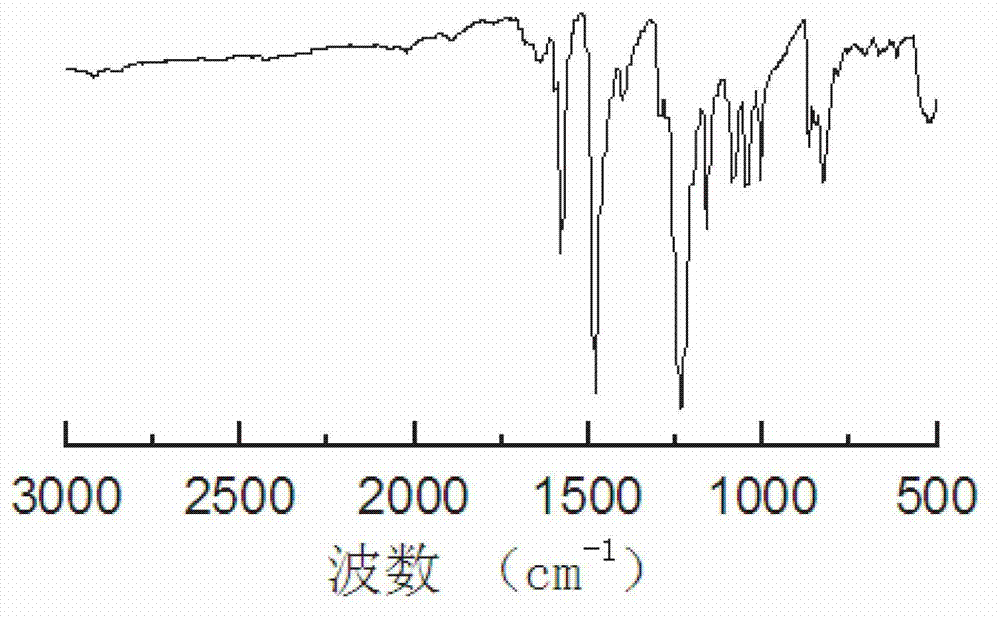

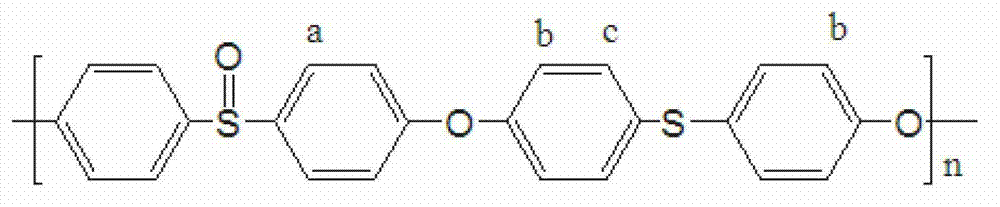

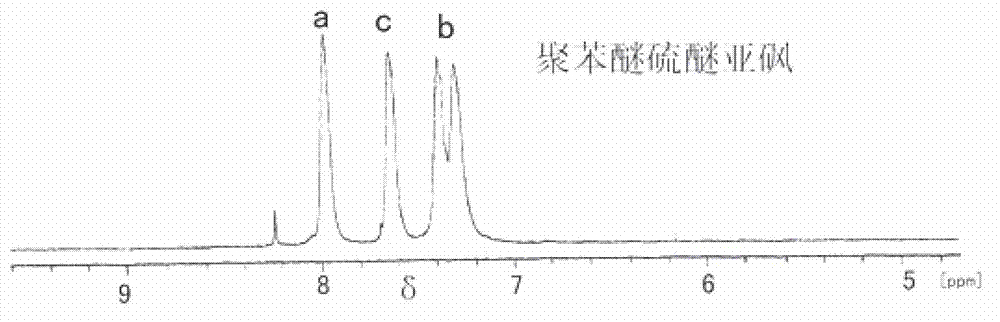

Polyphenyl ether thioether sulfoxide and preparation method thereof

A technology of polyphenylene ether and dihalodiphenyl sulfoxide, which is applied in the field of polyphenylene ether sulfide sulfoxide and its preparation, can solve problems such as difficult to meet, and achieve the effects of simplified process, high yield, and good solution processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Raw material and its formula

[0039] 4,4′-dihydroxydiphenyl sulfide 65.4g (0.30mol)

[0040] 4,4'-Difluorodiphenylsulfoxide 71.4g (0.30mol)

[0041] Anhydrous potassium carbonate 37.1g (0.35mol)

[0042] Sodium formate 5.9g (0.086mol)

[0043] Copper powder 2.2g (0.034mol)

[0044] N,N'-Dimethylacetamide 600mL

[0045] Xylene 100mL;

[0046] 2. The process steps are as follows:

[0047] (1) Polymerization reaction

[0048] Under the protection of nitrogen, the reaction monomer 4,4'-dihydroxydiphenylsulfide, 4,4'-difluorodiphenylsulfoxide, anhydrous potassium carbonate, sodium formate, copper powder, N, Add N'-dimethylacetamide and xylene into the reaction kettle and stir, heat and dehydrate at a heating rate of 0.6°C / min, complete dehydration when the temperature reaches 140°C, and then heat up to 170°C for polymerization reaction, reaction The time is 24 hours, when the reaction finishes, stop stirring after naturally cooling to room temperature;

[0049] ...

Embodiment 2

[0055] 1. Raw material and its formula

[0056] 4,4′-dihydroxydiphenyl sulfide 64.10g (0.294mol)

[0057] 4,4'-Difluorodiphenylsulfoxide 71.4g (0.30mol)

[0058] Anhydrous sodium carbonate 37.1g (0.35mol)

[0059] Trisodium phosphate 8.2g (0.03mol)

[0060] Cuprous oxide 4.3g (0.03mol)

[0061] Sulfolane 500mL

[0062] Xylene 140mL;

[0063] 2. The process steps are as follows:

[0064] (1) Polymerization reaction

[0065] Under the protection of nitrogen, the reaction monomer 4,4'-dihydroxydiphenyl sulfide, 4,4'-difluorodiphenyl sulfoxide, anhydrous sodium carbonate, trisodium phosphate, cuprous oxide , sulfolane and xylene are added to the reaction kettle and stirred, heated and dehydrated at a heating rate of 0.5°C / min. When the temperature reaches 140°C, the dehydration is completed, and then the temperature is raised to 220°C for polymerization. The reaction time is 6 hours. Reaction finishes, stops stirring after naturally cooling to room temperature;

[0066] (...

Embodiment 3

[0069] 1. Raw material and its formula

[0070] 4,4′-dihydroxydiphenyl sulfide 64.75g (0.297mol)

[0071] 4,4'-Difluorodiphenylsulfoxide 71.4g (0.30mol)

[0072] Anhydrous sodium hydroxide 30g (0.75mol)

[0073] Sodium p-toluenesulfonate 9.7g (0.05mol)

[0074] Cuprous oxide 5.8g (0.04mol)

[0075] Hexamethylphosphoric triamide 450mL

[0076] Toluene 120mL;

[0077] 2. The process steps are as follows:

[0078] (1) Polymerization reaction

[0079] Under the protection of nitrogen, the reaction monomer 4,4'-dihydroxydiphenylsulfide, 4,4'-difluorodiphenylsulfoxide, anhydrous sodium hydroxide, sodium p-toluenesulfonate, Add cuprous oxide, hexamethylphosphoric triamide and toluene into the reaction kettle and stir, heat and dehydrate at a heating rate of 0.6°C / min, complete dehydration when the temperature reaches 130°C, and then heat up to 200°C for polymerization , the reaction time is 14 hours, when the reaction ends, stop stirring after naturally cooling to room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com