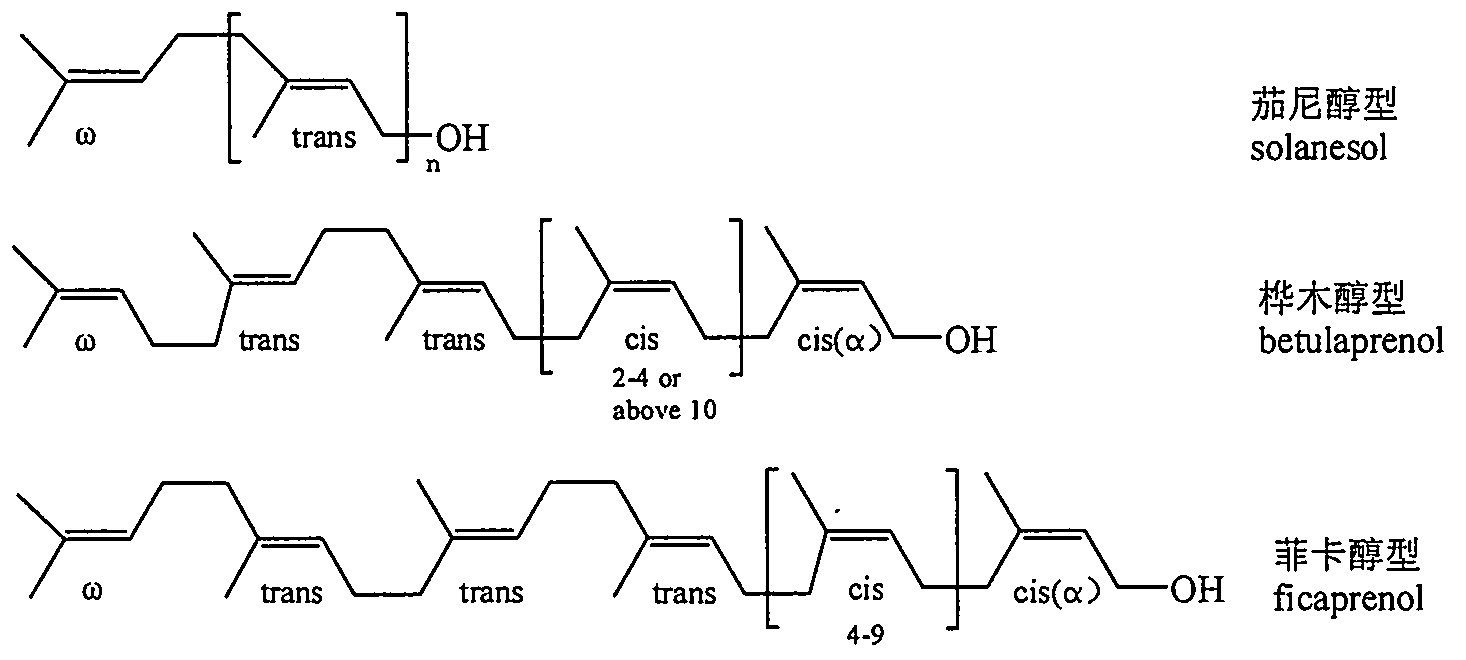

A kind of preparation method of plant polyprenol and its hydrogenated derivatives with antibacterial and antioxidative activity

An antioxidant activity, polyprenol technology, applied in the field of biomedicine, can solve the problems of little research on antioxidant and bacteriostatic biological activity, and no report on purification and separation of polyprenol.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Preparation method of polyprenyl alcohol and its hydrogenated derivatives

[0040] A method for preparing plant polyprenol and its hydrogenated derivatives with antibacterial and antioxidative activities, comprising the following steps:

[0041] The first step, polyprenol lipid extraction: fresh plant leaves rich in polyprenol lipids, such as one of ginkgo leaves, pine needles, and mulberry leaves, preferably ginkgo leaves, are dried in the shade at room temperature and crushed to 100 For the powder below the mesh, add anhydrous acetone or any solvent in C1-C3 alcohol, preferably acetone; mix the leaves with the solvent at a mass ratio of 1:20, soak at room temperature for 10-72 hours, preferably 24-48 hours; or leaves After mixing with the solvent at a mass ratio of 1:20, extract by microwave or ultrasonic extraction at 10°C to 80°C for 10 to 60 minutes, preferably ultrasonic, at an extraction temperature of 10°C to 40°C, for 10 to 30 minutes, and repeat the ...

Embodiment 2

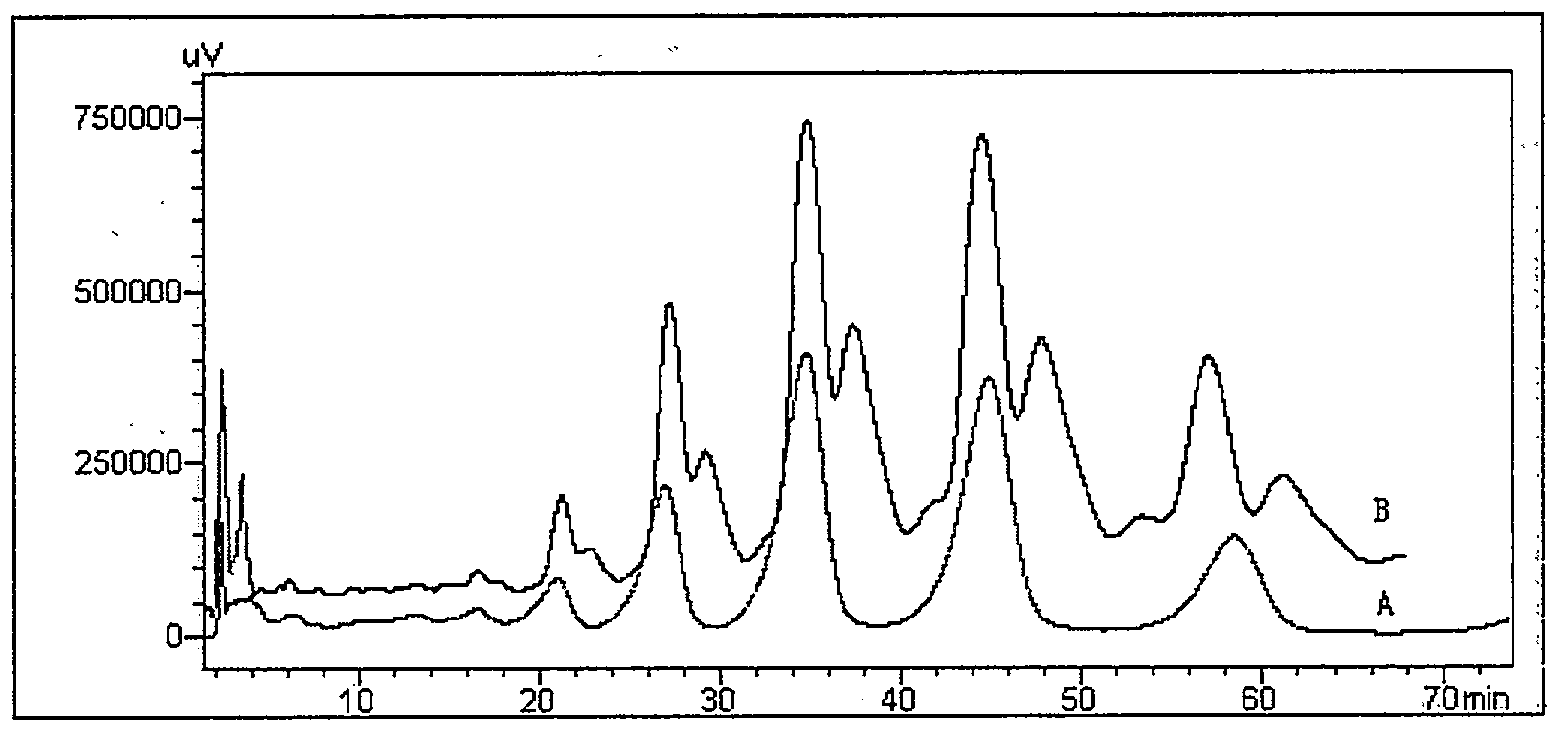

[0050] Embodiment 2 polyprenol hydrogenation reaction single factor test

[0051] 1. Selection of reaction time

[0052] The reaction temperature is fixed at 30°C, the solvent is dichloromethane:methanol=2:1 (V / V), and the catalyst is (S)-Ru(OAc) 2 (BINAP), the mass ratio of polyprenol and catalyst is 100:1, H pressure 10MPa, the reaction time is 3h, 6h, 9h, 12h, 18h, 24h, 36h, and the supernatant is taken for HPLC detection in the reaction process , and the reaction conversions were 6.8%, 16%, 22%, 32%, 41%, 56% and 58%, respectively. With the increase of the reaction time, the yield increases gradually and is basically stable after 24 hours, so the preferred reaction time is 24 hours.

[0053] 2. Selection of catalyst dosage

[0054] The reaction temperature is fixed at 20°C, and the catalyst is Ru(BINAP)(OAc) 2 , solvent dichloromethane:methanol=3:1(V / V), H 2 The pressure is 12MPa, the reaction time is 24h, the mass ratio of polyprenol to catalyst is 50:1, 100:1, 200:1...

Embodiment 3

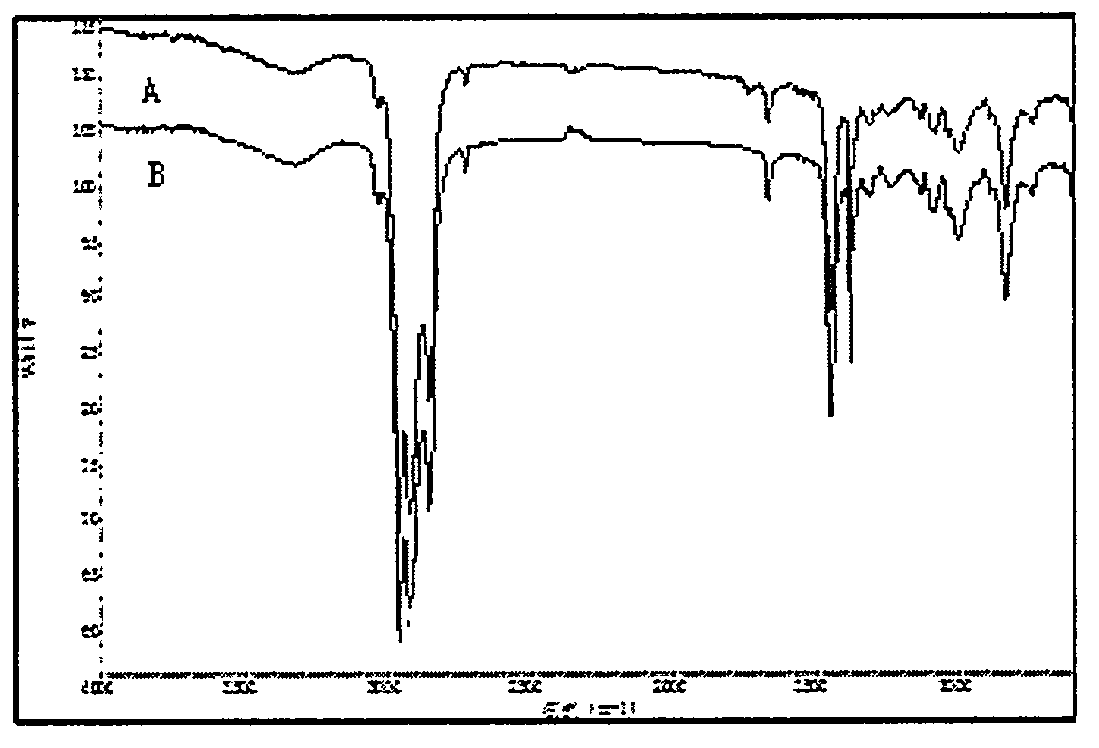

[0057] The purification experiment of embodiment 3 polyprenol

[0058] 1. Take 1 kg of mulberry leaves, crush them into 40-mesh powder, add 20 kg of anhydrous acetone, soak at room temperature for 50 hours, filter, then add 15 kg of anhydrous acetone, ultrasonically extract at 40°C for 20 minutes, combine the extracts, and recover the organic solvent in a vacuum , the concentrate is polyprenol lipid ointment;

[0059] 2. Four different types of adsorption carriers were screened, including silica gel, activated carbon for monosodium glutamate decolorization, polyamide resin, and attapulgite. Pure urea and the mass ratio of urea and adsorption carrier were 10:1, 5:1, 5:2, : 3, 1: 1 etc. 5 kinds of different mass ratios are carried out single-factor screening to the purification of polyprenol lipid ointment, and the results are shown in Table 1-2.

[0060] Table 1 Purification results of different proportions of urea silica gel

[0061]

[0062] From Table 1, using silica ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com