Scale removing agent applicable to alkaline-surfactant-polymer flooding and scale removing and unfreezing process

A ternary compound and scale removal technology, which can be used in cleaning appliances, drilling compositions, wellbore/well components, etc., can solve problems such as poor effect, and achieve obvious economic benefits, fast scale dissolution speed, and obvious blockage removal. The effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 9g of hydrochloric acid, 1g of hydrofluoric acid, 2g of glacial acetic acid, 1.0g of corrosion inhibitor, 0.5g of triethanolamine, 2.0g of ammonium chloride, 0.2g of alkylphenol polyoxyethylene ether and 84.3g of water to prepare a descaling agent .

Embodiment 2

[0027] Weigh 10g of hydrochloric acid, 2g of hydrofluoric acid, 2g of glacial acetic acid, 1.0g of corrosion inhibitor, 1.0g of triethanolamine, 2.0g of ammonium chloride, 0.2g of alkylphenol polyoxyethylene ether and 81.8g of water to prepare a descaling agent .

Embodiment 3

[0029] Weigh 9.6g of hydrochloric acid, 1.4g of hydrofluoric acid, 2g of glacial acetic acid, 1.0g of corrosion inhibitor, 0.7g of triethanolamine, 2.0g of ammonium chloride, 0.2g of alkylphenol polyoxyethylene ether and 83.1g of water and mix to prepare a clear solution. detergent.

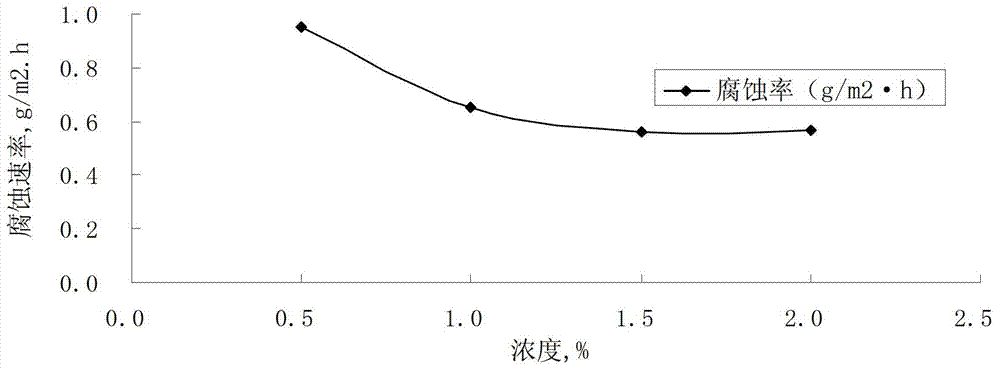

[0030] Performance evaluation of the scale remover suitable for weak alkali ASP flooding:

[0031] ⑴Scale dissolving performance

[0032] At the temperature of the reservoir, the dissolution rate of the scale remover to the scale samples in weak alkali oil wells can reach more than 95%.

[0033] Table 1 Scale-dissolving effect of scale remover on ternary oil well scale samples

[0034]

[0035] ⑵Scale removal effect

[0036] Using scanning electron microscope to observe the characteristics of the scale slices before soaking in the penetrant solution and after soaking for 24 hours, and intuitively describe the stripping effect of the penetrant. Such as figure 1 , figure 2 shown.

[0037...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com