Method for enhancing chemical etching through femtosecond laser to manufacture large-scale micro-lens array

A technology of microlens array and femtosecond laser, applied in laser welding equipment, optics, lenses, etc., can solve the problems of low production efficiency, uncontrollable shape, high cost, etc., and achieve the effect of efficient processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

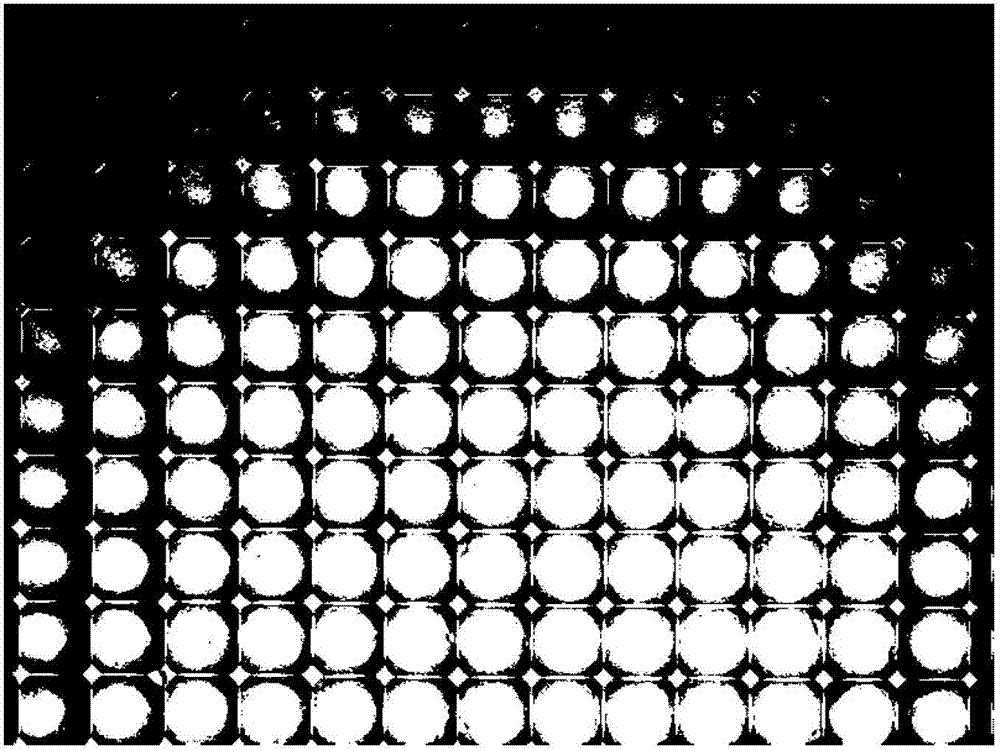

Image

Examples

Embodiment 1

[0026] A method for preparing a large-scale microlens array by using femtosecond laser enhanced chemical etching, comprising the following steps:

[0027] Step 1. Select the hard material used as the femtosecond laser target, put it into three solutions of acetone, ethanol, and deionized water in order to clean thoroughly, then place the target on the femtosecond laser micro-nano processing device, and select the pulse An ultrashort pulse laser with a width of 30fs and a wavelength of 800nm is focused on the surface of a hard material through an objective lens with a numerical aperture of 0.5;

[0028] Step 2. According to the shape of the rectangular microlens array to be processed, control the speed at which the precision machining platform moves the target. The femtosecond laser acts on the surface of the target for 500 pulses. Due to the special processing characteristics of the femtosecond laser, on the target A photodestructive zone is generated centered on the focus o...

Embodiment 2

[0034] A method for preparing a large-scale microlens array by using femtosecond laser enhanced chemical etching, comprising the following steps:

[0035] Step 1. Select the hard material used as the femtosecond laser target, put it into three solutions of acetone, ethanol, and deionized water in order to clean thoroughly, then place the target on the femtosecond laser micro-nano processing device, and select the pulse An ultrashort pulse laser with a width of 30fs and a wavelength of 800nm is focused on the surface of a hard material through an objective lens with a numerical aperture of 0.5;

[0036] Step 2. According to the shape of the rectangular microlens array to be processed, control the speed at which the precision machining platform moves the target. The femtosecond laser acts on the surface of the target for 500 pulses. Due to the special processing characteristics of the femtosecond laser, on the target A photodestructive zone is generated centered on the focus o...

Embodiment 3

[0042] A method for preparing a large-scale microlens array by using femtosecond laser enhanced chemical etching, comprising the following steps:

[0043] Step 1. Select the hard material used as the femtosecond laser target, put it into three solutions of acetone, ethanol, and deionized water in order to clean thoroughly, then place the target on the femtosecond laser micro-nano processing device, and select the pulse An ultrashort pulse laser with a width of 30fs and a wavelength of 800nm is focused on the surface of a hard material through an objective lens with a numerical aperture of 0.5;

[0044]Step 2. According to the shape of the rectangular microlens array to be processed, control the speed at which the precision machining platform moves the target. The femtosecond laser acts on the surface of the target for 1000 pulses. Due to the special processing characteristics of the femtosecond laser, on the target A photo-destructive zone is generated centered on the focus ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com