Airflow centrifugal classification device for flake metal fine powder and ultrafine particles and debris

A technology of metal micropowder and centrifugal classification, which is applied in centrifuges and other directions, to achieve the effects of good product quality consistency, high production efficiency, and high scale rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

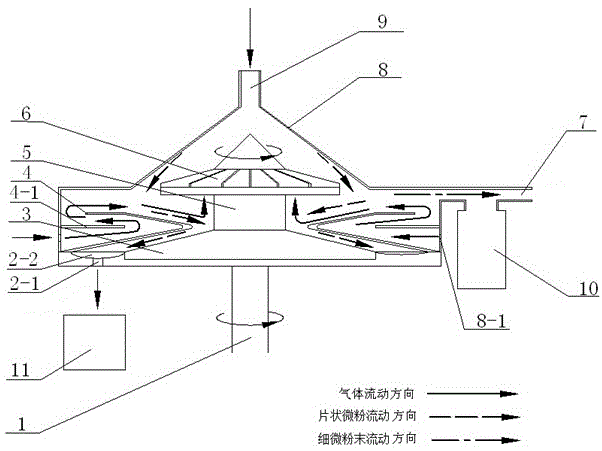

[0013] Embodiment: a kind of air flow centrifugal classification device of flake metal micropowder and extremely fine particles, debris, such as figure 1 As shown, it includes main shaft 1, discharge chute 2-2, finished product outlet 2-1, base 3, air intake guide plate 4, annular damping plate 4-1, shaft sleeve 5, leaf dust removal pipe 7, cover body 8 , air inlet 8-1, feed inlet 9, fine powder collector 10, finished product collector 11 and the swirling chamber; The top of 8 is feed inlet 9. The base and the bushing 5 are set on the main shaft 1, and the main shaft 1 passes through the center of the revolving cavity to drive the impeller 6 to rotate at high speed in the cover body 8. Along the rotating surface of the impeller 6, a dust removal pipeline 7 connected to the dust collector is opened at a place on the side wall of the whirling chamber, and one section of the dust removal pipeline 7 is connected to the fine powder dust collector. A discharge trough 2-2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com