Hybrid textile cloth of aramid fiber and carbon fiber

A technology of aramid fiber and carbon fiber, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of easy damage, high cost and toughness, and achieve the effect of high impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

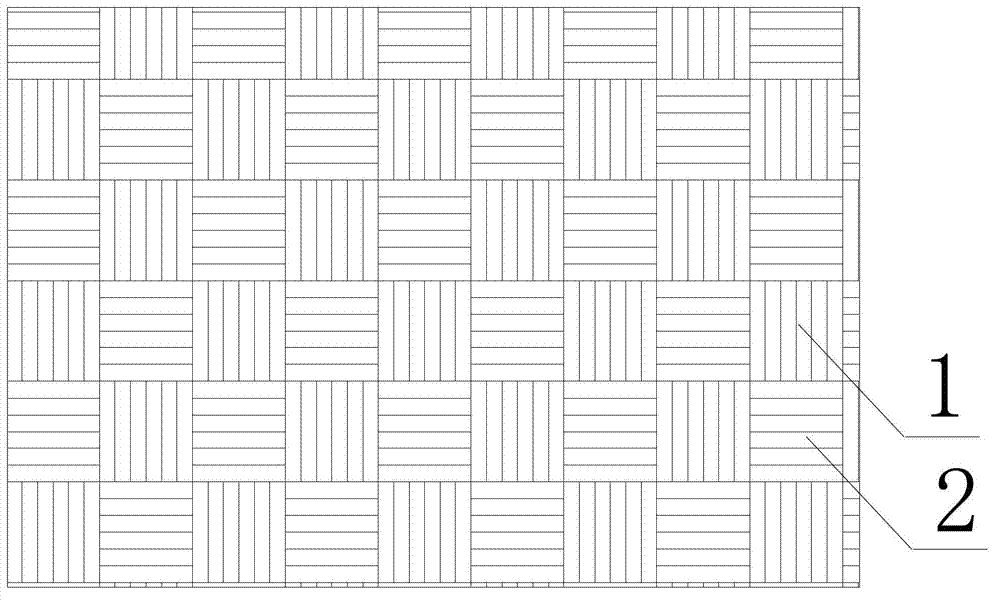

[0017] Such as figure 1 As shown, an aramid fiber and carbon fiber mixed cloth, it includes warp fiber bundle 1 and weft fiber bundle 2, the warp fiber bundle 1 is aramid fiber (or carbon fiber), and the weft fiber bundle 2 is carbon fiber (or aramid fiber), and the aramid fiber and carbon fiber are overlapped in sequence, and are arranged in a cross pattern.

[0018] The warp and weft density ratio of the aramid fibers and carbon fibers in the present invention is 1:1.

[0019] When implementing it:

[0020] The warp and weft of this product are made of large tow aramid fibers and carbon fibers arranged evenly in a 1:1 manner, and plain weave or twill weave is adopted. The main performance has both the rigidity of the steel plate and the flexibility of the body armor, and has a strong impact resistance. According to the design requirements and thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com