Solid-phase micro extraction fiber extraction head and preparation method thereof

A technology for extracting fibers and extraction heads, which is applied in the field of preparation of solid-phase microextraction-coated fibers, can solve the problems of poor compatibility of biological samples, low selectivity, and few types of SPME coatings, and achieve small surface area and improved bonding volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In this implementation, the preparation of an ATP nucleic acid aptamer / porous polymer coated SPME extraction head is taken as an example to describe the present invention in detail, but this does not limit the protection scope of the present invention.

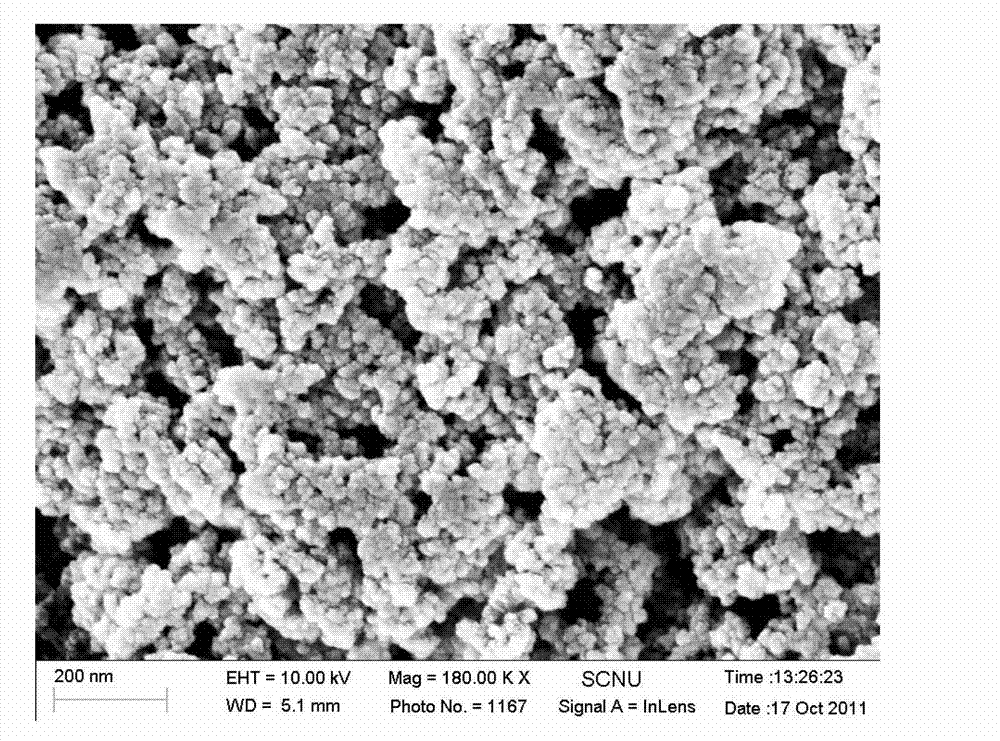

[0030] Such as figure 1 As shown, the preparation steps of the novel SPME extraction head of ATP nucleic acid aptamer / porous polymer coating are as follows:

[0031] (1) Take a bare quartz fiber with a diameter of 125 μm and a length of 6.0 cm, corrode it with 10% hydrofluoric acid solution for 20 seconds, rinse it with distilled water three times after taking it out; soak the fiber in 1.0 mol / L NaOH alkaline solution at room temperature for 0.5 h, rinse three times with distilled water after taking it out; soak the quartz fiber in 1.0mol / L HCl pickling solution for 0.5h after alkali washing, rinse it three times with distilled water after taking it out; put the quartz fiber in a petri dish and place it in an oven for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com