Flotation method for improving recovery value of gold and silver in lead-zinc-gold and silver ore

A gold-silver, lead-zinc technology, applied in the field of flotation to improve the recovery value of gold and silver in lead-zinc gold-silver mines, can solve the problems of high gold content in zinc concentrates, achieve good gold and silver inhibition, and increase the recovery value of gold and silver Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

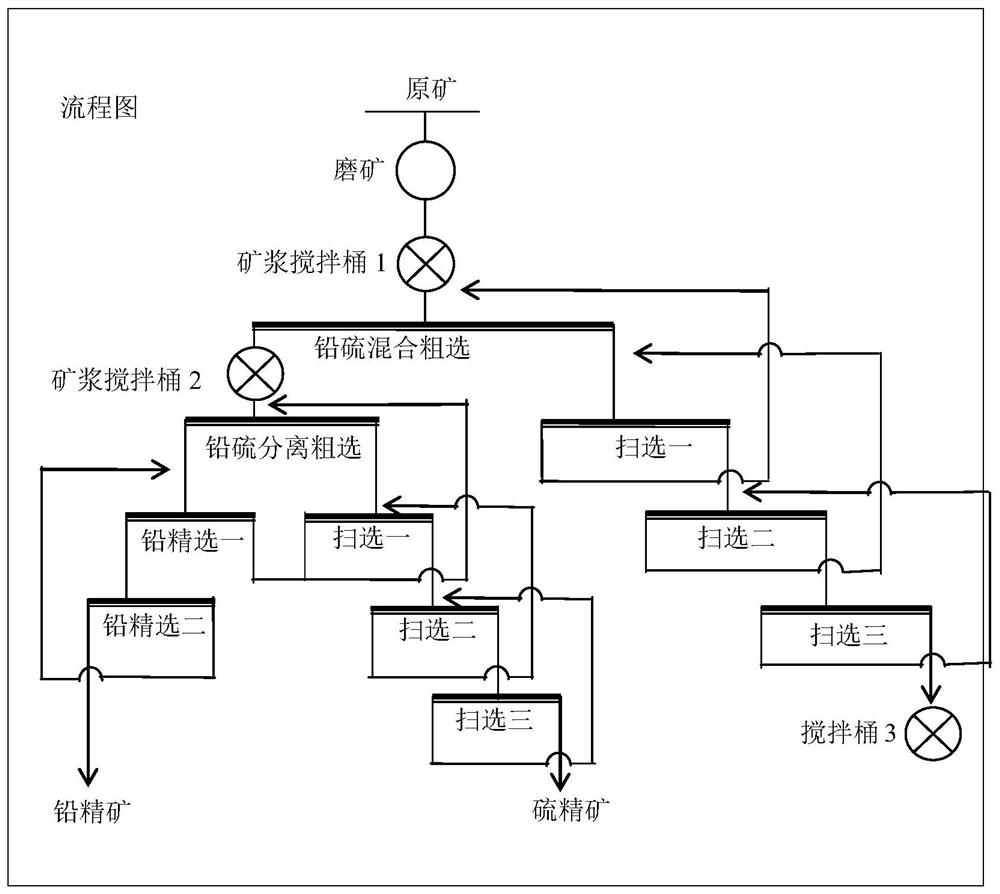

[0024] Such as figure 1 As shown, a flotation method for improving the recovery value of gold and silver in lead-zinc gold-silver ore: the lead-zinc raw ore is ground and classified, and the overflow of the classifier enters the slurry mixing tank 1.

[0025] Add 400-1000g / t of zinc sulfate, 50-200g / t of lead collector HQ77, and 50-150g / t of ethyl xanthate into the pulp mixing tank 1.

[0026] The ore slurry in the mixing tank 1 enters the lead-sulfur mixed roughing flotation tank, the tailings from the lead-sulfur mixed roughing go into the first lead-sulfur mixed scavenging flotation tank, and the concentrate obtained from the lead-sulfur mixed roughing goes into the slurry mixing tank 2. Add sodium humate 100-600g / t, sodium sulfite 200-800g / t and lead collector HQ77 10-50g / t in the slurry mixing tank 2.

[0027] The pulp in the slurry mixing tank 2 enters the lead-sulfur separation roughing flotation cell, the concentrate obtained by the lead-sulfur separation roughing goe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com