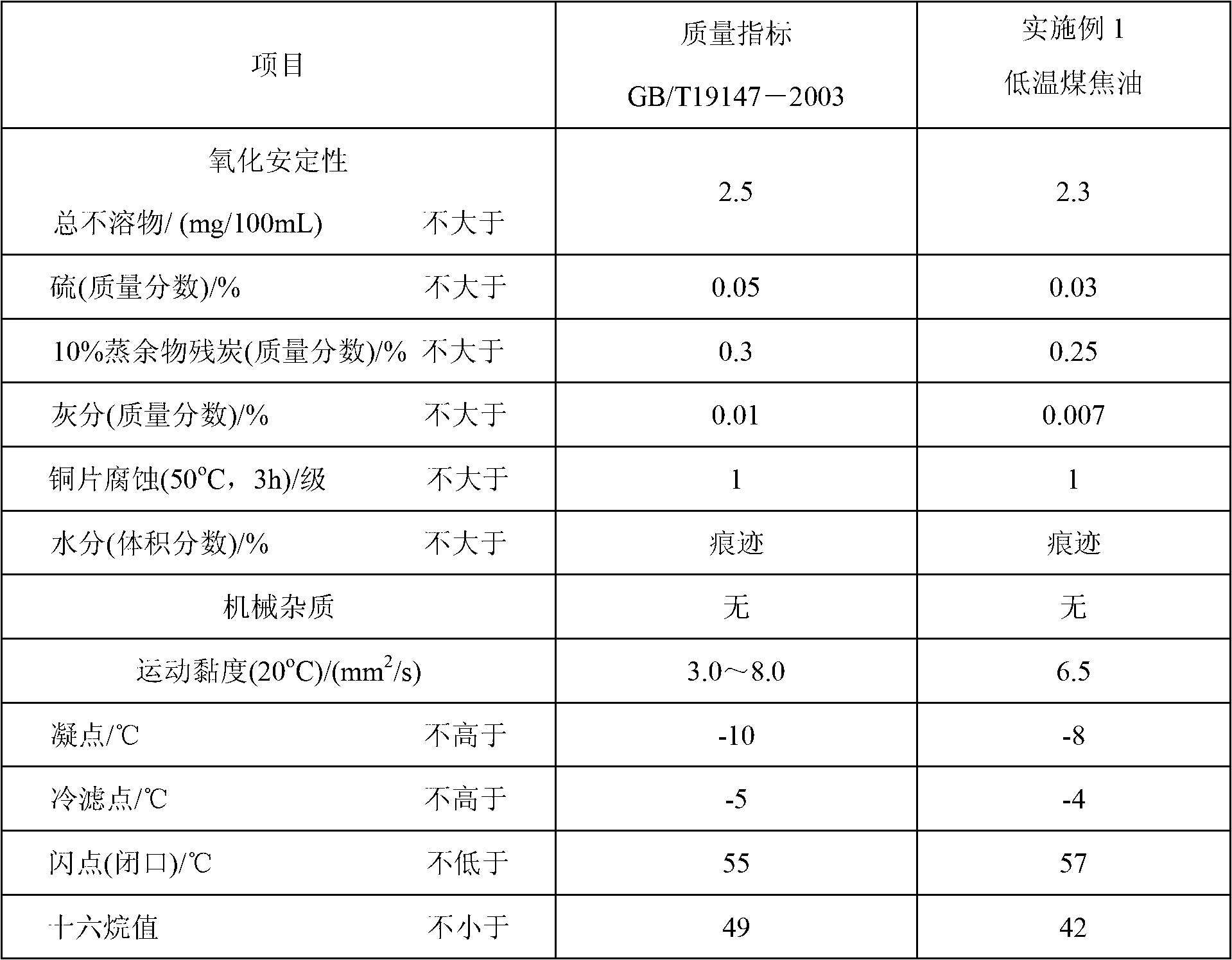

Embodiment 1

[0024] Taking 100L low-temperature coal tar as a raw material as an example, the method for hydrogenating the whole fraction of coal tar includes the following steps:

[0025] Step 1: Take 100L low-temperature coal tar and remove moisture, metals, and solid impurities in the purification device to complete the purification process of the whole fraction;

[0026] Step 2: Dissolve the purified coal tar and hydrogen in a hydrogen dissolving kettle under the conditions of 180°C, 5MPa, hydrogen-oil volume ratio of 1400:1, and hydrogen dissolving time of 25 minutes, so that the hydrogen can be fully dissolved in the coal tar. Obtain a liquid material with gas-liquid equilibrium;

[0027] Step 3: In the first trickle bed reactor, use RG-1 hydrogenation protection agent, FZC-200 type hydrodemetallization agent and RMS-1 type hydrodesulfurization agent in the first trickle bed reactor at 310°C , the pressure is 12MPa, the liquid volume space velocity is 1.3m 3 h -1 / m 3 1. The firs...

Embodiment 2

[0038] Taking 100L low-temperature coal tar as a raw material as an example, the method for hydrogenating the whole fraction of warm coal tar includes the following steps:

[0039] Step 1: Same as Example 1.

[0040]Step 2: Dissolve the purified coal tar and hydrogen in a hydrogen dissolving kettle under the conditions of 250°C, 3MPa, hydrogen-oil volume ratio 1800:1, and hydrogen dissolving time of 40 minutes to obtain a liquid material with gas-liquid balance;

[0041] Step 3: In the first trickle bed reactor, use RG-1 type hydrogenation protection agent, FZC-200 type hydrodemetallization agent and RMS-1 type hydrodesulfurization agent in the first trickle bed reactor to obtain the liquid material with gas-liquid balance. 360°C, pressure 9MPa, liquid volume space velocity 2.6m 3 h -1 / m 3 , the first catalytic hydrogenation reaction was carried out under the condition that the volume ratio of hydrogen to oil was 1800:1, the volume percentage of the RG-1 hydrogenation prot...

Embodiment 3

[0044] Taking 100L low-temperature coal tar as raw material as an example, the method for the hydrogenation of the whole fraction of coal tar comprises the following steps:

[0045] Step 1: Same as Example 1.

[0046] Step 2: Dissolve the purified coal tar and hydrogen in a hydrogen dissolving kettle at 150°C, 8MPa, hydrogen-oil volume ratio of 800:1, and hydrogen dissolving time of 15 minutes to obtain a liquid material with gas-liquid balance;

[0047] Step 3: In the first trickle bed reactor, use RG-1 type hydrogenation protection agent, FZC-200 type hydrodemetallization agent and RMS-1 type hydrodesulfurization agent in the first trickle bed reactor to obtain the liquid material with gas-liquid balance. 260℃, pressure 14MPa, liquid volume space velocity 0.28m 3 h -1 / m 3 , the first catalytic hydrogenation reaction was carried out under the condition that the volume ratio of hydrogen to oil was 900:1. The volume percentage of hydrogen demetallization agent is 10%, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com