Full-biodegradable material and preparation method thereof

A degradable material, whole biological technology, applied in the field of polymer compound composition, can solve the problems of low market recognition, performance gap, high price, etc., achieve good environmental benefits and social value, reduce costs, and low prices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

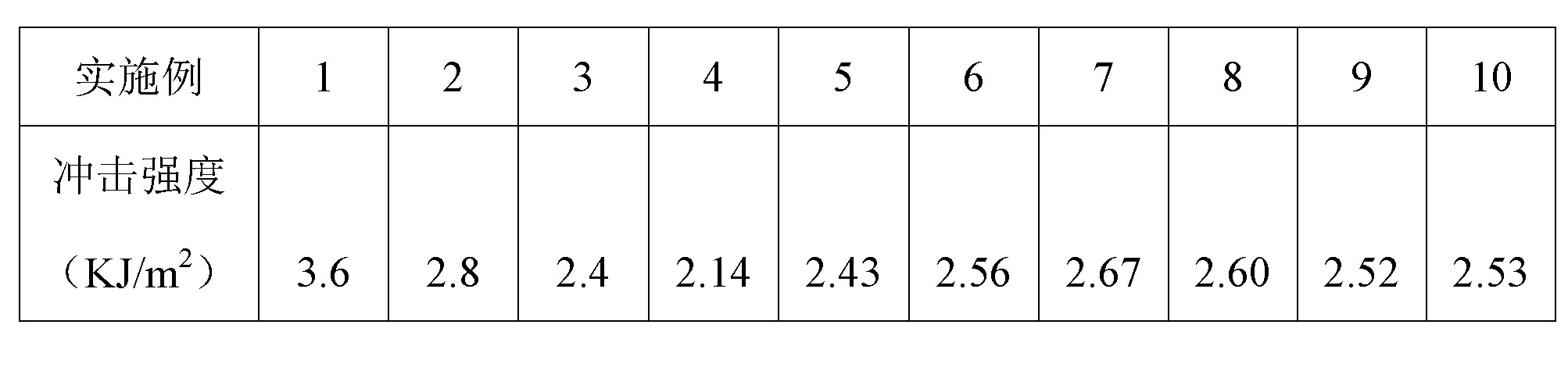

Examples

Embodiment 1

[0023] First, take the following raw materials by weight: 30 parts by weight of maleic anhydride grafted starch, 10 parts by weight of soybean oil, 35 parts by weight of polylactic acid, the copolymerization of butylene adipate and butylene terephthalate 10 parts by weight of the compound, 15 parts by weight of ethylene-vinyl acetate copolymer (EVA).

[0024] Then, the fully biodegradable material is prepared according to the following steps: mix all the above-mentioned raw materials uniformly to obtain a mixed material; then add the mixed material to a twin-screw extruder for melt blending (the mixed material passes through the temperature respectively at 130°C and 140°C , 150°C, 160°C, 170°C, 180°C, 170°C, 160°C for each melt blending interval) to form a material melt; the material melt is extruded from the die of the twin-screw extruder and then drawn, Cut into pellets to obtain material granules; after the material granules are dried, fully biodegradable materials are obta...

Embodiment 2

[0027] First, take the following raw materials by weight: 40 parts by weight of maleic anhydride grafted starch, 10 parts by weight of soybean oil, 25 parts by weight of polylactic acid, the copolymerization of butylene adipate and butylene terephthalate 10 parts by weight of the compound, 15 parts by weight of ethylene-vinyl acetate copolymer (EVA).

[0028] Then, the fully biodegradable material is prepared according to the following steps: mix all the above-mentioned raw materials uniformly to obtain a mixed material; then add the mixed material to a twin-screw extruder for melt blending (the mixed material passes through the temperature successively at 130°C, 140°C, 150°C, 160°C, 170°C, 180°C, 170°C, 160°C (melting and blending intervals) to form a material melt; the material melt is extruded from the die of the twin-screw extruder for drawing, cutting granules to obtain material granules; after material granules are dried, fully biodegradable materials are obtained. The ...

Embodiment 3

[0031] First, weigh the following raw materials by weight: 50 parts by weight of cornstarch, 8 parts by weight of palm oil, 2 parts by weight of linseed oil, 20 parts by weight of polylactic acid, butylene adipate and butylene terephthalate 12 parts by weight of the copolymer, 8 parts by weight of ethylene-vinyl acetate copolymer.

[0032] Then, the fully biodegradable material is prepared according to the following steps: mix all the above-mentioned raw materials uniformly to obtain a mixed material; then add the mixed material to a twin-screw extruder for melt blending (the mixed material passes through the temperature respectively at 130 ° C and 140 ° C , 150°C, 160°C, 170°C, 180°C, 170°C, 160°C for each melt blending interval) to form a material melt; the material melt is extruded from the die of the twin-screw extruder and then drawn, Cut into pellets to obtain material granules; after the material granules are dried, fully biodegradable materials are obtained. The twin-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com