Small NTC (Negative Temperature Coefficient) thermistor with glass-sealed diode structure and preparation method thereof

A technology of glass-encapsulated diodes and thermistors, applied in the direction of resistors, resistor parts, resistor terminals/electrodes, etc., can solve the problems of inability to use temperature sensors and meet the miniaturization of temperature measurement and sensor devices, and achieve easy batch production The effect of rapid production, low production cost, and small product size and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

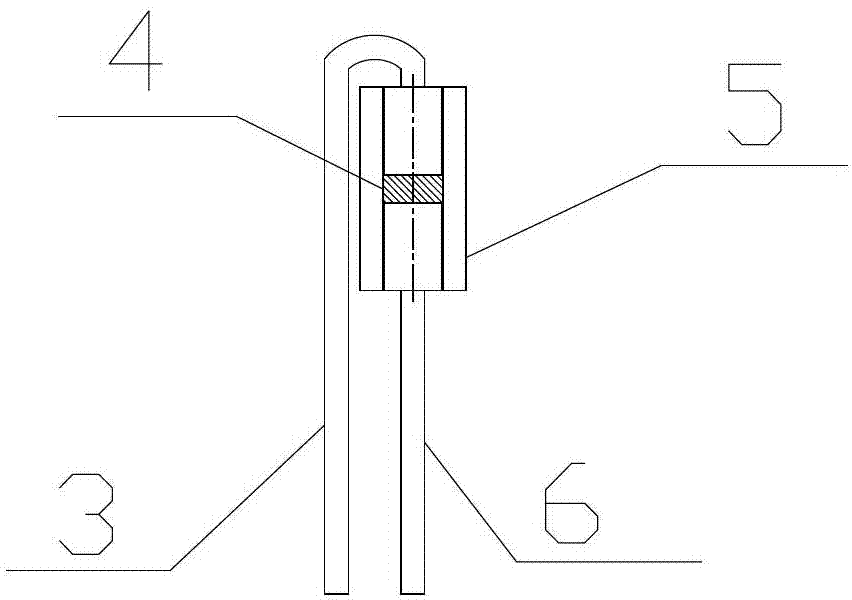

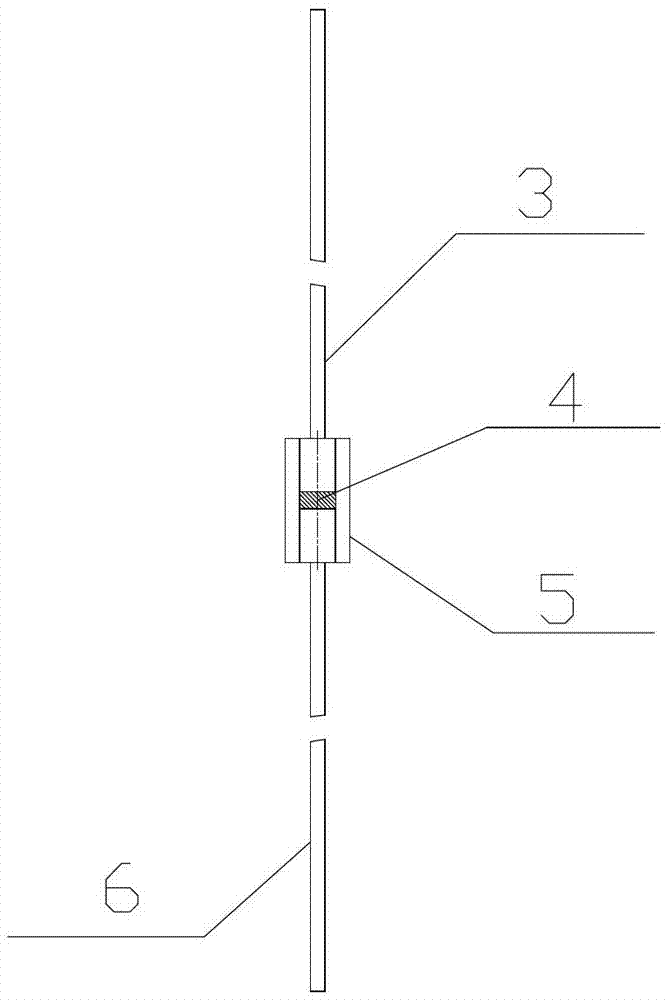

[0017] refer to figure 1 , The small glass-encapsulated diode structure NTC thermistor of the present invention is made of long and short Dumet wires 3,6, a glass bulb and a diode structure NTC thermal chip 4, the glass bulb 5 is 2.55mm long and has an outer diameter of 1.35mm. The long and short Dumet wires 3 and 6 are two identical Dumet wire electrode leads.

[0018] The concrete steps of preparation method of the present invention are as follows:

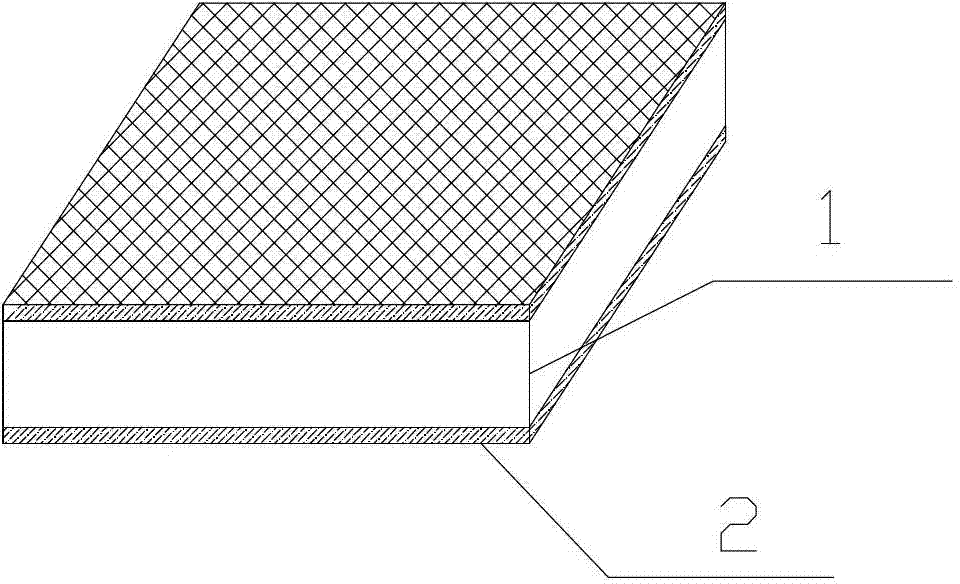

[0019] 1) Prepare NTC thermosensitive ceramics 1 by using transition metal oxides such as Mn, Co, Ni, Fe, Cu, etc. according to the electronic ceramic preparation process;

[0020] 2) Print the silver electrode paste onto the NTC heat-sensitive ceramic substrate through screen printing, burn in at 850°C for 10-15 minutes, and cover the upper and lower surfaces of the ceramic substrate with a layer of silver electrode 2 with a thickness of 8-15 μm;

[0021] 3) Cut the NTC thermosensitive electrode sheet 2 into 0.35-0.45mm squar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermistor | aaaaa | aaaaa |

| Thermistor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com