Manufacturing method of composite board seal head made from high-strength austenite nickel-iron-chromium alloy and austenite stainless steel

A technology of austenitic stainless steel and its manufacturing method, which can be applied to other home appliances, home appliances, applications, etc., to achieve the effects of improving plasticity, less impact, eliminating stress and softening the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

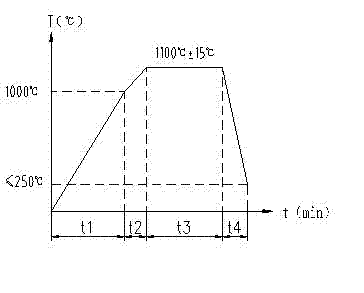

[0007] The following combination figure 1 The present invention will be described with specific embodiments. figure 1 Middle t1 is the heating time of the empty furnace before the head is put into the furnace; t2 is the heating time of the head with the furnace after being put into the furnace; t3 is the heat preservation time of the head in the furnace; t4 is the cooling time of the head in water after the head is out of the furnace; After the re-inspection is passed, the material is cut according to the size required by the process. The head plates that need to be spliced are spliced according to the process requirements. Various parameters and testing requirements must meet the process requirements. 100% PT inspection on spliced welds and plate surfaces, according to JB / T4730-2005 Class I qualification inspection; 100% UT inspection on the head round plate to ensure that the combination rate of the composite plate base layer ≥ 98%, and no single unbound area ≤ 20cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com