White LED (light-emitting diode) and method for packaging same

A white light and phosphor technology, applied in chemical instruments and methods, luminescent materials, sustainable buildings, etc., can solve the problems of low reliability of white light LEDs, difficult to meet LCD TVs, complicated process steps, etc., reducing the number of chips, connecting The effect of wire reduction, reduction of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

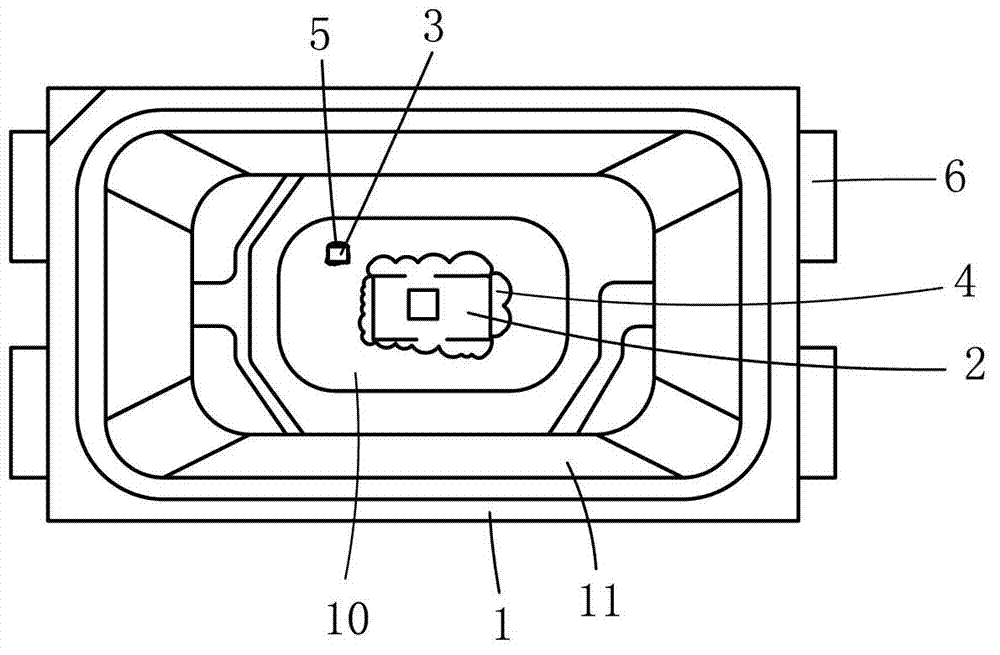

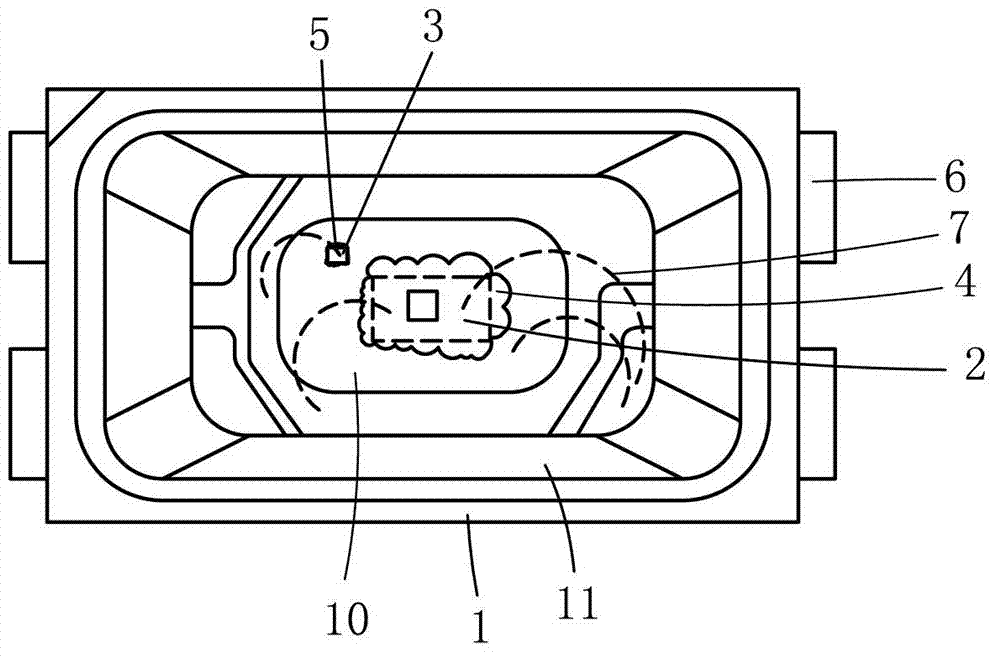

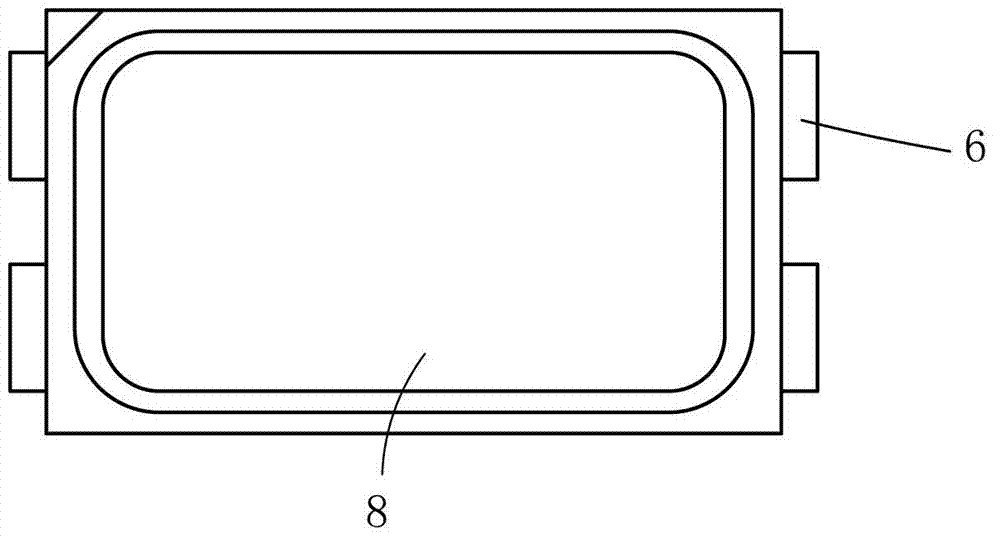

[0025] Such as figure 1 , figure 2 and image 3 Commonly shown, a white light LED, this white light LED is a SMD5630 lamp tube, including a bracket 1, the upper part of the bracket 1 is provided with a heat dissipation cup 11, the bottom of the heat dissipation cup 11 is provided with 10 and electrodes 6, and the copper block 10 is provided with a heat dissipation cup At the center of the bottom of 11, a blue light chip 2 is provided on the copper block 10, and a wire 7 is connected between the blue light chip 2 and the electrode 6. The wire 7 is a gold wire, and the inside of the cooling cup 11 is coated with fluorescent glue 8, which is Prepared from the following raw materials, TMR-200647-380490 phosphor (Shenzhen Tumeng Electromechanical Technology Co., Ltd.): silicate 05742 phosphor (Intemei Optoelectronics (Shenzhen) Co., Ltd.): silicate, nitride BLT-2500-AB Phosphor powder (Intemei Optoelectronics (Shenzhen) Co., Ltd.): Silica gel 6551AB (Dow Corning 6551 silica gel,...

Embodiment 2

[0037] Such asfigure 1 , figure 2 and image 3 Commonly shown, a white light LED, its structure is basically the same as that of Example 1, the difference is that TMR-200647-380490 fluorescent powder in fluorescent glue 8, silicate 05742 fluorescent powder, silicate, nitride BLT-2500 -The weight ratio of AB phosphor and silica gel 6551AB is: TMR-200647-380490 phosphor: silicate 05742 phosphor: silicate, nitride BLT-2500-AB phosphor: silica gel 6551AB=X:Y:Z :100, where X=0.4, Y=2, Z=5.

Embodiment 3

[0039] Such as figure 1 , figure 2 and image 3 Commonly shown, a white light LED, its structure is basically the same as that of Example 1, the difference is that TMR-200647-380490 fluorescent powder in fluorescent glue 8, silicate 05742 fluorescent powder, silicate, nitride BLT-2500 -The weight ratio of AB phosphor and silica gel 6551AB is: TMR-200647-380490 phosphor: silicate 05742 phosphor: silicate, nitride BLT-2500-AB phosphor: silica gel 6551AB=X:Y:Z :100, where X=0.4, Y=5, Z=2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com