Polyaspartic acid synthesized by microwave half-solvent method

A polyaspartic acid and solvent technology, applied in the field of polyaspartic acid synthesis, can solve the problems of difficult separation of solvent and product, low molecular weight of product, poor scale inhibition performance, etc. The effect of stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Specific embodiment one: the structural formula of the polyaspartic acid of the present embodiment is The range of p+q is 30-300. The optimum range of p+q in this embodiment is 30-100.

specific Embodiment approach 2

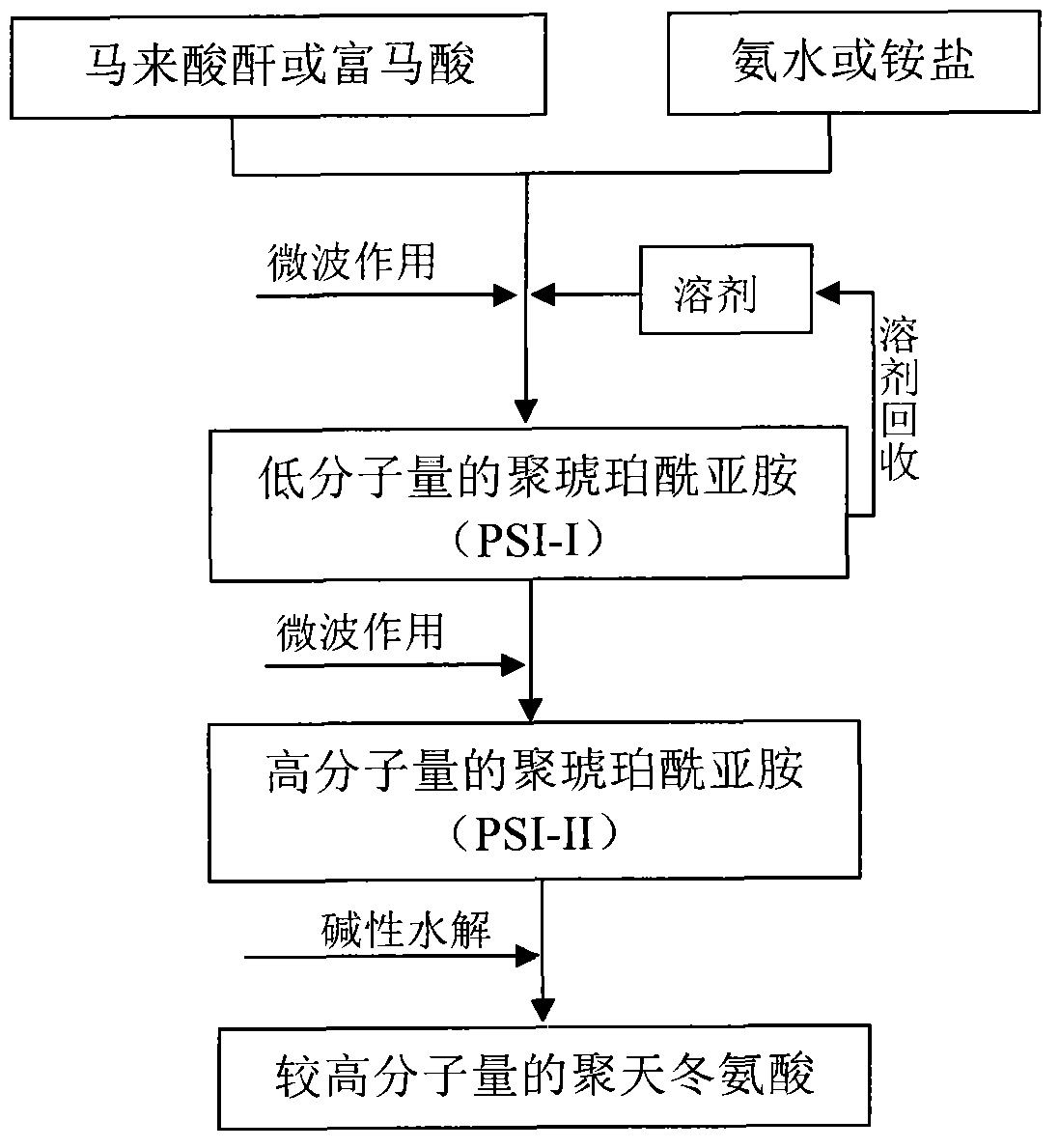

[0011] Specific embodiment two: this embodiment synthesizes polyaspartic acid according to the following steps: the synthesis process is divided into 2 steps, the first step is raw material with maleic anhydride or fumaric acid and ammonia or ammonium salt, wherein the ammonium salt is ammonium carbonate, Ammonium bicarbonate, ammonium sulfate, ammonium hydrogen sulfate, ammonium chloride, ammonium phosphate, ammonium hydrogen phosphate or diammonium hydrogen phosphate, the stoichiometric ratio of maleic anhydride or fumaric acid to ammonia water or ammonium salt is 0.01 to 99.9, Using microwave radiation, under the conditions of microwave frequency of 915±50MHz or 2450±50MHz and microwave power of 200~20000W, a small amount of solvent is added to the reactant, and the reaction is irradiated for 1~40min. During the reaction, all the solvent is recovered to obtain a small molecular weight The polysuccinimide (PSI-I), wherein the ratio of the stoichiometric number of the solvent ...

specific Embodiment approach 3

[0013] Specific embodiment three: add 20g maleic anhydride in the single mouthed round bottom flask, according to the stoichiometric number of maleic anhydride and ammonium bicarbonate acid is 1: 1.1, add 25ml dimethylformamide, microwave power is 800W radiation 3min, Afterwards, 1200W irradiated for 3 minutes to obtain a light brown fluffy product. At 3 minutes, all dimethylformamide was recovered, and 40 ml of 3mol / L NaOH was added to the product to dissolve the product. The pH of the solution was adjusted to be acidic, and the product was filtered. The filtrate was added to 250ml of absolute ethanol, the precipitate was collected, and vacuum-dried at 70°C to obtain polyaspartic acid, the calculated yield was 96.23%, and the weight-average molecular weight reached 4882. 3 The scale inhibition rate reaches 99.12%.

[0014] Specific embodiment four: add fumaric acid 20g in single-port round bottom flask, the ratio of fumaric acid and ammonium bicarbonate stoichiometric number ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com