Production process of ordinary electric rectifier diode chip

A rectifier diode and production process technology, which is applied to the production process field of ordinary power rectifier diode chips, can solve the problems of acid corrosion, poor chip thermal fatigue resistance, single variety, etc., achieves the ability to improve the working voltage, and solves the problem of thermal fatigue. , the effect of small on-state pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A production process of an improved ordinary power rectification diode chip comprises the following steps:

[0038] Step 1. The silicon single crystal diffuser is cut with a wire cutting machine, and cut into required regular circular geometric units.

[0039] Step 2. After the cutting is completed, the chip is thinned and cleaned to make the surface of the chip clean;

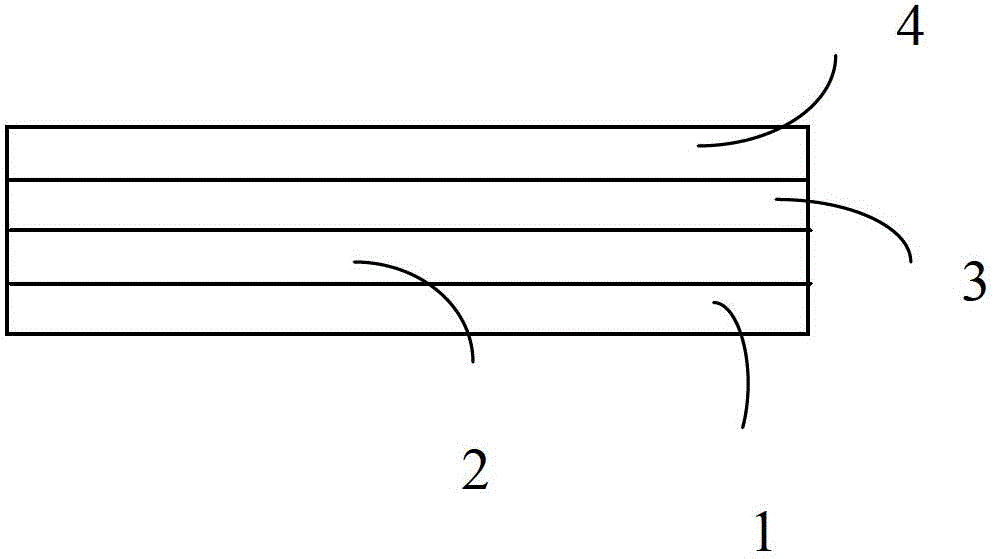

[0040] Step 3, chip press-fit layer structure, please refer to figure 1 As shown, vacuum sintering. After the chip is cleaned, follow the following multi-layer structure from bottom to top: molybdenum sheet 1, aluminum foil 2, single crystal silicon sheet 3, and vacuum sinter in a sintering furnace to form a molybdenum-aluminum-silicon phase alloy on the anode surface. The sintering temperature is between 660 degrees and 680 degrees, and the time is 30 minutes. Vacuum evaporation and vacuum microalloying, the aluminum film 4 is evaporated on the cathode surface of the entire single crystal silicon waf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com