Environment-friendly bonding agent for ceramic sheet tape casting and preparation method of bonding agent

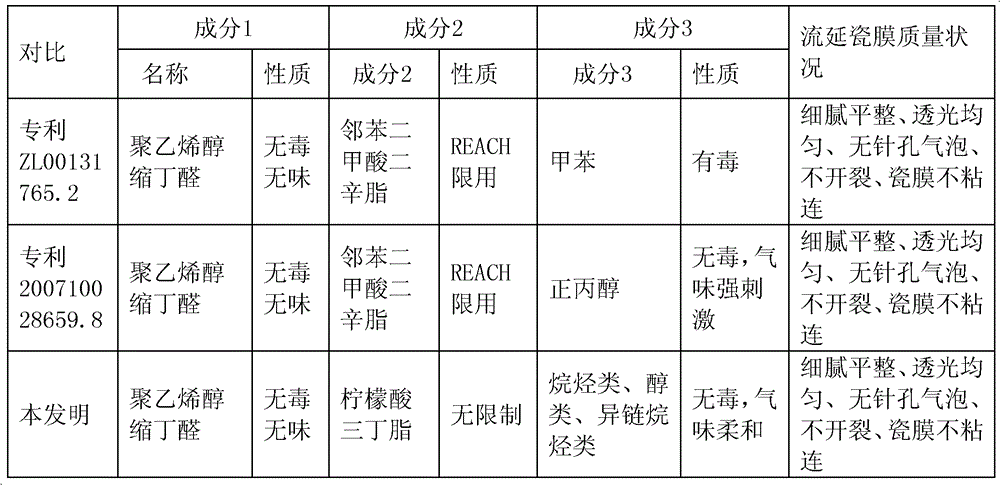

A technology of ceramic flakes and adhesives, which is applied in the manufacture of adhesives and the field of environmentally friendly adhesives. It can solve the problems of strong solvent volatilization, environmental pollution, stimulation, etc., and achieve the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Mix the Mobil Exxon isoparaffin ISOPAR E used as a solvent with ethanol at a ratio of 2:1, take 64 parts for later use, and then slowly add polyvinyl alcohol produced by German Waker Company as a high molecular polymer to the spare solvent 26 parts of butyral, stirring at the same time until the polyvinyl butyral resin is fully dispersed, then adding 10 parts of acetyl tributyl citrate as a plasticizer, stirring evenly, sealing and standing for 4 hours, then opening the cover and stirring until The resin is fully dissolved and becomes transparent. Seal and stand for defoaming for 8 hours. The obtained mixture is the environmental protection adhesive of the present invention.

Embodiment 2

[0017] Mix the Mobil Exxon isoparaffin ISOPAR E used as a solvent with ethanol at a ratio of 2:1, take 80 parts for later use, and then slowly add polyvinyl alcohol produced by German Waker Company as a high molecular polymer to the spare solvent 15 parts of butyral, stirring at the same time until the polyvinyl butyral resin is fully dispersed, then adding 5 parts of acetyl tributyl citrate as a plasticizer, stirring evenly, sealing and standing for 8 hours, then opening the cover and stirring until The resin is fully dissolved and becomes transparent. Seal and stand for defoaming for 15 hours. The obtained mixture is the environmental protection adhesive of the present invention.

Embodiment 3

[0019] Mix the Mobil Exxon isoparaffin ISOPAR E used as a solvent with isopropanol at a ratio of 1:1, take 56 parts for use, and then slowly add Polymer E from Solutia Company as a high molecular polymer to the spare solvent. 30 parts of vinyl butyral, while stirring until the polyvinyl butyral resin is fully dispersed, then add 12 parts of acetyl tributyl citrate as a plasticizer, 1 part of methyl siloxane, and 1 part of glyceride Stir evenly, seal and let stand for 6 hours, then open the cover and stir until the resin is fully dissolved and becomes transparent. Seal and stand for defoaming for 20 hours. The obtained mixture is the environmental protection adhesive of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com