Method for predicting temperature range of high-temperature alloy coating of segment of blading of gas turbine

A technology for high-temperature alloys and turbine blades, which is applied in the field of prediction of the life of high-temperature alloy coatings, and can solve problems such as oxidation failure of high-temperature alloy coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

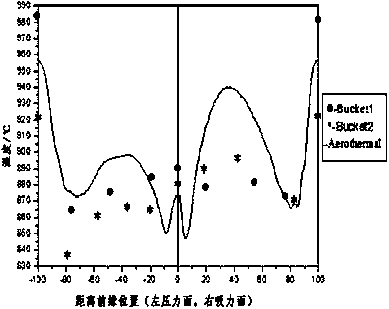

[0035] The operating history of the blade Bucket1, the total operating time is more than 30,500 hours, the heavy oil operation is more than 25,000 hours, the coating is repaired after 24,000 hours, the ignition is started 1,798 times, the blade is removed after service, and the surface is inspected macroscopically. Serious fouling was formed. After cleaning, it was found that there were ablation marks on the trailing edge of 50% to 60% of the blade body. In order to further analyze the structural changes of the coating and predict the temperature, destructive testing was carried out.

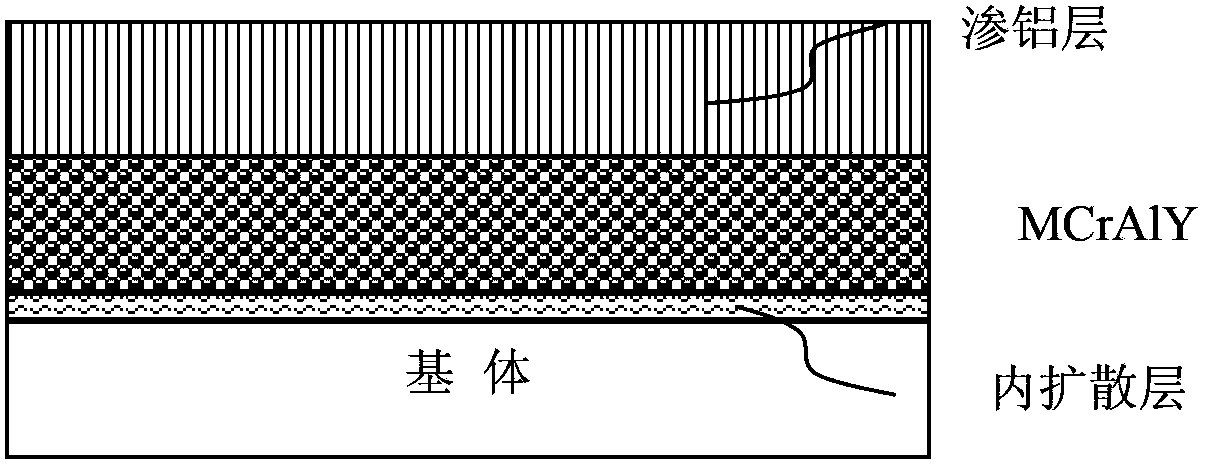

[0036] In order to protect the original appearance of the superalloy coating from being destroyed during the preparation process, the coating is protected by a mild electroless nickel plating method. After the nickel plating layer is deposited on the surface, the sample is hot-mounted, and the sample is polished, dried and carbon-sprayed after preparation. processing, backscattering observation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com