Hydrophilic epoxy resin binder and preparation method and application thereof

An epoxy resin and adhesive technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of large amount of resin, low wet compressive strength of water-permeable products, etc., to improve mechanical properties and durability properties, reducing groundwater pollution, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

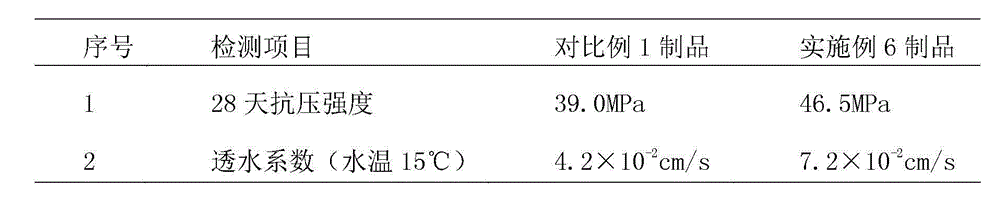

Examples

Embodiment 1

[0033] Accurately weigh raw materials (Kg): bisphenol A epoxy resin E-44 is 750, surfactant Span S-80 is 60, surfactant Tween T-80 is 60, catalyst tetraethylammonium chloride is 0.003.

[0034] Preparation:

[0035] The preparation method of this hydrophilic epoxy resin adhesive is made up of the following steps:

[0036] (a) Add bisphenol A type epoxy resin into the reaction device and stir;

[0037] (b) According to the amount of epoxy groups in the bisphenol A epoxy resin, add the surfactant Span and the surfactant Tween, and stir for 15-30 minutes;

[0038] (c) Add the catalyst, stir for 15-30 minutes, and heat up to 70-120°C;

[0039] (d) Control the temperature in the reaction device between 70-120°C to carry out the reaction;

[0040] (e) Sampling and testing, the epoxy value is measured according to the hydrochloric acid-acetone method, when the epoxy value reaches the theoretical value of the reaction, the system cools down;

[0041] (f) After the reaction is com...

Embodiment 2

[0044] Accurately weigh raw materials (Kg):

[0045] The bisphenol A type epoxy resin E-44 is 650, the surfactant Span S-60 is 50, the surfactant Tween T-60 is 50, and the catalyst 2-methylimidazole is 0.002.

[0046] Preparation:

[0047] The preparation method of this hydrophilic epoxy resin adhesive is made up of the following steps:

[0048] (a) Add bisphenol A type epoxy resin into the reaction device and stir;

[0049] (b) According to the amount of epoxy groups in the bisphenol A epoxy resin, add the surfactant Span and the surfactant Tween, and stir for 15-30 minutes;

[0050] (c) Add the catalyst, stir for 15-30 minutes, and heat up to 70-120°C;

[0051] (d) Control the temperature in the reaction device between 70-120°C to carry out the reaction;

[0052] (e) Sampling and testing, the epoxy value is measured according to the hydrochloric acid-acetone method, when the epoxy value reaches the theoretical value of the reaction, the system cools down;

[0053] (f) A...

Embodiment 3

[0056] Accurately weigh raw materials (Kg):

[0057] Bisphenol A type epoxy resin E-35 850, surfactant Span S-40 100, surfactant Tween T-60 100, catalyst benzyl triethylammonium chloride 0.004.

[0058] Preparation:

[0059] The preparation method of this hydrophilic epoxy resin adhesive is made up of the following steps:

[0060] (a) Add bisphenol A type epoxy resin into the reaction device and stir;

[0061] (b) According to the amount of epoxy groups in the bisphenol A epoxy resin, add the surfactant Span and the surfactant Tween, and stir for 15-30 minutes;

[0062] (c) Add the catalyst, stir for 15-30 minutes, and heat up to 70-120°C;

[0063] (d) Control the temperature in the reaction device between 70-120°C to carry out the reaction;

[0064] (e) Sampling and testing, the epoxy value is measured according to the hydrochloric acid-acetone method, when the epoxy value reaches the theoretical value of the reaction, the system cools down;

[0065] (f) After the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com