Lightweight acoustic panel containing rare earth catalyst, and preparation method thereof

A technology of rare earth catalysts and sound-absorbing panels, applied in chemical instruments and methods, physical/chemical process catalysts, ceramic products, etc. Low-level problems, to achieve the effects of light weight, accelerated preparation speed, and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

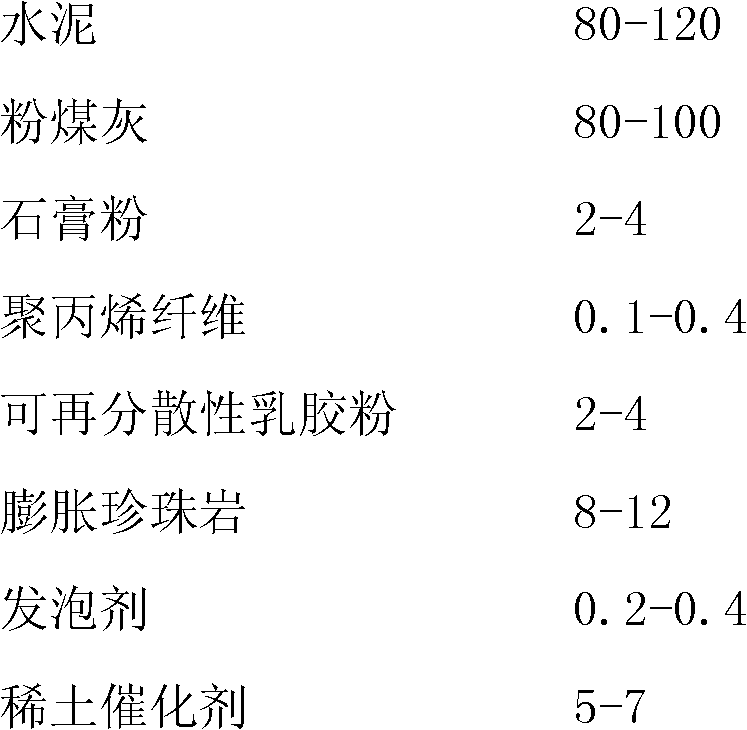

[0037] 1. Prepare materials according to the following proportions by weight

[0038]

[0039] Wherein, the cement is Portland cement with a label of 42.5R; the fly ash is purchased from the primary fly ash of Fuzhou Huaneng Thermal Power Plant; the polypropylene fiber is a monofilament polypropylene fiber, which The density is 0.91g / cm 3, its equivalent diameter is 18-48um; The redispersible latex powder is dispersible latex powder (produced by Shanxi Sanwei Group Co., Ltd., model: SWF-04) of VAC / VeoVa copolymerization, wherein solid content ≥ 98 %, the ash content is 8-12%, the bulk density is 300-500g, and the viscosity of 50% aqueous solution is 0.5-2.0Pa·s; the diameter of the expanded perlite is 1-3mm; the foaming agent is purchased from Jiangsu Qingting Detergent Co., Ltd.'s anionic surfactant foaming agent, the model is HF; the rare earth catalyst is lanthanum chloride.

[0040] 2. Prepare mortar

[0041] 1) Add expanded perlite to the mixer, start the mixer, the...

Embodiment 2

[0052] 1. Prepare materials according to the following proportions by weight

[0053]

[0054] Wherein, the cement is Portland cement with a label of 52.5R; the fly ash is purchased from the first-grade fly ash of Fuzhou Huaneng Power Plant; the polypropylene fiber is a monofilament polypropylene fiber, which The density is 0.85g / cm 3 , its equivalent diameter is 18-48um; Described redispersible latex powder is VAC / VeoVa copolymerized dispersible latex powder (produced by Shanxi Sanwei Group Co., Ltd., model: SWF-04), its 50% aqueous solution viscosity 0.5-2.0Pa·s; the foaming agent is purchased from Jiangsu Qingting Detergent Co., Ltd. anionic surfactant foaming agent, the model is HF; the rare earth catalyst is lanthanum chloride.

[0055] 2. Prepare mortar

[0056] 1) Add expanded perlite to the mixer, start the mixer, then add cement, fly ash, plaster of paris, polypropylene fiber, redispersible latex powder, rare earth catalyst, water in the stirring state, and stir ...

Embodiment 3

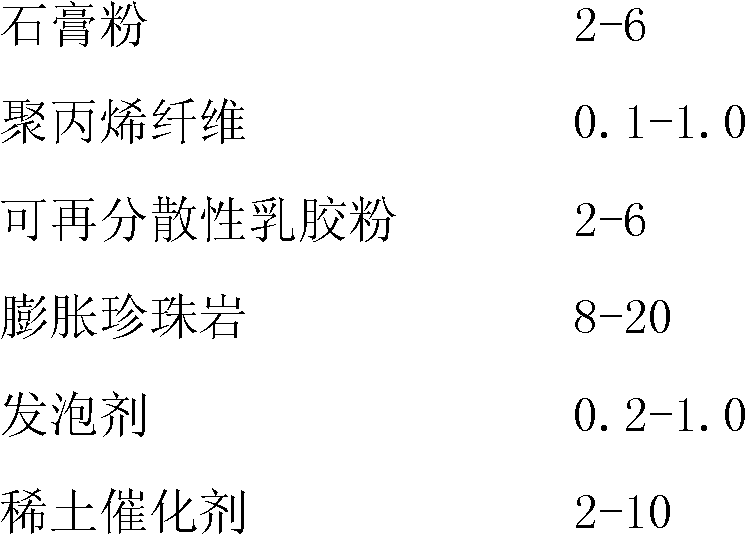

[0066] 1. Prepare materials according to the following proportions by weight

[0067]

[0068]

[0069] Wherein, the cement is Portland cement with a label of 42.5R; the fly ash is purchased from Fuzhou Huaneng Power Plant; the first-grade fly ash of Fuzhou Huaneng Power Plant; The density is 0.91g / cm 3 , its equivalent diameter is 18-48um; Described redispersible latex powder is VAC / VeoVa copolymerized dispersible latex powder (produced by Shanxi Sanwei Group Co., Ltd., model: SWF-04), its 50% aqueous solution viscosity 0.5-2.0Pa·s; the foaming agent is purchased from Jiangsu Qingting Detergent Co., Ltd. anionic surfactant foaming agent, the model is HF;; the rare earth catalyst is lanthanum chloride.

[0070] 2. Prepare mortar

[0071] 1) Add expanded perlite to the mixer, start the mixer, then add cement, fly ash, plaster of paris, polypropylene fiber, redispersible latex powder, rare earth catalyst, water in the stirring state, and stir evenly to obtain The mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com