Control system and method for improving acrylonitrile production stability

A control system, acrylonitrile technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of not being able to sense in time, affecting the stable operation of the recovery tower, and the temperature fluctuation of the sensitive plate, etc., to improve the operation. Stability, improve product purity and operational stability, reduce the effect of unstable fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] The following is an example of the mainstream 130,000-ton acrylonitrile plant in China. The acrylonitrile plant is controlled by the DCS control system in the central control room.

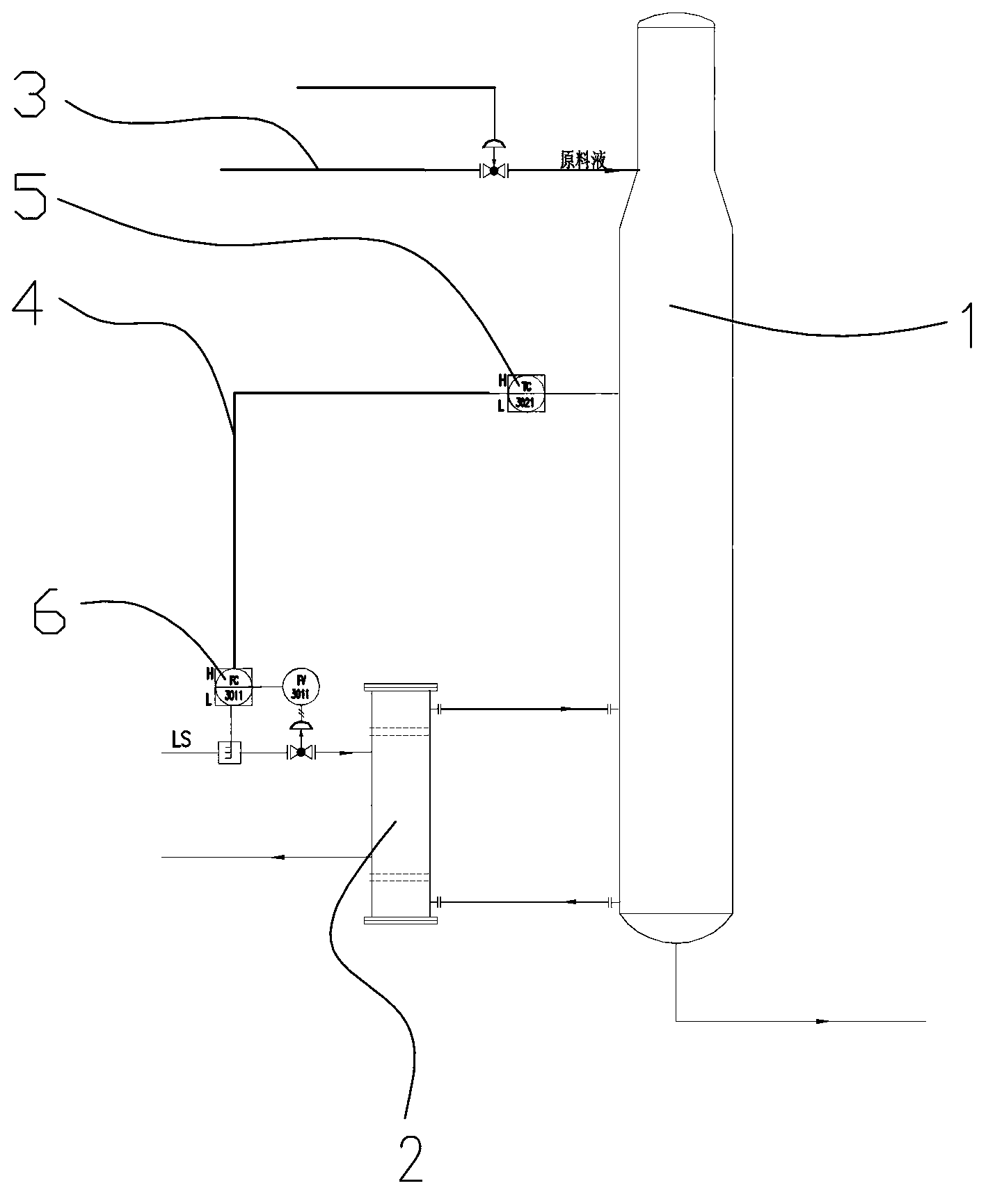

[0025] Such as figure 2 As shown, the recovery tower feed controller 7 is FC3012, the sensitive plate temperature controller 5 is TC3021, the reboiler flow controller 6 is FC3011, the calculation module 8 is TY3021, the steam regulating valve is FV3011, the above-mentioned controllers, automatic The regulating valve is connected to the DCS control system in the central control room of the acrylonitrile plant.

[0026] The recovery tower feed volume control loop 3 is connected to the recovery tower 1 and the absorption tower, and the still liquid of the absorption tower enters the recovery tower through the recovery tower feed volume control loop 3 as raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com