High-viscosity poly alpha-olefin synthetic oil and preparation method thereof

A technology for olefin synthesis oil and olefin, which is applied in the production of liquid hydrocarbon mixture, petroleum industry, etc., can solve the problems that catalyst and product cannot be separated, catalyst is expensive, and product cost is high, and can reduce production cost, low molecular weight distribution, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

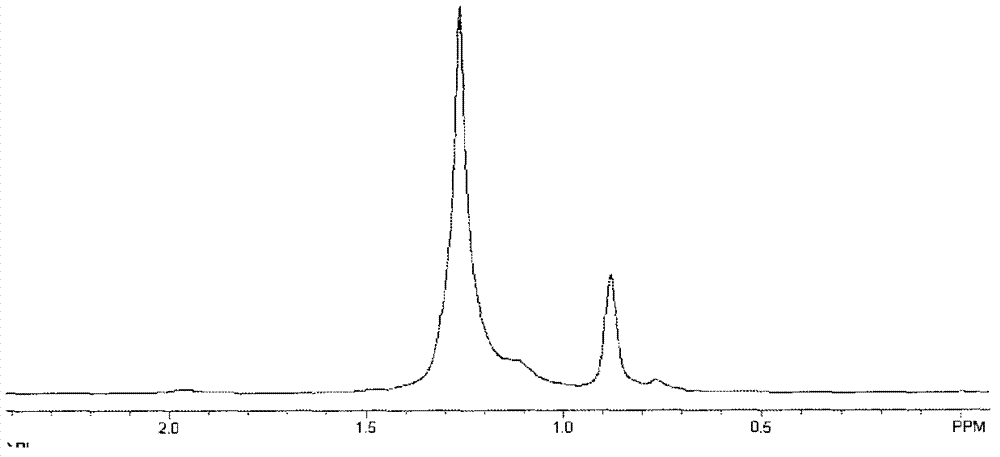

Image

Examples

Embodiment 1

[0044] Preparation of chloroaluminic acid 1-methyl-3-butylimidazole acidic ionic liquid:

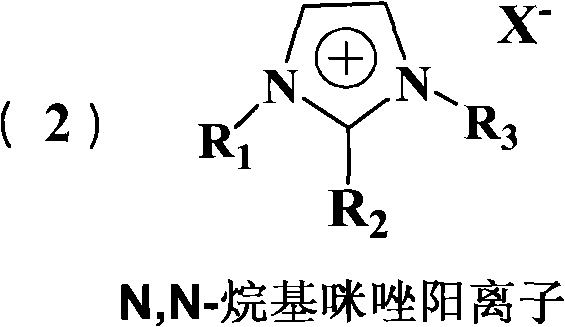

[0045] Add 40.0g of dry chlorinated 1-methyl-3-butylimidazolium salt into a 500ml round-bottomed flask, keep the temperature not higher than 80°C under nitrogen atmosphere, add 76.3g of aluminum trichloride to the round-bottomed flask in batches In the flask, the molar ratio of anions and cations is 2.5:1, kept under magnetic stirring for 12 hours, and stored under dry conditions for later use. The molecular structure of the ionic liquid is shown in formula (4), and it is called chloroaluminate chlorinated 1-methyl-3-butylimidazolium ionic liquid.

[0046] Formula (4)

Embodiment 2

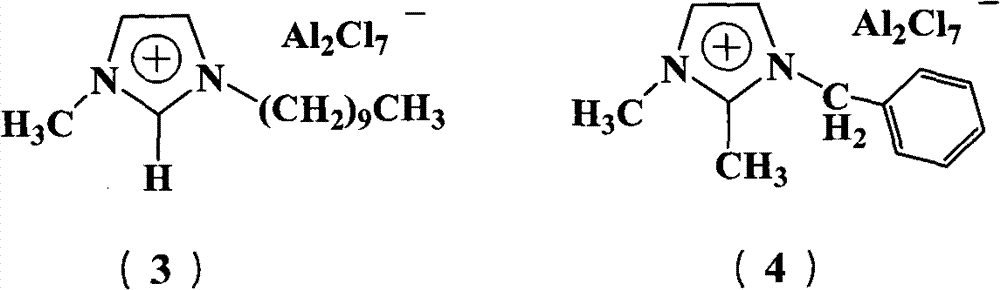

[0048] Preparation of 1-methyl-3-benzylimidazole acidic ionic liquid of chloroaluminate:

[0049] Add 40.0g of dry 1-methyl-3-benzyl imidazole chloride to a 500ml round bottom flask, keep the temperature not higher than 80°C under nitrogen atmosphere, add 30.7g of aluminum trichloride to the round bottom flask in batches In this method, the molar ratio of anion and cation was 1.2:1, kept under magnetic stirring for 12 hours, and stored under dry conditions for later use. The molecular structure of the ionic liquid is shown in formula (5), and it is called chloroaluminate 1-methyl-3-benzyl imidazolium ionic liquid.

[0050] Formula (5)

Embodiment 3

[0053] Weigh 0.2 g of the ionic liquid in Example 1 and add it to a 250 ml three-necked round-bottomed flask, put the round-bottomed flask into a low-temperature reaction bath, keep the temperature at 0° C., pass nitrogen gas to maintain an inert atmosphere, and stir mechanically. Weigh 40g of 1-decene and add it into the feeding tube so that the weight ratio of α-olefin to ionic liquid is 200:1, and keep a constant dropping rate into the flask. After reacting for 180min, the three-neck flask is allowed to stand for stratification and separated. Take out the upper layer polymer, add 1% NaOH aqueous solution to inactivate the ionic liquid remaining in the polymer, wash the polymer product with water, analyze its composition with GPC after drying, and then remove the unreacted monomer and dimer by distillation under reduced pressure , and then hydrogenated to obtain a colorless and transparent poly-alpha-olefin synthetic oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com